Thermal annealing acid-washing method of stainless steel wide and thick plate coil

A stainless steel and thermal annealing technology, applied in the field of metallurgy, can solve problems such as poor surface quality, and achieve the effect of improving product yield, excellent surface quality and material properties, and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

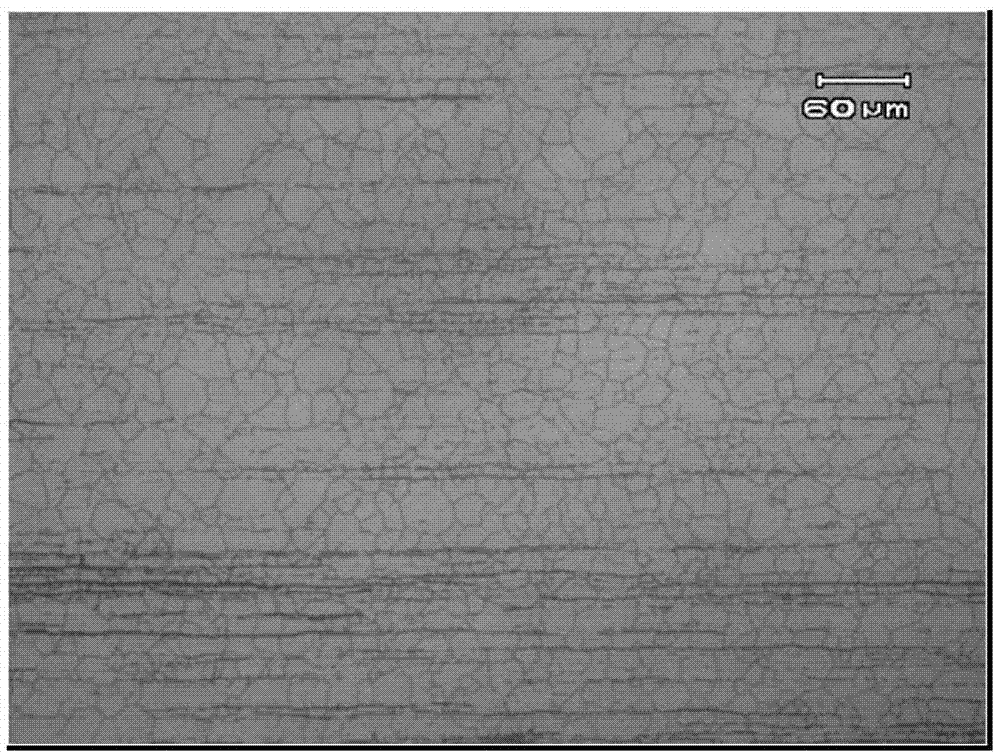

[0024] This embodiment provides a thermal annealing and pickling method for stainless steel wide and thick plate coils. The thickness of the stainless steel wide and thick plate is 16.0mm, the width is 1500mm, and the steel type is SUS304. The thermal annealing and pickling method comprises the following steps:

[0025] Entrance uncoiling of stainless steel wide and thick plate coils;

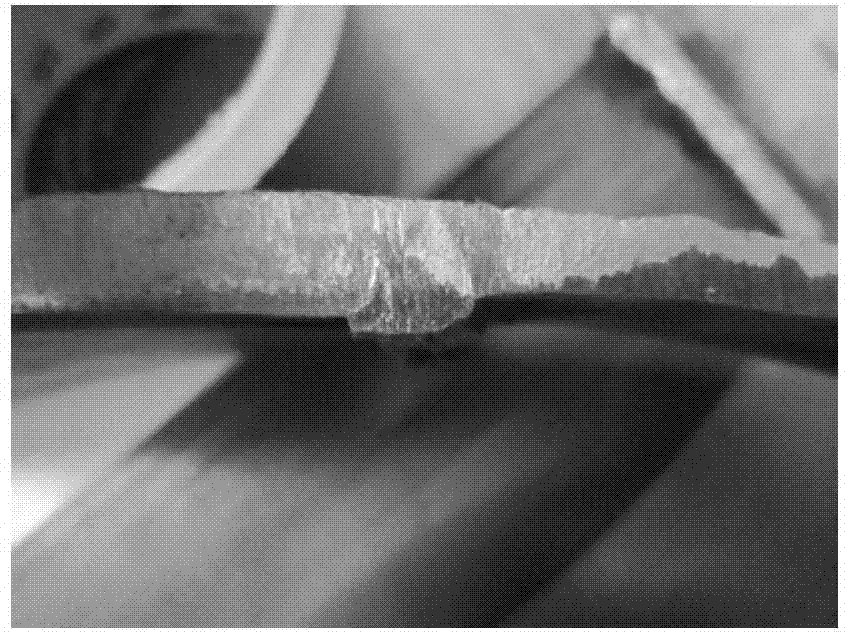

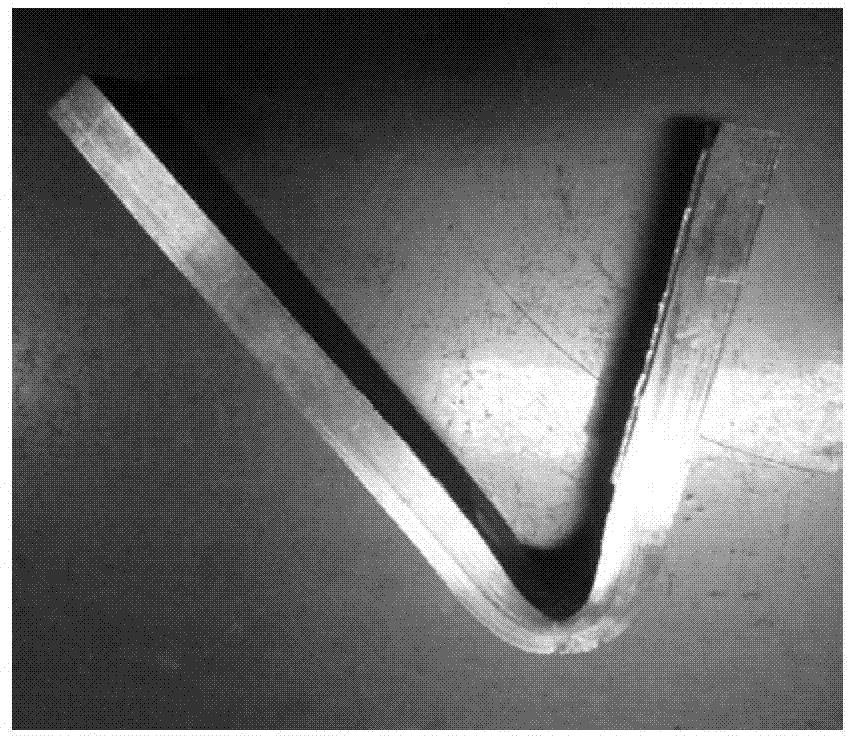

[0026] Pass the stainless steel wide and thick plate to the welding machine, and use double welding torches for welding. The voltage of the welding current is controlled at 38V, the welding speed is controlled at 0.35m / min, the diameter of the welding wire is 2.0mm, and the initial welding beam groove depth is 1.0mm. In the future, the groove can be polished after wear, and the deepest can not exceed 1.5mm; after the welding is completed, confirm the quality of the weld seam, the quality of the weld seam is intact, the production line is running, and enter the annealing section;

[0027] Anneal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com