Non-oriented silicon steel for electric drive motor and production method thereof

An oriented silicon steel, electric drive technology, applied in the field of non-oriented silicon steel, can solve the problem of high alloy cost, achieve the effect of high yield, lower cost and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below:

[0044] Table 1 is the component value list of each embodiment of the present invention;

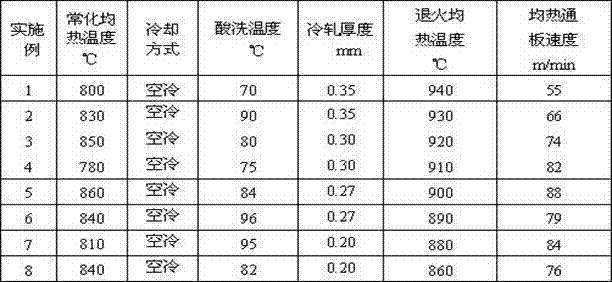

[0045] Table 2 is the list of main process parameters of each embodiment of the present invention;

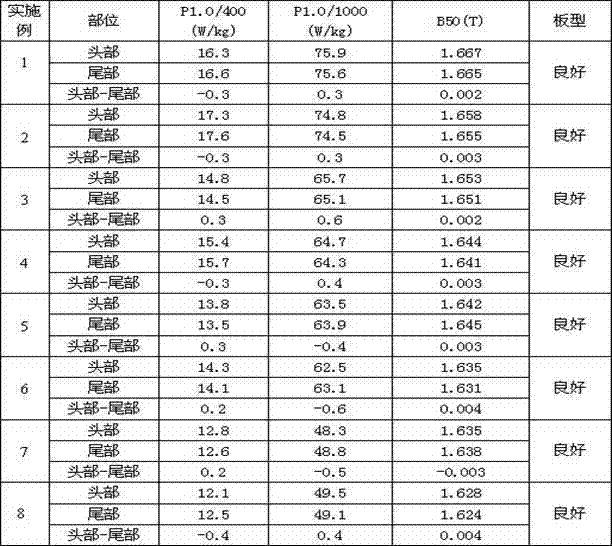

[0046] Table 3 is a list of magnetic performance testing conditions of various embodiments of the present invention.

[0047] Each embodiment of the present invention is produced according to the following steps:

[0048] Its steps:

[0049] 1) Vacuum furnace smelting and pouring into billets;

[0050] 2) Heating the slab, controlling the heating temperature at 1050-1150°C, and the heating time is 60-12 minutes;

[0051] 3) Carry out rolling, control the finish rolling temperature of rough rolling not lower than 900°C, rough rolling plate thickness not lower than 25mm, rough rolling reduction rate not lower than 80%; control finish rolling finish rolling temperature not lower than 750°C, Control the total reduction rate of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com