Preparation method of acrylic acid moisturizing composite material

A composite material, acrylic technology, applied in the field of new materials, to achieve the effect of easy molding, good water retention effect and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The method for the preparation of embodiment 1 acrylic acid moisturizing composite material

[0017] Silica gel powder preparation: take 150ml of water glass and place it in a container, slowly add H with a concentration of about 25% under stirring conditions 2 SO 4 Solution to water glass to form a gel; dry the water glass gel at 50-65°C for 8-10 hours to form white loose particles, grind it into 80-200 mesh powder with a mortar for later use;

[0018] Preparation of acrylic acid moisture-retaining composite material sample: configure NaOH solution according to the mass ratio of water and sodium hydroxide of 12:1; Stir well; then add N,N-methylene acrylamide, ammonium persulfate, bentonite and silica gel powder according to the mass parts shown in Table 1, and stir well; heat at 70-80°C, after fully After the reaction, the sample was taken out from the beaker and placed in an oven, and dried at 50-60°C for 2-6 hours to constant weight.

[0019] Table 1 Experimental ...

Embodiment 2

[0021] The structure and performance of embodiment 2 acrylic acid moisturizing composite material

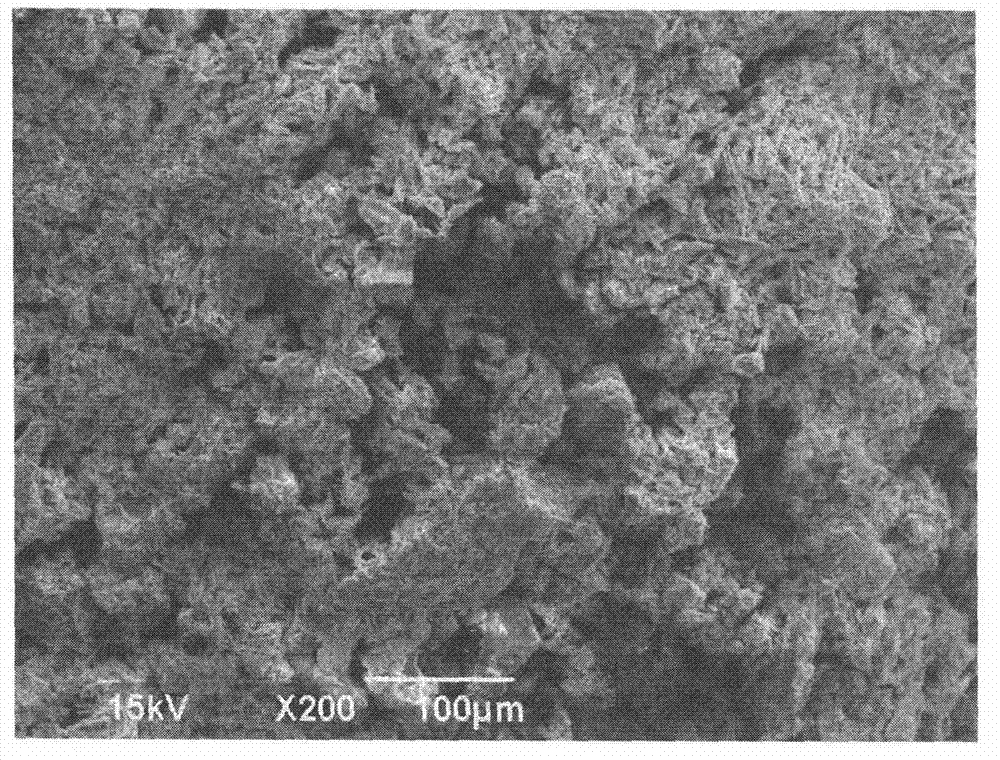

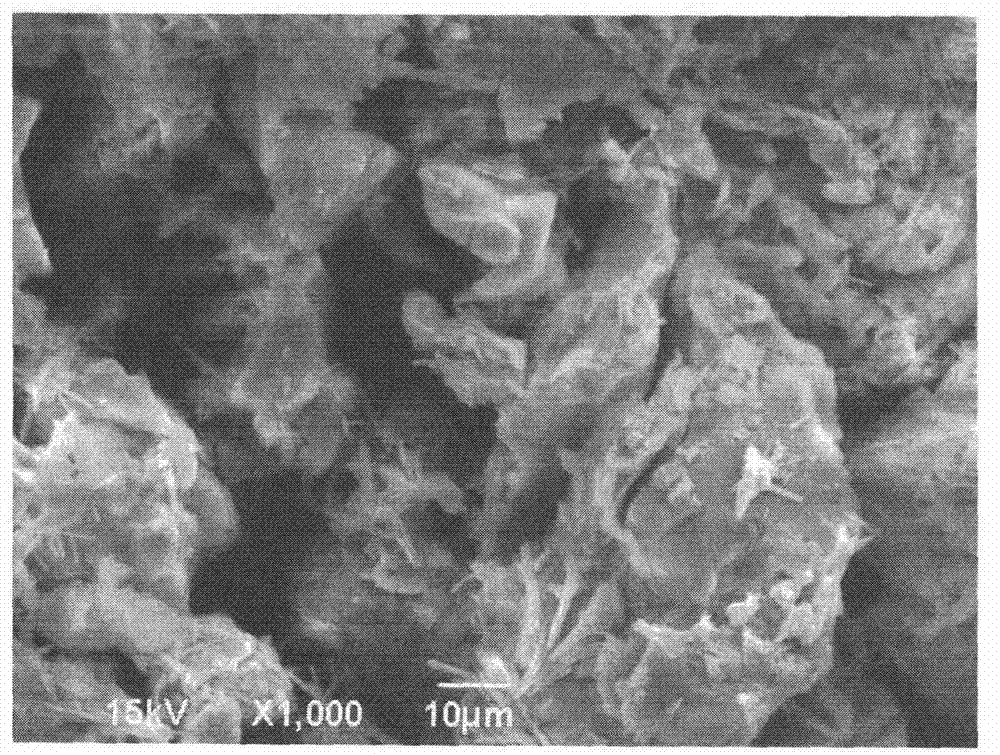

[0022] The structure of the composite material: the acrylic moisture-retaining composite material presents a porous structure, such as figure 1 Shown is the electron micrograph of the composite material.

[0023] Water absorption and dehydration properties of composite materials: As shown in the above-mentioned Table 1, the content of silica gel powder in the first 5 groups of experiments increased sequentially, and the content of bentonite in the last 5 groups of experiments increased in sequence, and water absorption and dehydration experiments were carried out at 20°C and 40°C respectively. As shown in Table 2 and Table 3.

[0024] Table 2 Result table of water absorption and dehydration experiment at 20°C (unit: multiple of sample weight)

[0025] Experiment number

[0026] 4

[0027] Table 3 40°C water absorption and dehydration test results table (u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com