High-thermal conductivity conductive silver adhesive and preparation method thereof

A conductive silver glue, high thermal conductivity technology, applied in conductive adhesives, adhesives, epoxy resin glue and other directions, can solve the problem of not mentioning Ag powder, increase the contact area between silver powder and silver powder, etc., to achieve simple production equipment , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix 5 g of silicone resin and 0.25 g of heat-sensitive platinum catalyst in a mortar to prepare a matrix resin with uniform components.

[0038] (2) After mixing 0.5 g of graphite and 10 ml of acetone, sonicate at 20 to 50° C. for 3 to 6 hours, let stand for 12 hours, take the upper layer suspension, centrifuge and distill to obtain a graphene solution.

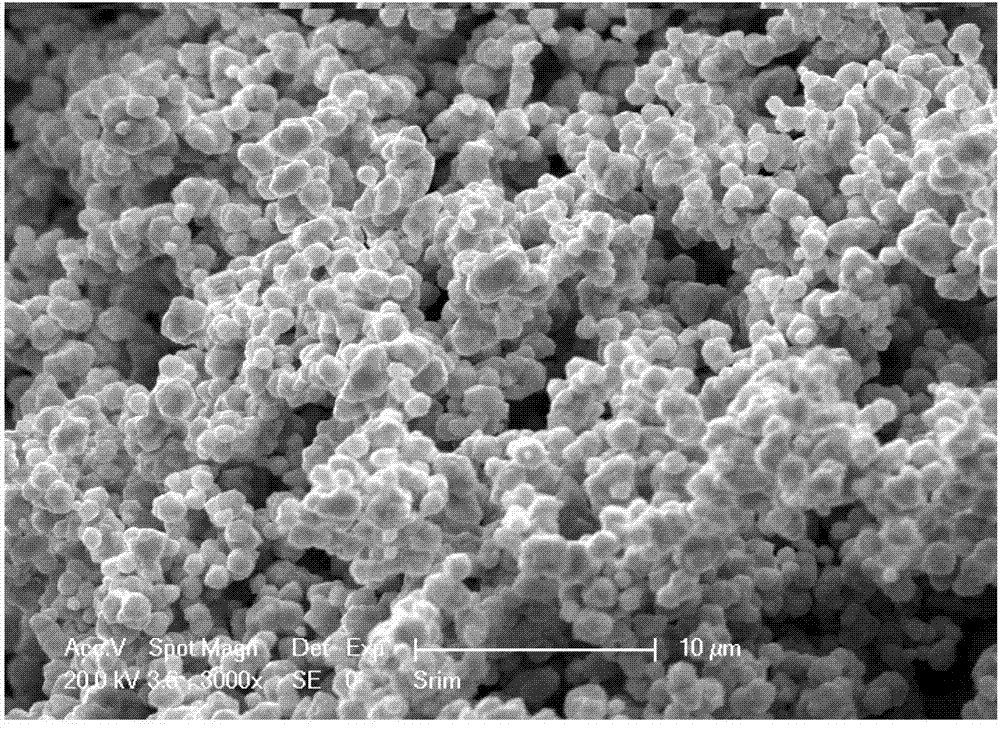

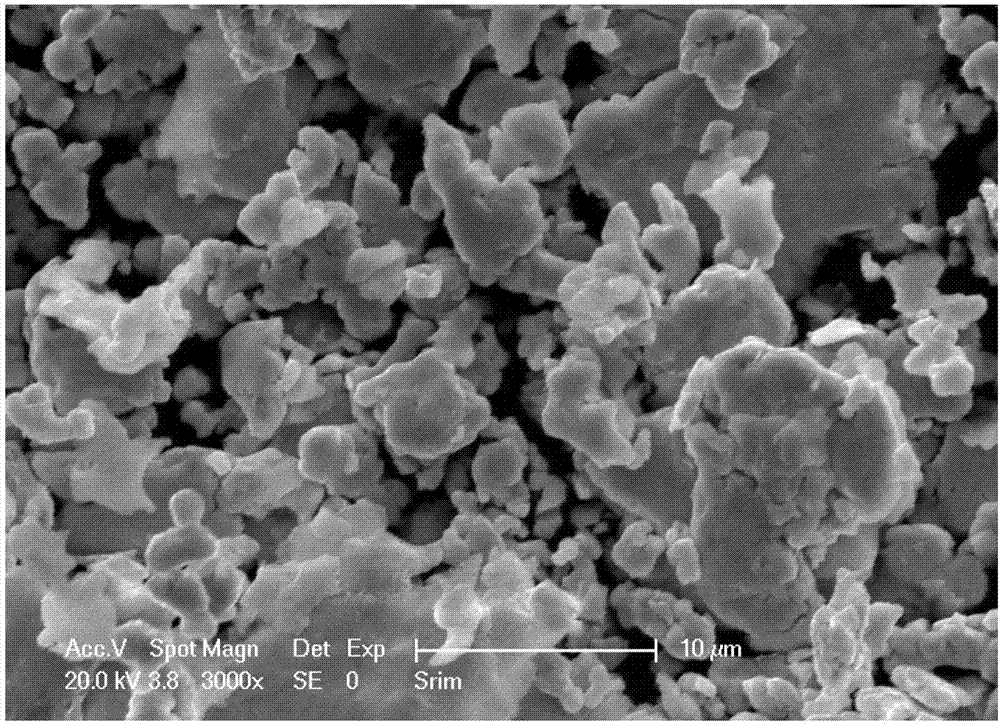

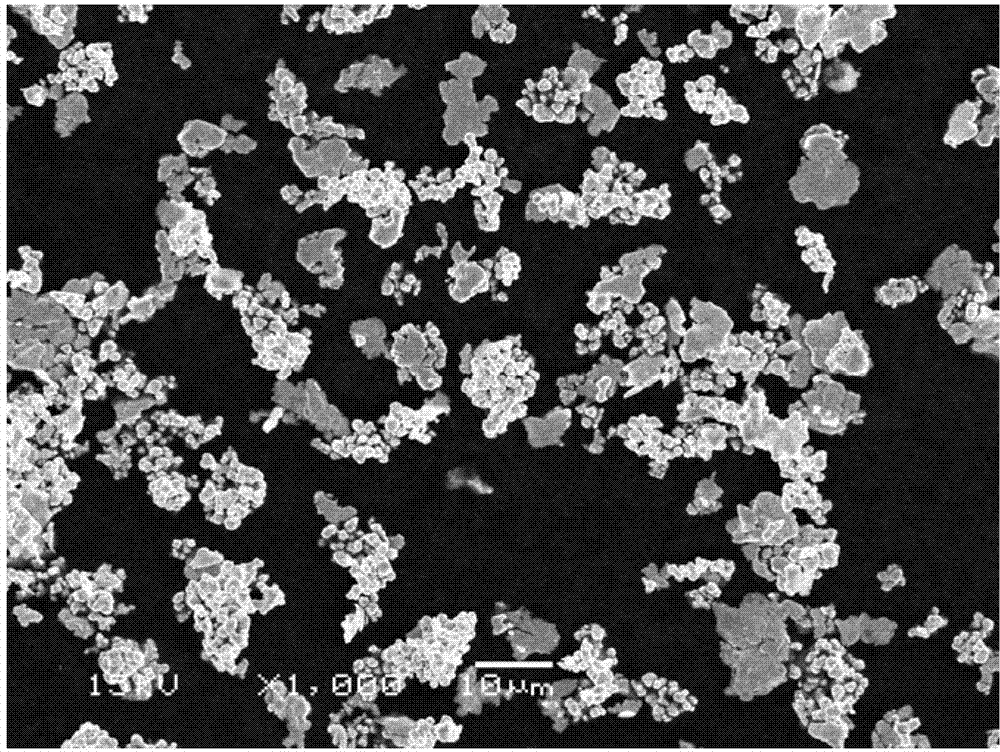

[0039] (3) Weigh 10g of flake silver, 10g of spherical silver and 0.3g of graphene solution into a beaker, add 100ml of acetone, disperse with ultrasound, ultrasonic for 15min, then centrifuge and dry to obtain conductive filler and graphene mixtures such as image 3 shown.

[0040](4) Mix the conductive filler and the matrix resin by three rollers, and add 0.75g of vinylmethylsiloxane and 0.65g of fumed silica during the mixing process.

[0041] A high thermal conductivity thermally conductive silver glue has been prepared by the above method, and its volume resistivity is 2 × 10 -5 (Ω·cm) -1 , the thermal con...

Embodiment 2

[0043] (1) Mix 5 g of epoxy resin and 0.25 g of imidazole curing agent in a mortar to prepare a matrix resin with uniform components.

