Active aluminum detection method

A measurement method, the technology of active aluminum, which is applied in the direction of analyzing the material by chemical reaction and analyzing the material by observing the influence on the chemical indicator, which can solve the problems of strict operation requirements, harsh conditions and high cost, and achieve the test The effect of high precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0044] Let me introduce the instruments needed in this embodiment as follows:

[0045] Separating funnel: 250 ml, 2 pieces

[0046] Burette: 50 ml, 1 piece

[0047] Erlenmeyer flask with ground mouth: 500 ml, 2 pcs

[0048]The above description is not intended to limit the instrument used in the present invention to the above content and cannot be replaced. In fact, in the present invention, any instrument that can achieve the functions of the above instrument can be used as the instrument of the present invention.

[0049] The reagent used in the invention is as follows:

[0050] 1% (mass volume ratio: 1 gram of sodium diphenylamine sulfonate dissolved in 100 ml of water) sodium diphenylamine sulfonate indicator.

[0051] Sulphur-phosphorus mixed acid: 98% sulfuric acid and 85% phosphoric acid are mixed at a volume ratio of 1:4.

[0052] 15% NaHCO3 saturated solution: 15 grams of NaHCO3 dissolved in 100ml of water.

[0053] 10% sulfuric acid aqueous solution: Measure 10m...

example 1

[0057] In the following implementation, the sample is 0.15 grams as the criterion, to introduce the specific implementation process of the method, a method for the determination of active aluminum, comprising the steps:

[0058] Step 1, prepare Fe 2 (SO 4 ) 3 Reagent; Concrete process is as follows: take by weighing 330 grams of Fe 2 (SO 4 ) 3 In 750 ml of water, add 75 ml of 98% concentrated sulfuric acid, heat to dissolve, dilute into 1000ml volumetric flask after cooling.

[0059] Step 2, weighing and dissolving the sample: the specific process is as follows: Accurately weigh a certain amount (such as but not limited to 0.15 g) of aluminum powder sample into a 500 ml ground-mouth conical flask, and slowly add 25 to 35 m1 (preferably 30 m1) Fe 2 (SO 4 ) 3 solution; Immediately plug the bottle with a rubber stopper equipped with a separatory funnel and an outlet hose, and insert one end of the outlet tube into a solution filled with saturated NaHCO 3 solution in the...

Embodiment 2

[0069] The only difference between Example 2 and Example 1 is that in step 3, before adding the sodium diphenylamine sulfonate indicator, 15 ml of sulfur-phosphoric acid and about 30 ml of water are added. There are two effects of adding sulfur-phosphorus mixed acid: one is to control the acidity required for titration; the other is to make the color change of the indicator more sensitive; it can make the determination more accurate.

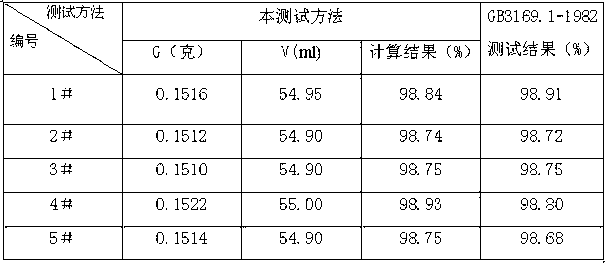

[0070] Table 1 is a set of data of the parallel test of the method involved in the patent of the present invention and the national standard active aluminum detection method (GB3169.1-1982). The results show that the measurement results of the method of the present invention are within the tolerance range (parallel ≤ 0.8%), Fully able to meet the requirements, and convenient and easy.

[0071]

[0072] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com