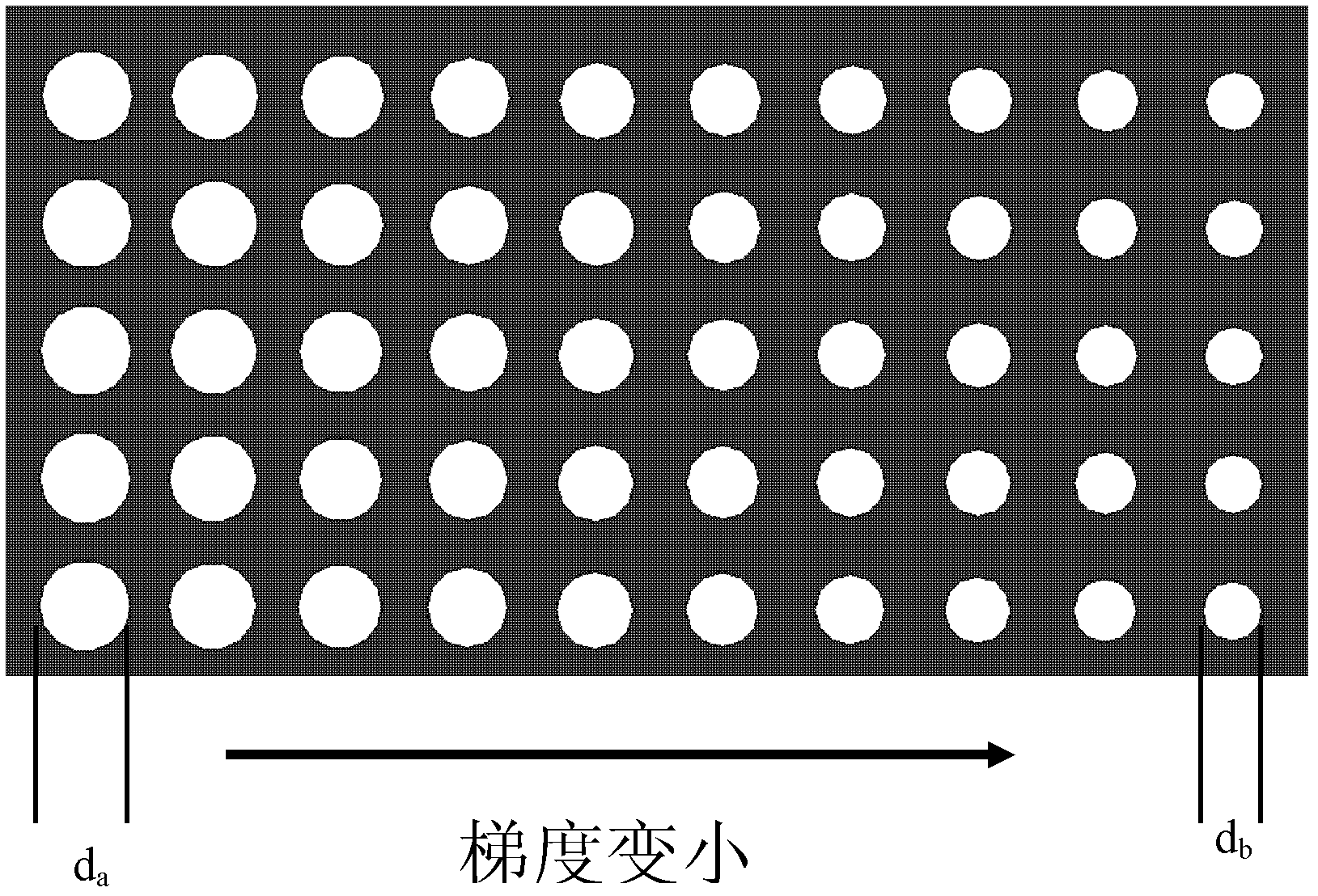

Preparation method for anode alumina template having gradient nanometer pore size

A technology of anodized aluminum and aluminum oxide templates, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problem of poor uniformity of gradient nanopores, complicated preparation process, non-perpendicular pores and anodized aluminum surfaces, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

