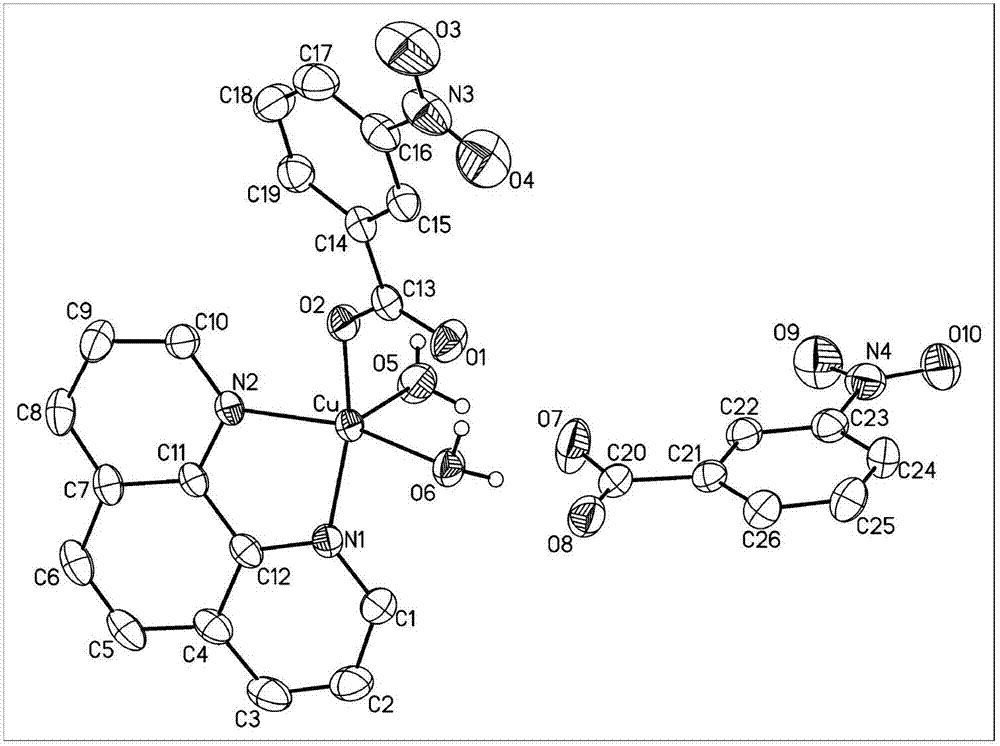

Copper complex ferroelectric functional material and preparation method thereof

A technology of ferroelectric functional materials and copper complexes, applied in the direction of copper organic compounds, etc., to achieve the effect of easy industrialization, low equipment requirements, and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

