Method and device for ultraviolet optic online automatic detection of indium tin oxide (ITO) membrane circuit pattern defect information

A thin-film circuit and circuit pattern technology, applied in the field of ultraviolet optical online automatic detection, can solve the problems of high labor intensity, low grayscale contrast, high missed detection rate, and achieve enhanced reliability and accuracy, stable detection results, and detection speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

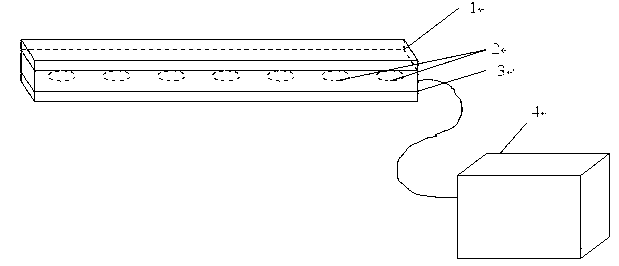

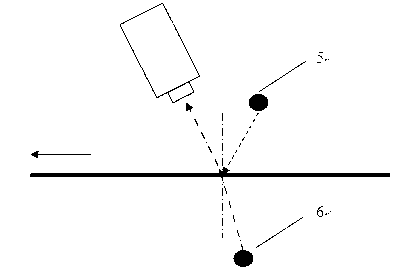

[0032] Embodiments of the present invention refer to Figure 1-6 .

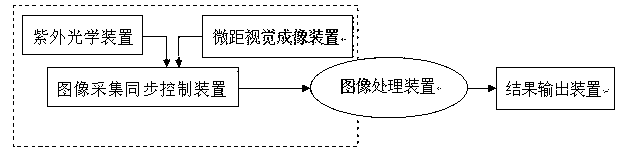

[0033] Such as figure 1 As shown, the detection device of the present invention includes an ultraviolet optical device, a macro vision imaging device, an image acquisition synchronization control device, an image processing device and a result output device. Connect each device in order and work together. The steps are as follows: After the detection device is started, the user starts image acquisition through the human-computer interaction device. At this time, the ultraviolet optical device enters the working state, and the imaging resolution is preset according to the specific detection requirements. The high-efficiency macro imaging device provides appropriate lighting, and the encoder connected to the ITO film coaxially outputs the original synchronous signal, which is converted and processed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com