[0044] (2) After mixing 0.5 g of graphite and 10 ml of acetone, sonicate at 20 to 50° C. for 3 to 6 hours, let stand for 12 hours, take the upper layer suspension, centrifuge and distill to obtain a graphene solution.

[0045] (3) Weigh 10g of flake silver, 10g of spherical silver and 0.3g of graphene solution into a beaker, add 100ml of acetone, disperse by ultrasonic, ultrasonic for 15min, then centrifuge and dry.

[0046] (4) Mix the conductive filler and the matrix resin by three rollers, and add 0.68g of a mixture of diethylene glycol monoethyl ether and ethylene glycol ether at a volume ratio of 3:1 during the mixing process, and then add 0.65g of Fumed silica, can be.

[0047] A high thermal conductivity thermally conductive silver glue was prepared by the above method, and its volume resistivity was 2.48×10 -5 (Ω·cm) -1 , the therma...

Embodiment 3

[0049] (1) Mix 10 g of silicone resin and 0.5 g of heat-sensitive platinum catalyst in a mortar to prepare a matrix resin with uniform components.

[0050] (2) After mixing 1 g of graphite and 20 ml of acetone, ultrasonicate at 20 to 50° C. for 3 to 6 hours, let stand for 12 hours, take the upper suspension, centrifuge and distill to obtain a graphene solution.

[0051] (3) Weigh 20g of flake silver, 10g of spherical silver and 0.6g of graphene solution into a beaker, add 100ml of acetone, disperse by ultrasonic, ultrasonic for 15min, then centrifuge and dry.

[0052] (4) Mix the conductive filler and the matrix resin by three rollers, and add 2.5g of a mixture of diethylene glycol monoethyl ether and ethylene glycol ether at a volume ratio of 3:1 during the mixing process, and then add 1.25g of Organic bentonite, can be.

[0053] A high thermal conductivity thermally conductive silver glue has been prepared by the above method, and its volume resistivity is 3.5×10 -5 (Ω·cm)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com