Suspension type cold crucible continuous melting and casting and directional solidification device

A technology of directional solidification and cold crucible, which is applied in crucible furnace, self-solidification method, crystal growth and other directions, can solve the problems of low superheat of alloy liquid and difficult directional control of solidification structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

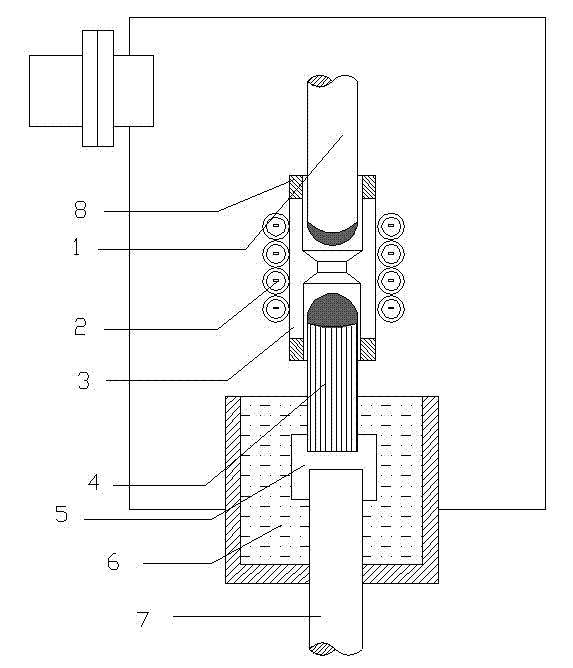

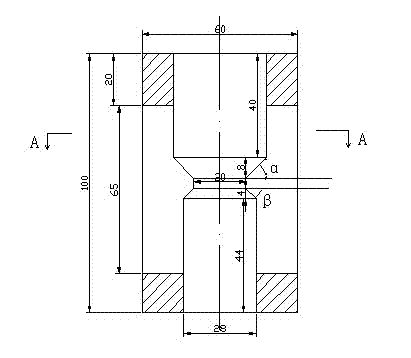

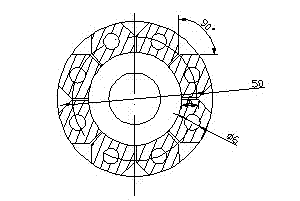

[0057] Suspended cold crucible continuous casting and directional solidification device, including closed furnace body, feeding rod, material rod, water-cooled copper crucible, induction coil, pull rod, crystallizer, coolant material, the upper end of the material rod in the furnace body is fixed On the lower end of the feeding rod, the lower end of the material rod extends into the water-cooled copper crucible, the water-cooled copper crucible has a slit structure, and an induction coil is wound outside the water-cooled copper crucible to excite the alternating magnetic field and diffuse into it through the slit In this way, the hot zone required for the processing process is generated. The crystallizer containing the coolant material is placed directly below the water-cooled copper crucible, and the drawing rod is placed in the crystallizer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com