A kind of preparation method and application of modified alkylphenol formaldehyde tackifying resin

A technology of modification of alkyl phenolic resin, applied in the field of phenolic resin, can solve problems such as energy loss, increased fuel consumption, and accelerated aging of rubber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

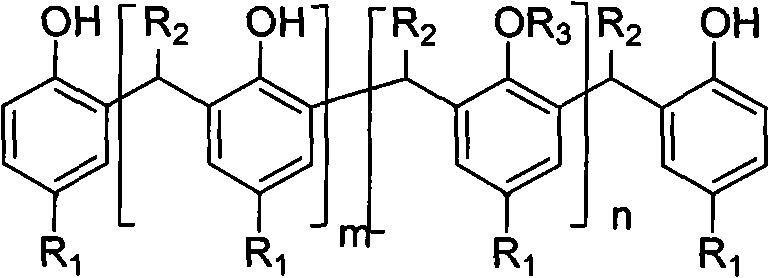

Method used

Image

Examples

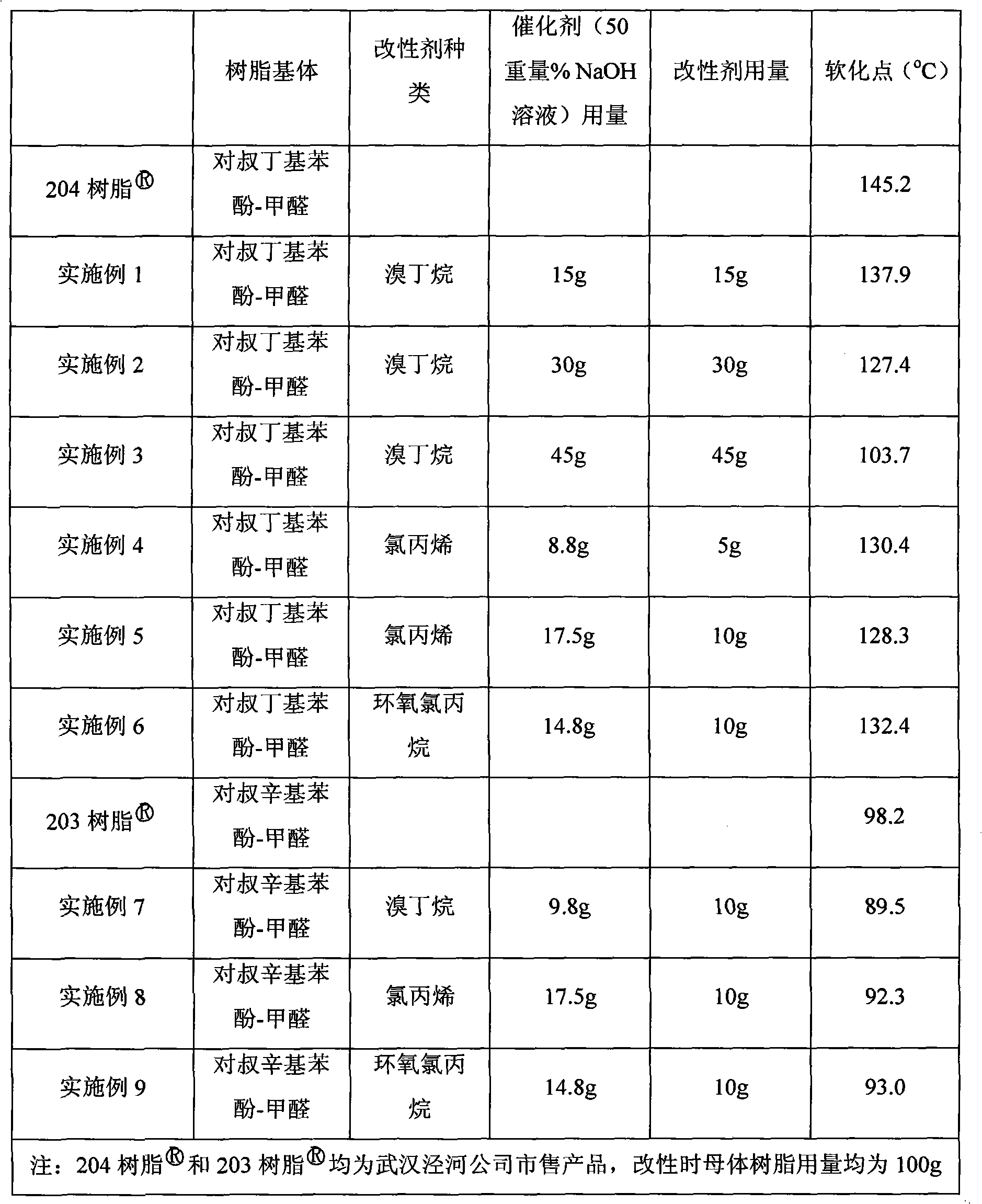

Embodiment 1

[0028] With 100g commercially available p-tert-butylphenol-formaldehyde resin (204 resin Softening point 145.2 ℃) is added in the mixed solvent of 50mL toluene and 50mL ethanol, be warmed up to 60 ℃; After the resin is completely dissolved, add 15g concentration and be the sodium hydroxide aqueous solution of 30% by weight, start dripping bromobutyl after 15 minutes of reaction Add 15g of alkane, drop it within 30 minutes; keep the reaction at 60°C, add a small amount of dilute hydrochloric acid to neutralize to a pH value of 6-8, add 50mL of toluene to extract after 5h, wash with 100mL of distilled water, and separate the water phase components; collect After the oil phase is composed, the temperature is raised to 180°C and the solvent in the system is distilled off under normal pressure, and then further distilled at a pressure of 2-3kPa for 15 minutes to completely remove the solvent and volatile substances in the resin to obtain the modified alkylphenol-formaldehyde resin....