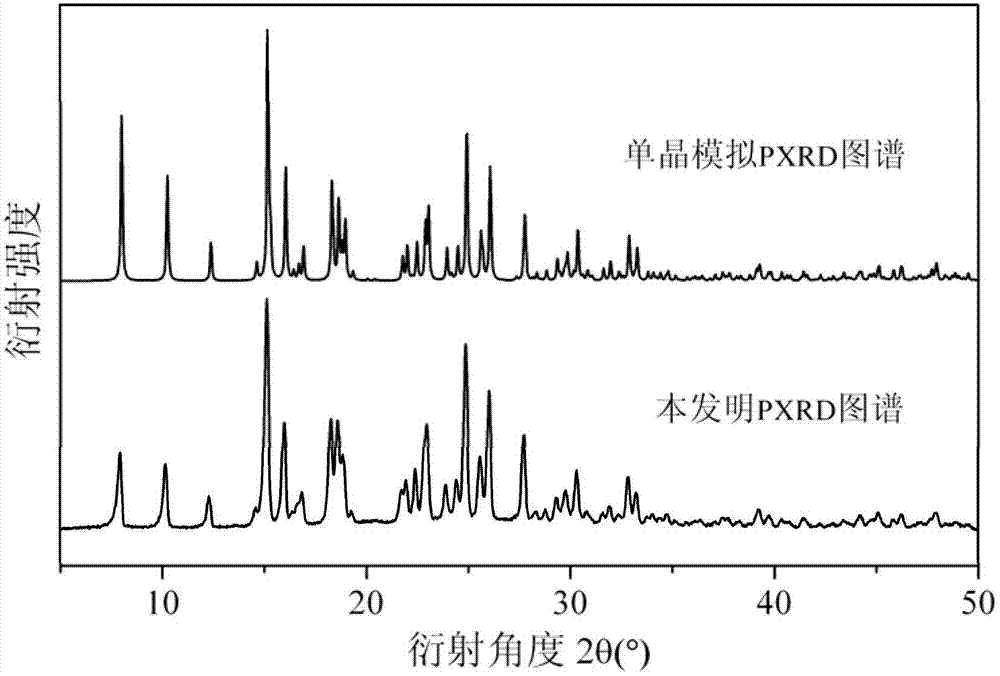

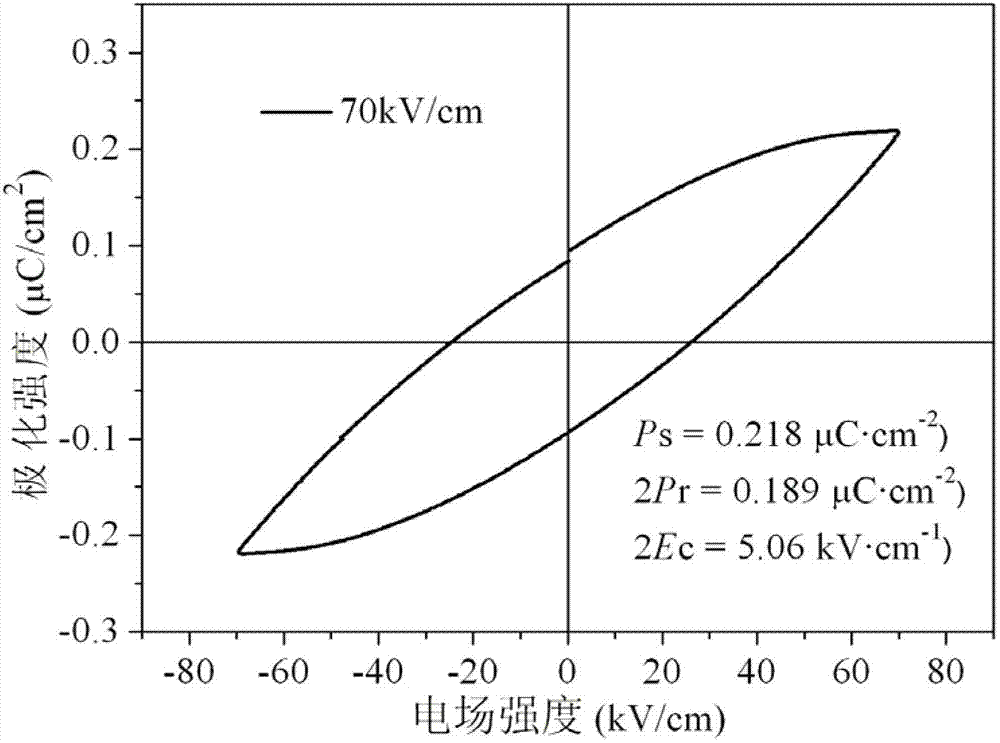

Embodiment 1

[0017] Dissolve 0.1mol of m-nitrobenzoic acid in a mixed solvent composed of 0.5L deionized water and 0.5L ethanol, stir until completely dissolved, and obtain a m-nitrobenzoic acid solution for use; the copper ion is 0.05mol of CuCl 2 2H 2 O was dissolved in deionized water to form CuCl 2 solution, then dropwise add a sodium hydroxide solution with a concentration of 1mol / L until dark green (Cu(OH) 2 ·xH 2 O) The precipitate is completely precipitated, and the dark green precipitate is centrifuged and washed with distilled water for 5 times in total. The washed dark green precipitate is immediately added to the above-mentioned m-nitrobenzoic acid solution, and stirred for 5 to 40 minutes to obtain light blue Color copper m-nitrobenzoate suspension; then add 0.05mol o-phenanthroline, stir the light blue suspension into dark blue suspension, continue stirring for 20-40min, filter, precipitate and dry to obtain Dark blue powder crystal, the purity of the dark blue powder crys...

Embodiment 2

[0019] Substantially the same as Example 1, the only difference is that the molar weight of m-nitrobenzoic acid is 0.05mol, CuCl 2 2H 2 O is composed of copper ions as 0.025mol Cu(OAC) 2 ·H 2 O substitution, the molar weight of o-phenanthroline is 0.025mol.

Embodiment 3

[0021] Substantially the same as Example 1, except that the molar weight of m-nitrobenzoic acid is 0.08mol, CuCl 2 2H 2 O from CuSO with 0.04 mol of copper ions 4 ·5H 2 O substitution, the molar weight of o-phenanthroline is 0.04mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturated polarization | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com