High-water content wax-containing crude oil flowing improver

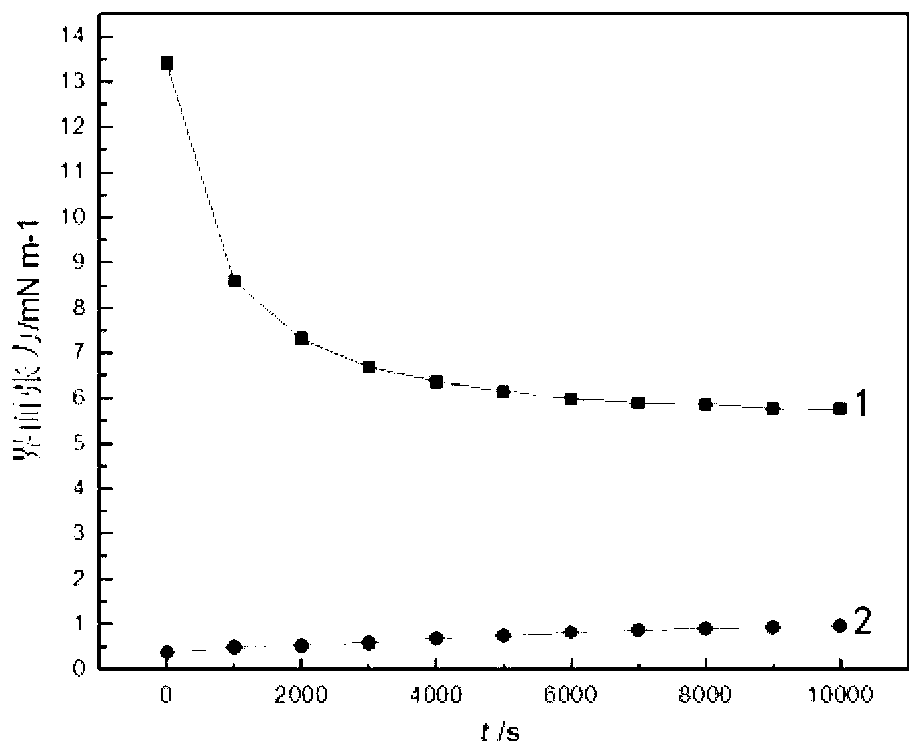

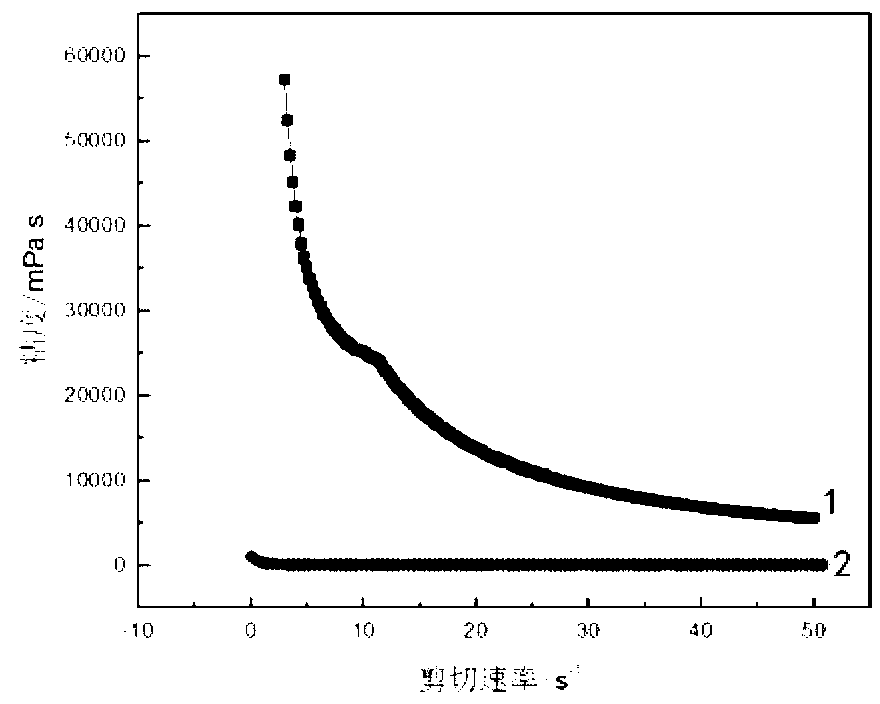

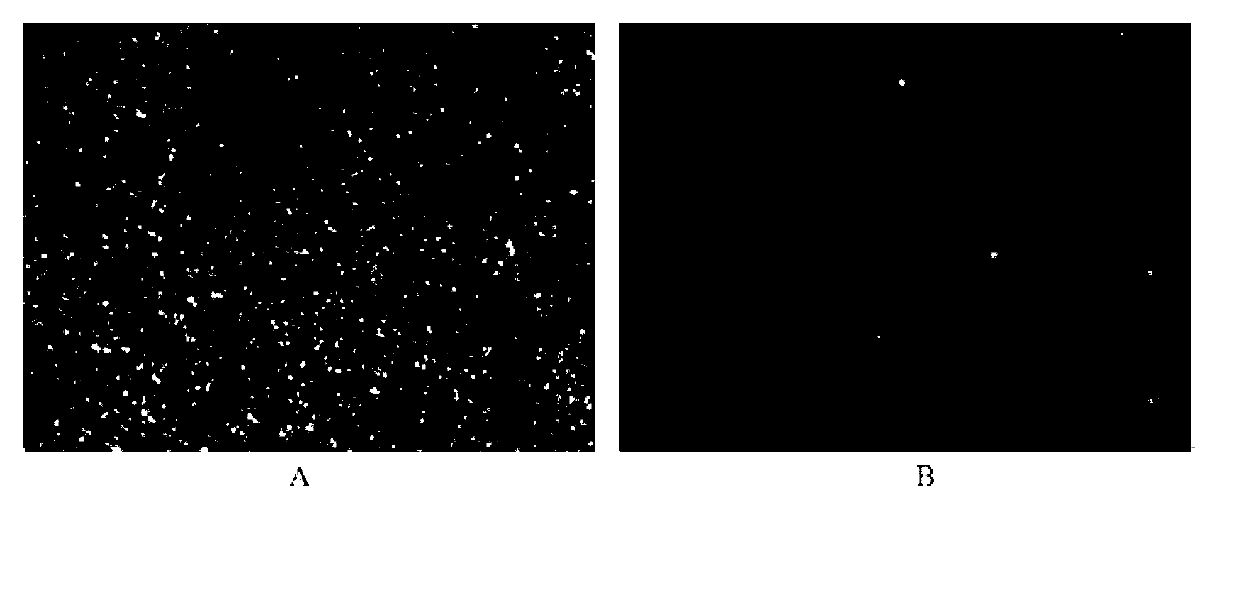

A flow improver, crude oil technology, applied in chemical instruments and methods, pipeline systems, gas/liquid distribution and storage, etc. Modification effect, increasing interfacial viscosity, reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The flow improver for high water content and waxy crude oil provided in this example is composed of Niner, sodium oleate and water, and the mass ratio of Niner, sodium oleate and water is: Niner: sodium oleate: water =7.7:3:92.

[0018] The preparation method of the high water content and waxy crude oil flow improver provided in this example: take 92 kg of hot water at a temperature of 50 ° C, first add 7.7 kg of Ninar to the water, stir, fully dissolve, and then add 3 kg of oil Sodium acid, continue to stir until it is completely dissolved evenly, and a flow improver for high water content and waxy crude oil is obtained.

Embodiment 2

[0020] The flow improver for high water content and waxy crude oil provided in this example is composed of Niner, sodium oleate and water, and the mass ratio of Niner, sodium oleate and water is: Niner: sodium oleate: water =6:3:94.

Embodiment 3

[0022] The flow improver for high water content and waxy crude oil provided in this example is composed of Niner, sodium oleate and water, and the mass ratio of Niner, sodium oleate and water is: Niner: sodium oleate: water =10:1:90.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com