Suction and conveying device of sludge pipeline

A technology for pipeline transportation and silt, applied in water supply devices, waterway systems, earth movers/shovels, etc., can solve the problem of non-polluting and non-polluting feeding, ensure reliable conversion and continuous transportation, and overcome viscous properties. , the effect of wall friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

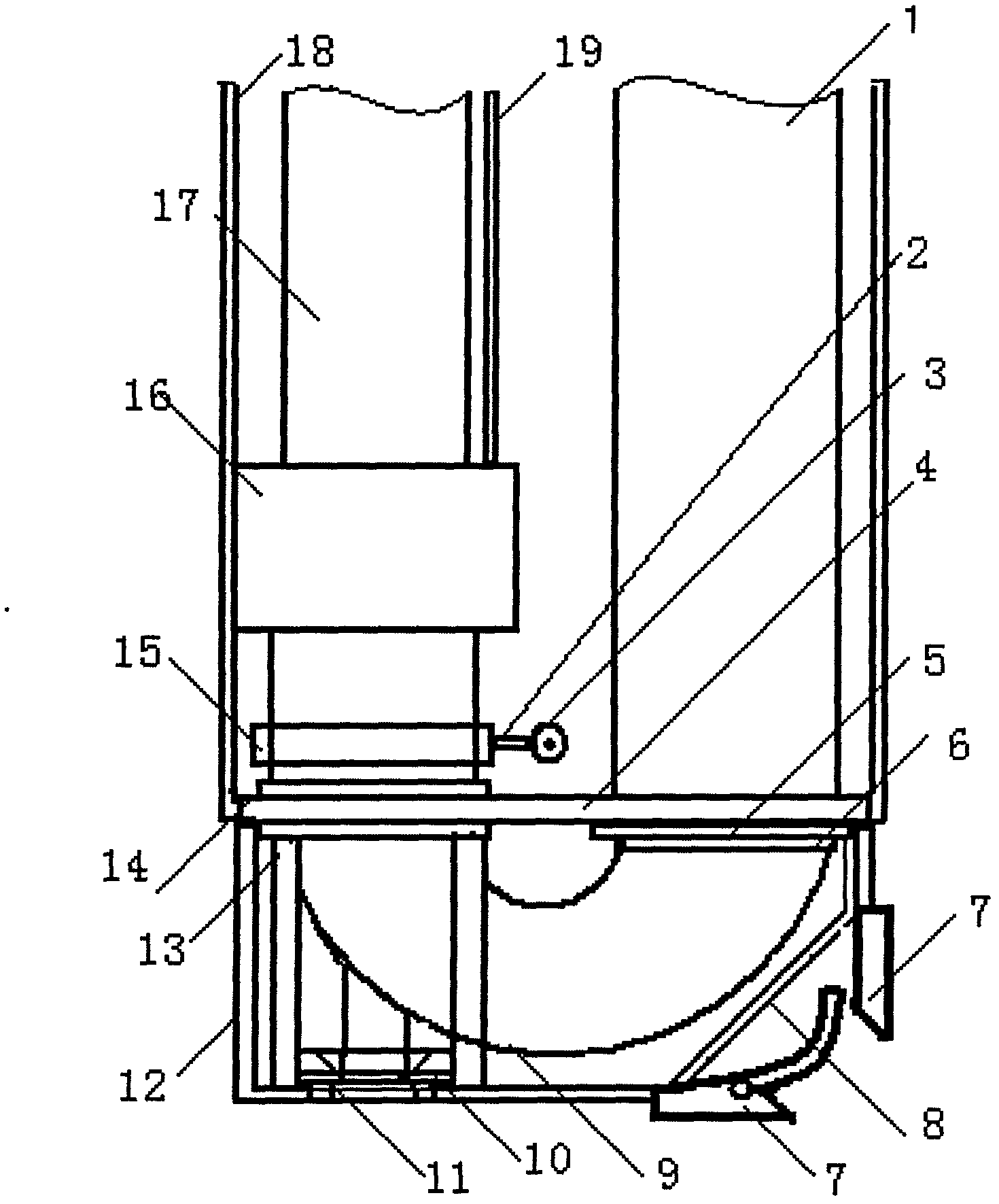

[0018] The embodiment is a two-cylinder suction device, which is used for suction and transportation of municipal sludge.