Embodiment 10

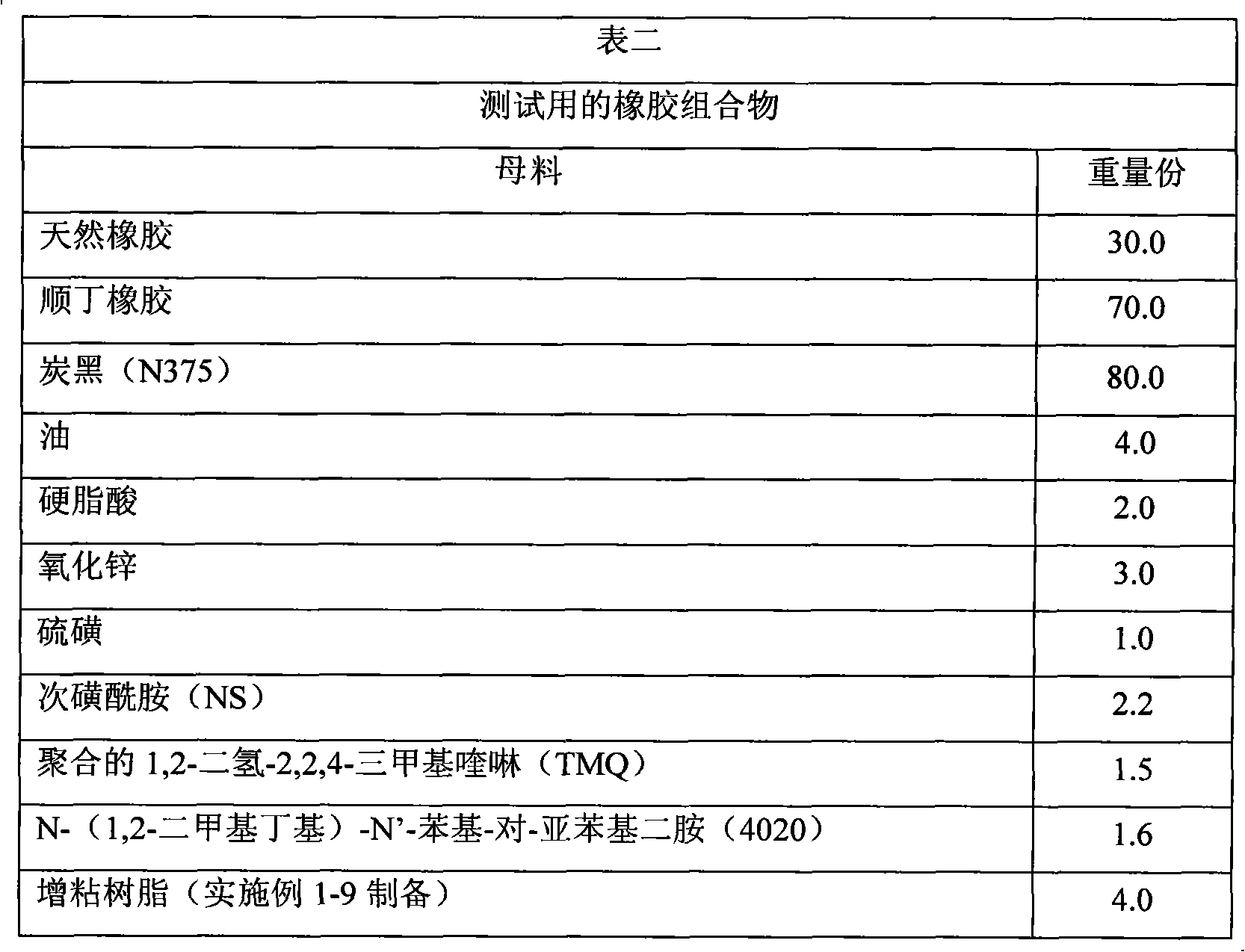

[0035] The preparation of the rubber composition is carried out according to the formula shown in Table 2

[0036]

[0037] The resins prepared according to the examples were evaluated in a mixture of natural rubber (Malaysian Standard Rubber, SMR20) and butadiene rubber (Beijing Yanshan Petrochemical Co., Ltd., BR9000) to evaluate and compare their performance relative to the tackifying resin before modification.

[0038] In the first stage, natural rubber, butadiene rubber, carbon black, oil, zinc oxide and stearic acid were mixed in a Banbury mixer at 150°C to make a rubber masterbatch. Then in the second stage, the modified tackifying resin, anti-aging agent 4020 and TMQ prepared according to the method in the example were mixed into an appropriate amount of rubber masterbatch at about 140°C. At about 100°C, the insoluble sulfur and sulfenamide accelerator NS were added to the third stage open mill mixer and leveled. The test compositions were stored at constant room tem...

Embodiment 11

[0040] In this example, a rubber processing analyzer (RPA2000) by Alpha Technology was used to measure dynamic mechanical properties.

[0041] The RPA2000 is capable of testing uncured and cured rubber with high repeatability and reproducibility. Available tests and subtests include frequency sweep at constant temperature and strain, sulfur change at constant temperature and frequency, strain sweep at constant temperature and frequency, and temperature sweep at constant strain and frequency. The high accuracy of the instrument enables repeated testing of changes in the properties of glue samples. Storage modulus and Tanδ data are measured by strain sweep and frequency sweep of vulcanized rubber samples at 60°C. The test data are listed in Table III.

[0042] Table 3. Properties of materials obtained by testing modified alkylphenolic resins

[0043]

[0044] The above data clearly show that the vulcanizate compound added with the resin of the present invention exhibits go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com