Method for preparing reflection-reduction film element of light P with thickness of 193nm in large angle mode

A 1.193nm, thin-film component technology, applied in optical components, optics, sputtering coating, etc., can solve the problems of optical loss ArF excimer laser beam quality and output efficiency reduction, achieve wide angle tolerance and improve output efficiency , The effect of reducing the residual reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

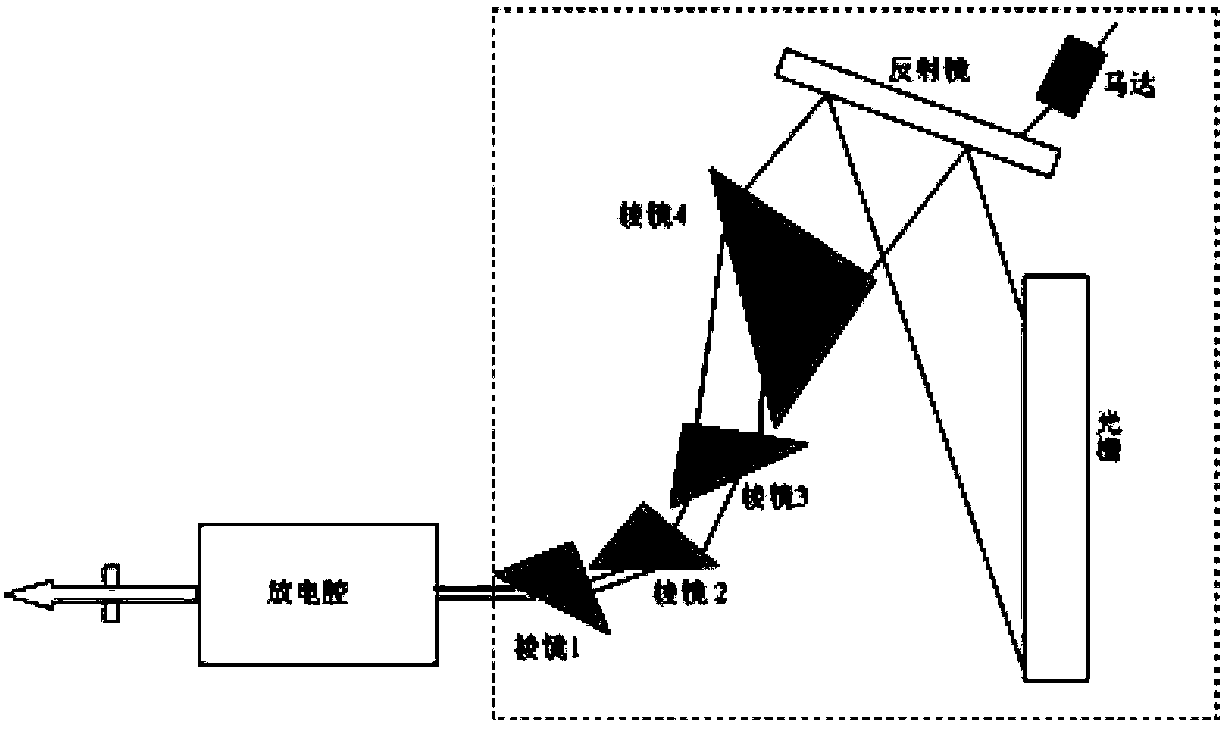

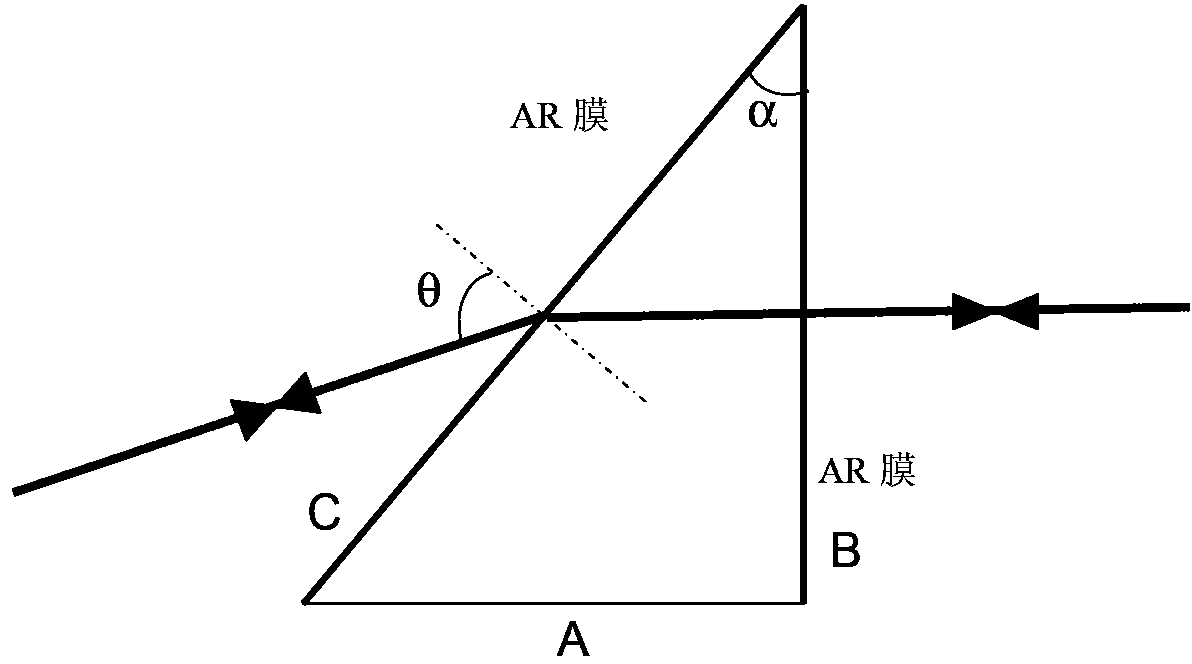

[0021] Specific implementation mode 1. Combination Figure 4 Describe this embodiment, the preparation method of 193nm P light large-angle anti-reflection film element, this method is realized by the following steps:

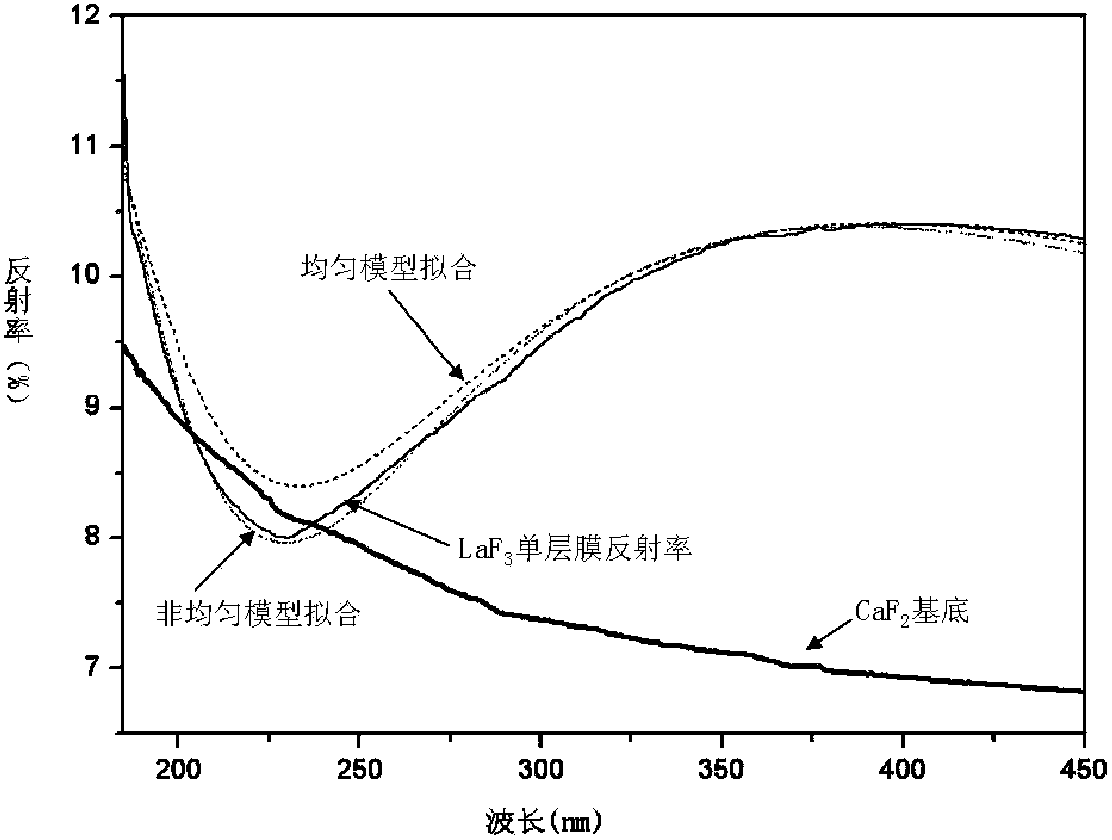

[0022] Step 1. Choose CaF 2 As the coating substrate, LaF was deposited on the substrate by vacuum thermal deposition method. 3 Monolayer and MgF 2 A single-layer film, the thicknesses of the two kinds of single-layer films are respectively 100 nm and 300 nm. and to LaF 3 Thin film layer and MgF 2 The optical constants of the film layer are analyzed, and the first-order non-uniformity model is used for the LaF3 film to obtain the LaF 3 The refractive index of the film layer at the 193nm working band is 1.68, the extinction coefficient is 0.0028, MgF 2 The refractive index of the film layer at the 193nm working band is 1.42, and the extinction coefficient is 0.00048;

[0023] Step 2, choose CaF in addition 2 As a coating substrate, multiple layers of MgF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com