[0019] Municipal sludge is a kind of high liquid limit silty organic soil, which is neither solid nor liquid, and belongs to the category of Bingham body in plastic state. This kind of sludge is in a plastic state and flowing state. It has the characteristics of smelly, sticky, soft and black. It pollutes the air and pollutes the environment. In the past, there was no suitable sludge suction device, which has always been an urgent problem to be solved in the project.

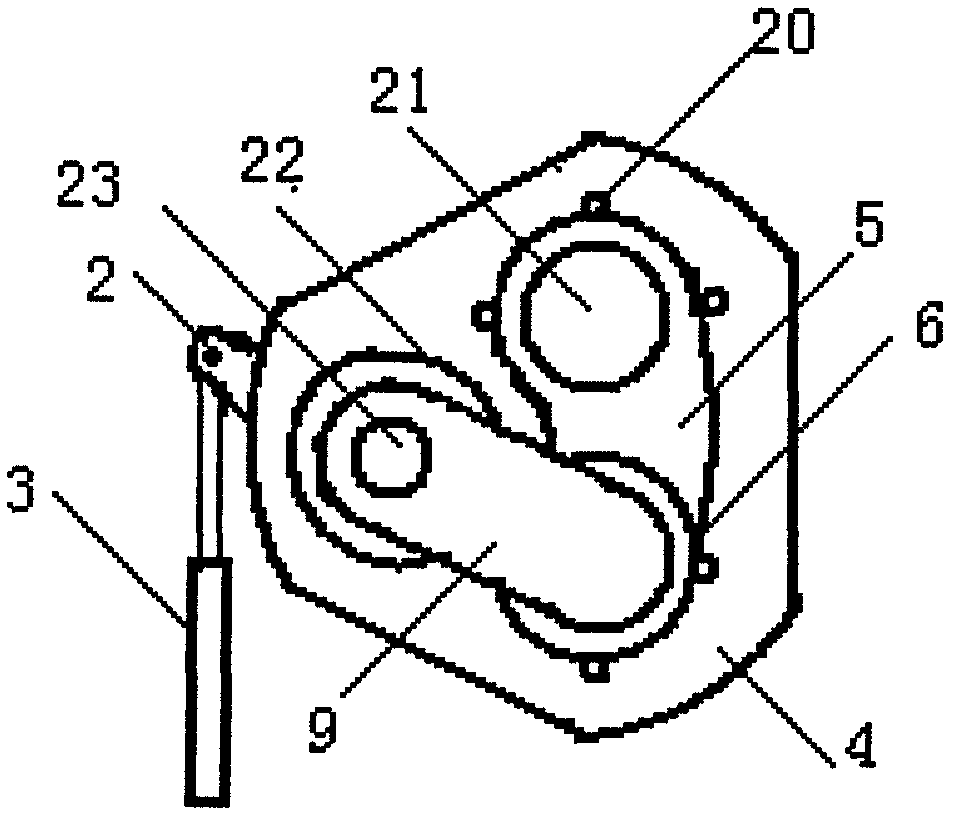

[0020] Such as figure 1 As shown, it includes working cylinder (1), reversing lever (2), reversing oil cylinder (3), cylinder head plate (4), wear plate (5), cutter ring (6), suction port (7) , film liquid ring nozzle (8), J-shaped tube (9), positioning bearing (10), spring leaf (11), sealing cover (12), positioning bracket (13), bearing bush (14), hoop ( 15), joint (16), feeding pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com