A kind of vacuum brazing paste solder without flux, preparation method and application method thereof

A technology of brazing paste and brazing material, which is applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problems of electrochemical corrosion of welding joints, inability to completely discharge brazing flux, and reduce the performance of welding joints, etc., to achieve Strong applicability, suitable for automatic production, and the effect of saving solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

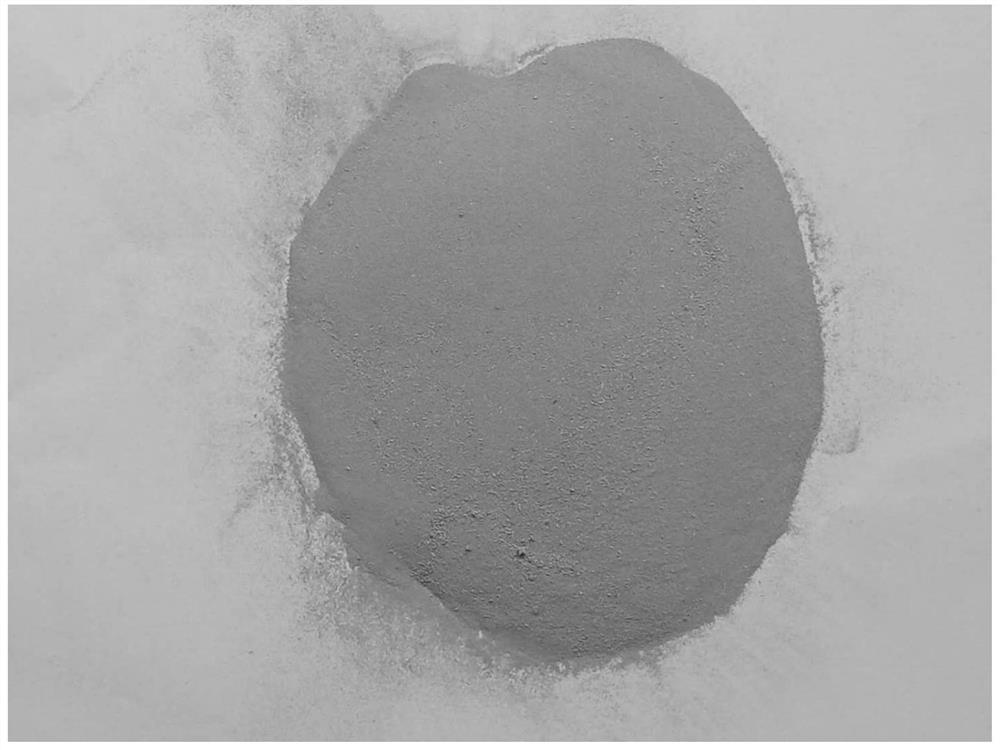

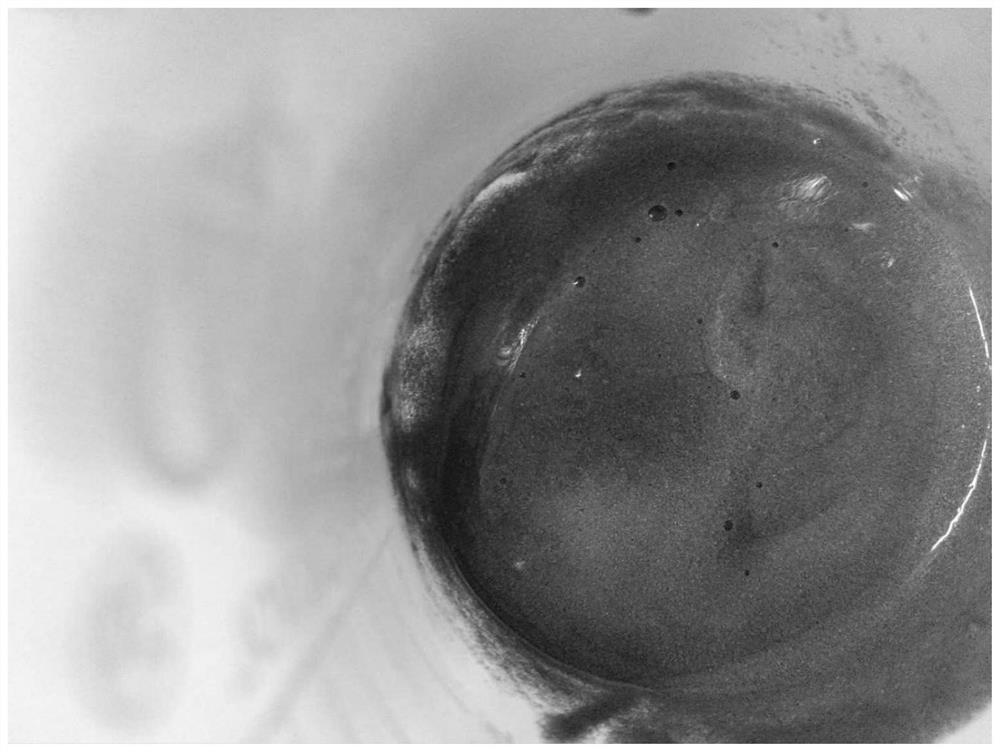

[0035] Specific embodiment one: the present embodiment does not contain brazing flux and the vacuum brazing paste solder is composed of 45% to 60% solder alloy powder and 40% to 55% binder according to the mass fraction; the paste solder No brazing flux is contained in the material; the brazing alloy powder is prepared from 6% to 10% Mg, 15% to 20% Cu and 70% to 75% Al according to the mass fraction; the binder is prepared from It consists of 75%-85% hexanediol, 8%-12% rosin resin, 2%-6% n-decyl alcohol and 1.5%-4% glycerin; the particle size of the solder alloy powder is less than 49 μm.

specific Embodiment approach 2

[0036] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that transition group elements are also added to the vacuum brazing paste solder without flux, and the addition amount of the transition group elements is 0.1%. ~3.5%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037]Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the transition group element is Ti. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com