Liquid type deet composition and preparation thereof

A composition and the technology of DEET, which are applied in the field of daily chemistry, can solve the problems of unstable solution system and difficulty in dissolving in water, and achieve good solution stability, small emulsified particles, and simple process production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

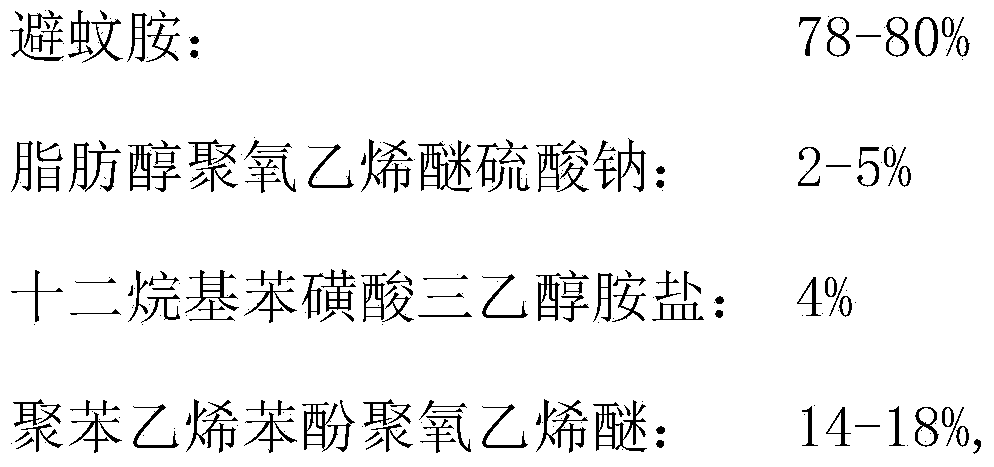

Method used

Image

Examples

Embodiment 1

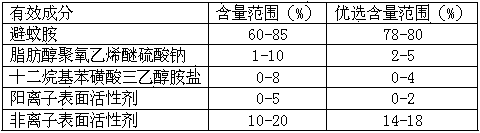

[0019] A water-based DEET composition is prepared by mixing 5% (mass percentage) of active components with water, wherein the effective components are obtained by mixing the content ratios of the components in Table 2.

[0020] Table 2 Active components and contents of the water-based DEET composition of Example 1

[0021] .

[0022] The preparation method of the aqueous type DEET composition of embodiment 1: put DEET, agricultural milk 600, AES, triethanolamine dodecylbenzenesulfonate into the stirring tank successively by the above-mentioned ratio in table 2, in Stir at a temperature of 20-30°C for 5-10 minutes, slowly add water to make a solution with an active component of 5% (mass percentage), continue stirring at a temperature of 30-60°C for 10-20 minutes, cool and stand to obtain A water-based DEET composition. The prepared product is safe and non-toxic, and the effective time of repelling mosquitoes is as long as 8 hours.

Embodiment 2

[0024] A water-based DEET composition is prepared by mixing 10% (mass percentage) of active components with water, wherein the effective components are obtained by mixing the content ratios of the components in Table 3.

[0025] Table 3 Active components and contents of the water-based DEET composition of Example 2

[0026] .

[0027] The preparation method of the water type DEET composition of embodiment 2: put DEET, OP-4, OP-10, AES, dodecylbenzenesulfonate triethanolamine salt into Stirring tank, stirring at a temperature of 20-30°C for 5-10 minutes, slowly adding water to make a solution with an effective component of 10% (mass percentage), and continuing stirring at a temperature of 30-60°C for 10-20 minutes, Cool and stand to obtain a water-based DEET composition. The prepared product is safe and non-toxic, and the effective time of repelling mosquitoes is as long as 12 hours.

Embodiment 3

[0029] A water-based DEET composition is prepared by mixing 20% (mass percentage) of active components with water, wherein the active components are obtained by mixing the components according to the content ratios in Table 4.

[0030] Table 4 Active components and contents of the formulation DEET composition of Example 3

[0031] .

[0032] The preparation method of the water type DEET composition of embodiment 3: successively make DEET, OP-4, AEO-7, AES, octadecylamine polyoxyethylene ether diquaternary ammonium by the above-mentioned ratio in table 4 Put the salt into the mixing tank, stir for 5-10 minutes at a temperature of 20-30°C, slowly add water to make a solution with an effective component of 20% (mass percentage), continue stirring at a temperature of 30-60°C for 10- After cooling for 20 min, the water-type DEET composition was obtained. The prepared product is safe and non-toxic, and the effective time of repelling mosquitoes is as long as 17 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com