Gas desulfurizing agent and preparation method thereof

A desulfurizer and gas technology, applied in the field of renewable sodium phosphate solution, can solve the problems of poor salt resistance and poor foaming ability, and achieve the effects of low cost, low energy consumption, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

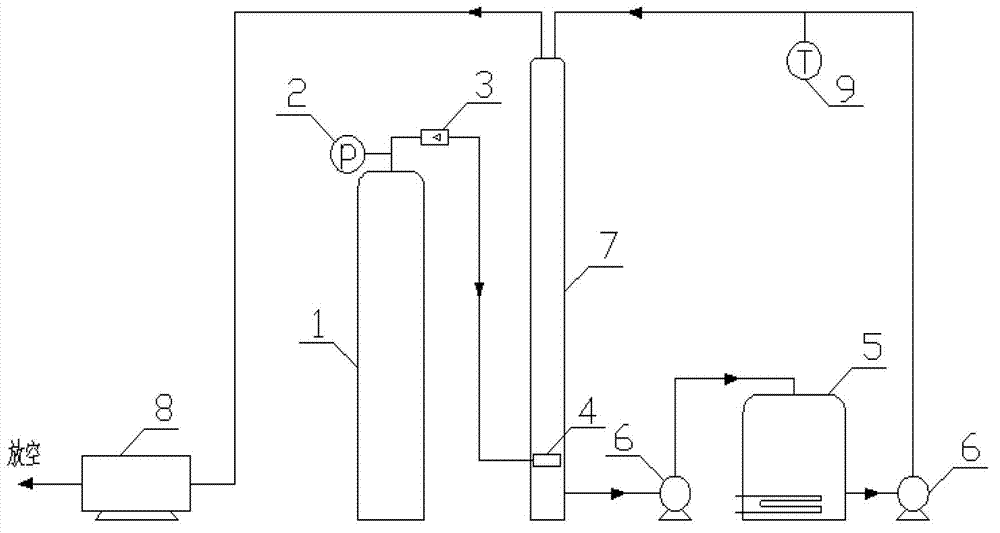

Image

Examples

Embodiment 1

[0025] Sodium phosphate dodecahydrate accounts for 3.0% (300g) of the mass percentage of the solution, 0.05% (5.2g) of lauryl alcohol, water (10000g), anionic surfactant sodium lauryl sulfate and nonionic surface The concentration of active agent alkyl polyglucoside is 5×10 -5 mol / L (mol). According to the above ratio, first dissolve sodium phosphate in water at 25~30°C, add foam stabilizer and surfactant, then stir for 20~30 minutes, add phosphoric acid aqueous solution to make the pH value 8.5~9.0, and prepare desulfurization solution.

Embodiment 2

[0027] Sodium phosphate dodecahydrate accounts for 23.0% (3000g) of the mass percentage of the solution, 0.05% (6.5g) of lauryl alcohol, water (10000g), anionic surfactant sodium lauryl sulfate and nonionic surface The concentration of active agent alkyl polyglucoside is 5×10 -5 mol / L (mol). According to the above ratio, first dissolve sodium phosphate in water at 25~30°C, add foam stabilizer and surfactant, stir for 20~30 minutes, add phosphoric acid aqueous solution to make the pH value 8.5~9.0, and prepare desulfurization solution.

Embodiment 3

[0029] Sodium phosphate dodecahydrate accounts for 23.0% (3000g) of the mass percentage of the solution, 0.1% (13g) of lauryl alcohol, water (10000g), anionic surfactant sodium lauryl sulfate and nonionic surfactant The concentration of alkyl polyglucoside was 12.5×10 -5 mol / L (mol). According to the above ratio, first dissolve sodium phosphate in water at 25~30°C, add foam stabilizer and surfactant, stir for 20~30 minutes, add phosphoric acid aqueous solution to make the pH value 8.5~9.0, and prepare desulfurization solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com