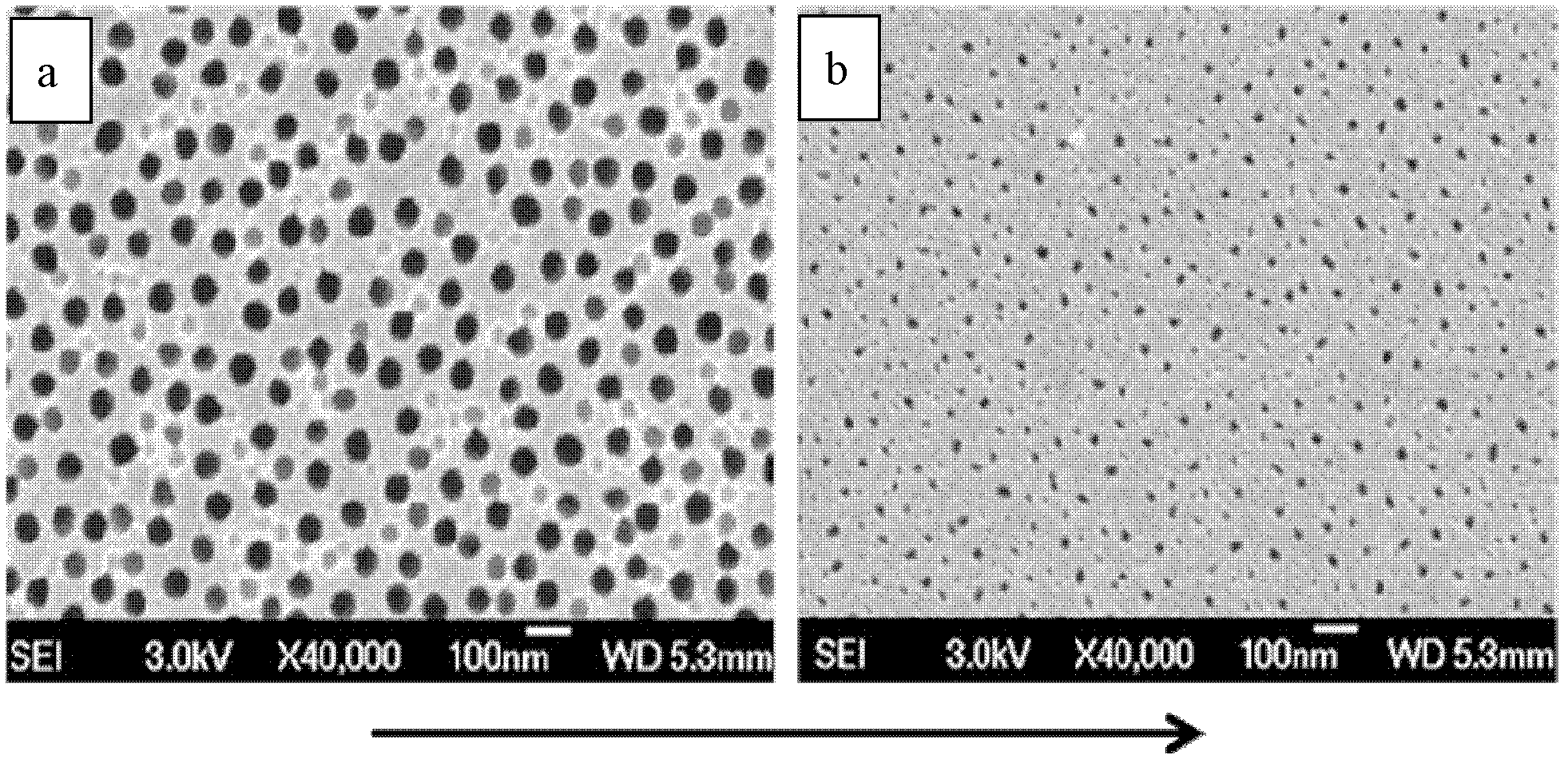

Embodiment 1

[0018] (1) Soak an aluminum sheet with a purity of 99.999% in an acetone solution with a mass fraction of 95% for degreasing treatment, take it out, and then soak it in an aqueous NaOH solution with a mass fraction of 5% for 5 minutes to remove the surface of the aluminum sheet. The oxide layer; take it out and rinse it with distilled water, anneal in the air at 500 ° C for 10 hours and cool with the furnace; then at 0 ° C, at C 2 h 5 OH and HClO 4 Mixed solution [V(C 2 h 5 OH): V(HClO 4 )=4:1], carry out constant voltage (12V) electrochemical polishing for 3 to 5 minutes to remove the oxide layer on the surface of the aluminum sheet and improve the smoothness of the surface; then in 0.3mol / L of H 2 C 2 o 4 Anodic oxidation was carried out in aqueous solution (constant DC voltage 40V, anodic oxidation at 0°C for 6 hours). Dip the aluminum sheet template obtained after oxidation into H 3 PO 4 and H 2 CrO 4 In the mixture (H 3 PO 4 The mass fraction in the mixture i...

Embodiment 2

[0021] A commercially available porous anodized aluminum template was immersed in 30% H 2 C 2 o 4 In aqueous solution, H 2 C 2 o 4 The temperature of the aqueous solution was controlled at 20°C, and one end of the porous anodized aluminum template was clamped with a puller, and the porous anodized aluminum template was pulled from the H 2 C 2 o 4 Extracted from the aqueous solution to obtain an anodized aluminum template with a nano-pore diameter with a gradient change in the pore size of the lower part and the upper part.

Embodiment 3

[0023] A commercially available porous anodized aluminum template was immersed in 1% H 2 SO 4 In aqueous solution, H 2 SO 4 The temperature of the aqueous solution was controlled at 80°C, and one end of the porous anodized aluminum template was clamped with a puller, and the porous anodized aluminum template was pulled from the H 2 SO 4 Extracted from the aqueous solution to obtain an anodized aluminum template with a nano-pore diameter with a gradient change in the pore size of the lower part and the upper part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com