Non-destructive testing systems and method used for detecting a metal-containing object through X-ray detection

A technology of X-rays and metal ropes, which is applied in the field of machine vision, can solve problems such as limitations, and achieve the effects of improving life expectancy, increasing safe working time, and improving industry safety levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

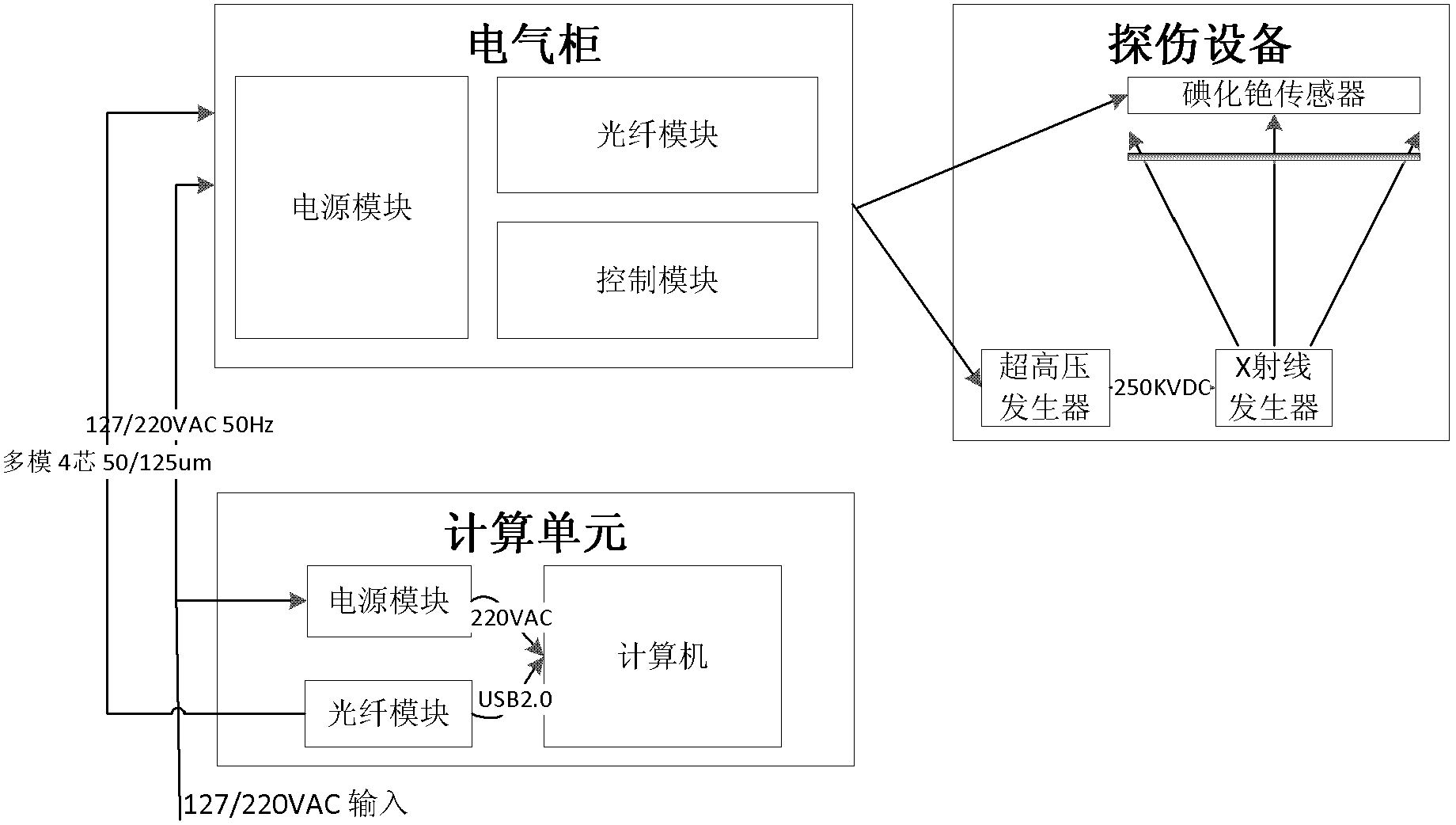

[0037] figure 1 It is a structural diagram of the non-destructive testing system for a target containing a metal rope provided by the present invention. The target containing a metal can be, for example, a steel wire rope belt. The technical solution of the present invention is described.

[0038] Such as figure 1 Shown, according to one aspect of the present invention, provide a kind of system that carries out non-destructive detection to the measured object that contains metal rope by X-ray, this system comprises: ultra-high voltage (250kv) generator, X-ray generator, cesium iodide (CsI) sensors, fiber optic modules, control modules, computers and power modules, of which:

[0039] The ultra-high voltage generator is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com