Flexible ultraviolet-curing ink-jet ink and preparation method thereof

An inkjet ink, ultraviolet light technology, applied in the directions of ink, application, coating, etc., can solve the problem that the ink is suitable for flexible materials, etc., and achieve the effect of good flexibility, good development prospects, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

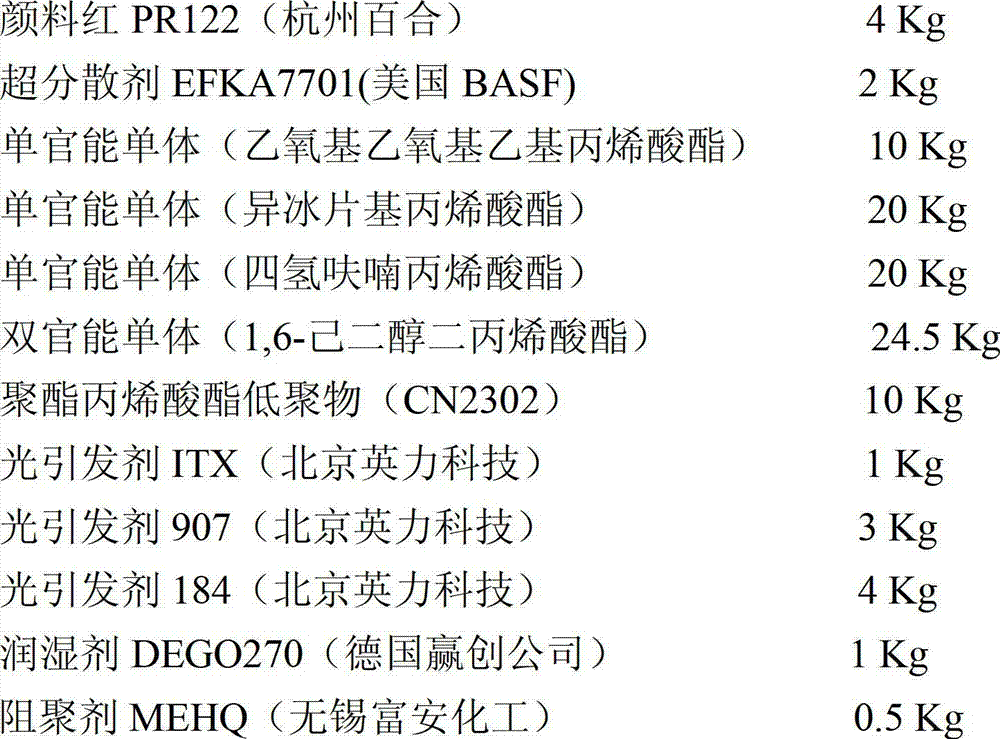

Embodiment 1

[0029]

[0030] Wherein, photoinitiator ITX is isopropylthioxanthone; Photoinitiator 907 is 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-acetone; Photoinitiator 184 For 1-hydroxycyclohexyl phenyl ketone. The polymerization inhibitor MEHQ is 1,4-methoxyphenol.

[0031] A method for preparing a flexible UV-curable inkjet ink, comprising the following steps: first mixing and dispersing a mixture of a pigment, a dispersant, a part of a monofunctional monomer, a part of a bifunctional monomer, a part of a trifunctional monomer, and a polymerization inhibitor, and then Grind, then add the remaining reactive monomers, photoinitiators, wetting agents, and polymerization inhibitors, heat to 40-60°C, mix evenly by high-speed stirring, adjust the viscosity, color concentration, and surface tension of the ink, and finally use the filter element Filtration is carried out with a filtration accuracy of 0.5 micron to obtain a flexible UV-curable inkjet ink.

[0032] The grinding and di...

