Production method for conductors for fire-resistant middle-high voltage cables

A technology for medium and high voltage cables and a manufacturing method, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of not being able to save time for rescue work, the structure is too simple, and the heat insulation effect is poor, and the mechanical strength is achieved. Good, good bending performance, rounded shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

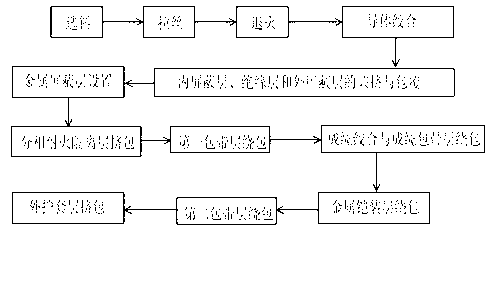

[0032]A conductor manufacturing method for fire-resistant medium and high voltage cables, comprising the following steps: material selection → wire drawing → annealing → conductor stranding → co-extrusion and cladding of inner shielding layer, insulating layer and outer shielding layer → metal shielding layer setting → Extrusion of phase-separated refractory isolation layer → first tape layer wrapping → cable twisting and cabled tape layer wrapping → metal armor layer wrapping → second tape layer wrapping → outer sheath layer extrusion The step of extruding the phase-separated refractory isolation layer refers to extruding the vitrified silicone rubber material on the metal shielding layer with a silicone rubber extruder, with a thickness of 2.0 mm.

[0033] In the present invention, the conductor stranding step refers to stranding the multiple strands of tinned copper monofilaments formed after the wire drawing process into a conductor according to the stranding pitch being 10...

Embodiment 2

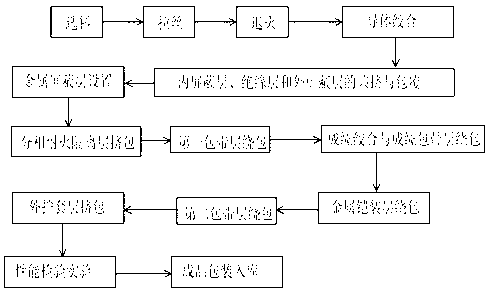

[0041] A conductor manufacturing method for fire-resistant medium and high voltage cables, comprising the following steps: material selection → wire drawing → annealing → conductor stranding → co-extrusion and cladding of inner shielding layer, insulating layer and outer shielding layer → metal shielding layer setting → Extrusion of phase-separated refractory isolation layer → first tape layer wrapping → cable twisting and cabled tape layer wrapping → metal armor layer wrapping → second tape layer wrapping → outer sheath layer extrusion →Performance inspection experiment→The finished product is packaged and stored in the warehouse. The step of extruding the phase-separated refractory isolation layer refers to extruding the vitrified silicone rubber material on the metal shielding layer with a silicone rubber extruder, and the extruded thickness is 3.0mm.

[0042] In the present invention, the conductor stranding step refers to stranding the multi-strand tinned copper monofilame...

Embodiment 3

[0052] A conductor manufacturing method for fire-resistant medium and high voltage cables, comprising the following steps: material selection → wire drawing → annealing → conductor stranding → co-extrusion and cladding of inner shielding layer, insulating layer and outer shielding layer → metal shielding layer setting → Extrusion of phase-separated refractory isolation layer → first tape layer wrapping → cable twisting and cabled tape layer wrapping → metal armor layer wrapping → second tape layer wrapping → outer sheath layer extrusion →Performance inspection experiment→The finished product is packaged into the warehouse. The step of extruding the phase-separated refractory isolation layer refers to extruding the vitrified silicone rubber material on the metal shielding layer with a silicone rubber extruder, with a thickness of 4.0mm.

[0053] In the present invention, the conductor stranding step refers to stranding the multi-strand tinned copper monofilaments formed after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com