Metal granular reinforced aluminum flux cored wire

A technology of flux-cored aluminum welding wire and metal particles, which is applied in metal processing equipment, welding medium, welding equipment, etc., can solve the problems of brittle welding wire, low weld strength, segregation, etc., to reduce the ductile-brittle transition temperature and improve the low temperature Impact toughness and crack resistance, effect of increasing weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

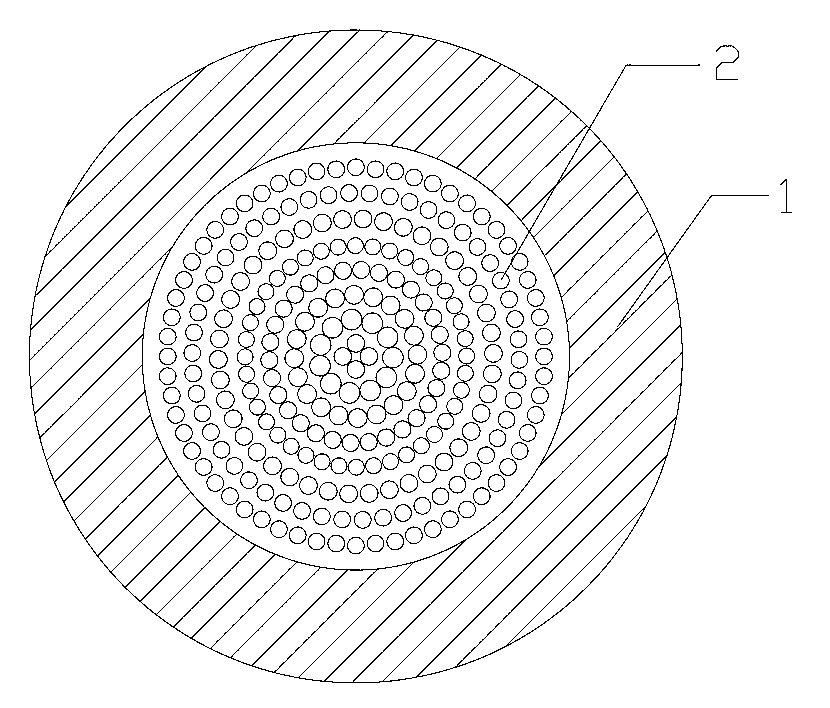

[0014] In the metal particle reinforced flux-cored aluminum welding wire of the present invention, the sheath 1 is an Al-9Si alloy, wherein the mass percentage of rare earth elements is 0.6%, and the flux core 2 accounts for 25% of the total mass of the aluminum welding wire.

[0015] Drug core 2 is made of raw materials potassium fluoroaluminate, K 3 BF 6 、K 2 SiF 6 , Cu-20Ni alloy, Al-22Si alloy, and Cu-20Si alloy are prepared according to the following mass percentage: 8% K 3 BF 6 , 10%K 2 SiF 6 , 2% Cu-20Ni alloy, 25% Al-22Si alloy, 20% Cu-20Si, and the balance is potassium fluoroaluminate.

[0016] Use a ball mill to grind the above raw materials to a particle size of 200 mesh powder and mix them evenly, sinter them in a vacuum furnace to form a sintered flux, and then use the vibration method to put the flux into an Al-9Si alloy tube with an outer diameter of 12mm and an inner diameter of 6mm, and roll it , rough drawing, annealing, fine drawing, layer winding and...

Embodiment 2

[0019] In the metal particle reinforced flux-cored aluminum welding wire of the present invention, the sheath 1 is an Al-9.5Si alloy, wherein the mass percentage of rare earth elements is 0.4%, and the flux core 2 accounts for 30% of the total mass of the aluminum welding wire.

[0020] Drug core 2 is made of raw materials potassium fluoroaluminate, K 3 BF 6 、K 2 SiF 6 , Cu-10Ni alloy, Al-20Si alloy, and Cu-40Si alloy are formulated according to the following mass percentages: 15% K 3 BF 6 , 17%K 2 SiF 6 , 6% Cu-10Ni alloy, 10% Al-20Si alloy, 7% Cu-40Si alloy, and the balance is potassium fluoroaluminate.

[0021] The manufacturing method of welding wire is the same as embodiment 1.

[0022] The flux-cored aluminum wire and common Al-12Si / potassium fluoroaluminate flux-cored wire were used to conduct a brazing comparison test on 6063 aluminum alloy. The result shows: weld component analysis shows that Si content in the weld seam of flux-cored welding wire of the presen...

Embodiment 3

[0024] In the metal particle reinforced flux-cored aluminum welding wire of the present invention, the sheath 1 is an Al-9Si alloy, wherein the mass percentage of rare earth elements is 0.6%, and the flux core 2 accounts for 25% of the total mass of the aluminum welding wire.

[0025] Drug core 2 is made of raw materials potassium fluoroaluminate, K 3 BF 6 、K 2 SiF 6 , Cu-2Ni alloy, and Al-22Si alloy are formulated according to the following mass percentages: 5% K 3 BF 6 , 35%K 2 SiF 6 , 10% Cu-2Ni alloy, 20% Al-22Si alloy, and the balance is potassium fluoroaluminate.

[0026] The manufacturing method of welding wire is the same as embodiment 1.

[0027] The advantage of welding wire of the present invention is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com