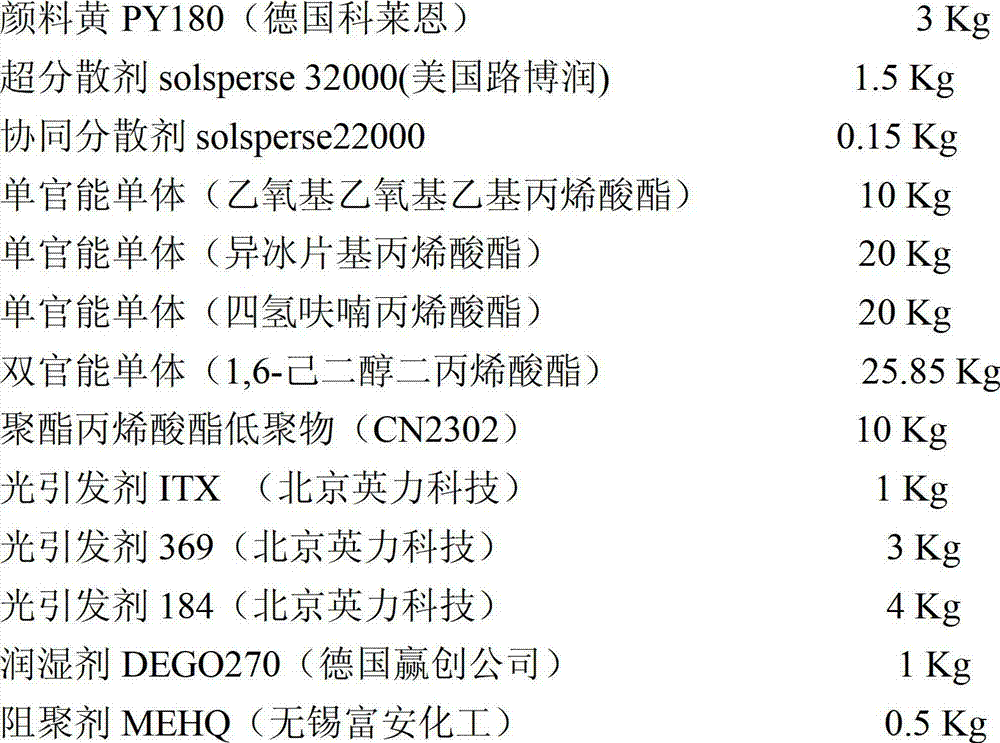

Embodiment 2

[0034]

[0035] Wherein, photoinitiator 369 is 2-phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone;

[0036] The preparation method of the flexible UV-curable inkjet ink is the same as the first embodiment.

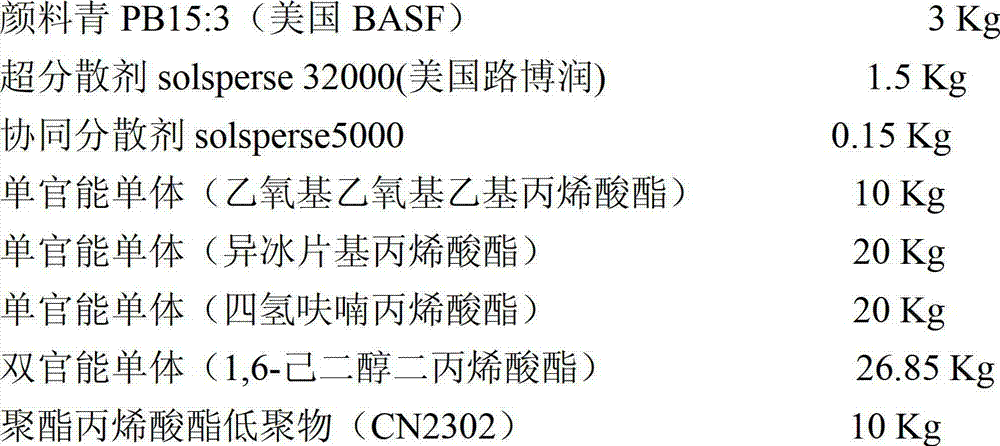

Embodiment 3

[0038]

[0039]

[0040] The preparation method of the flexible UV-curable inkjet ink is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com