High-sensitivity mass spectrum ionization source for analyzing explosive online and application thereof

A technology for ionization sources and explosives, applied in the field of analytical instruments, can solve the problems of difficult to obtain sample signals, difficult detection of explosives, small air intake, etc., and achieve the effect of fast and high-sensitivity inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

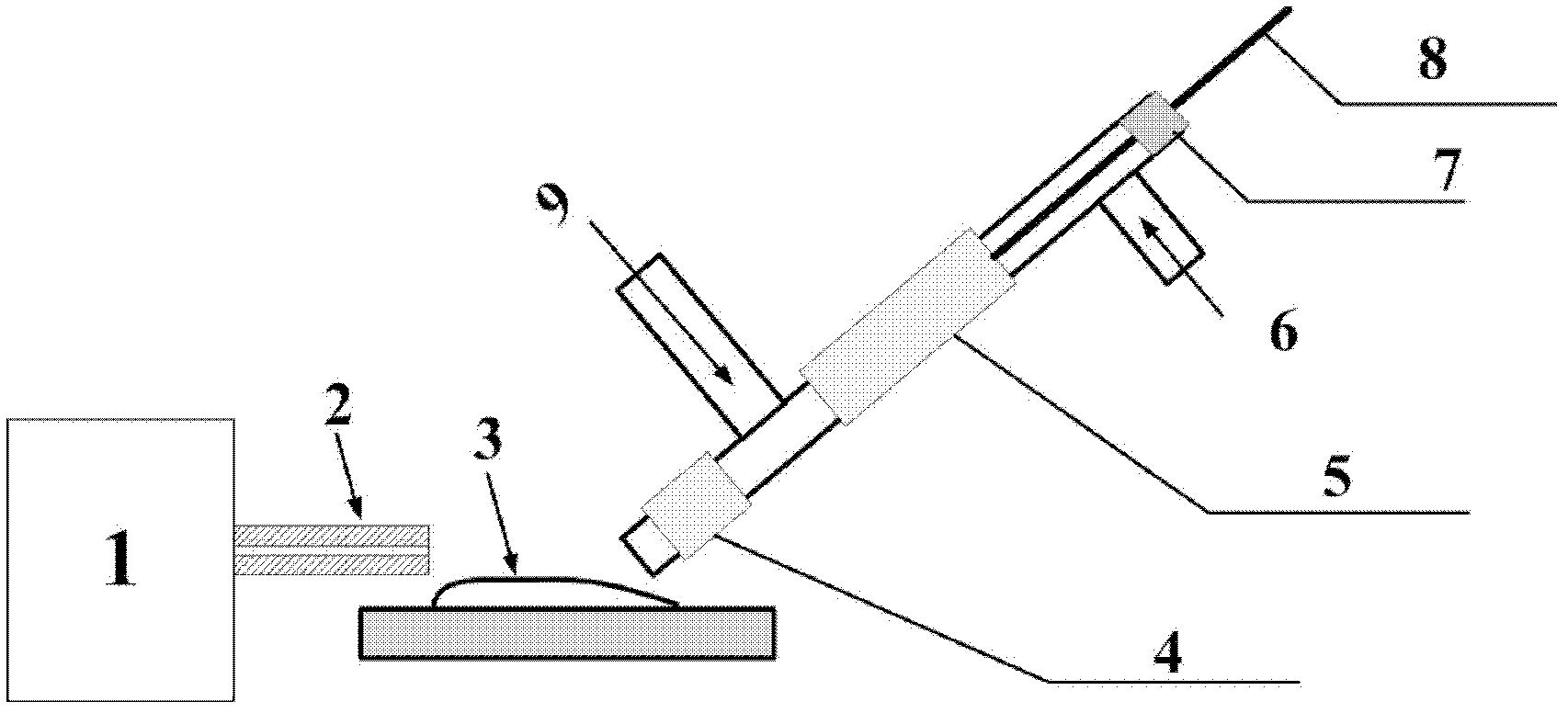

Method used

Image

Examples

Embodiment 1

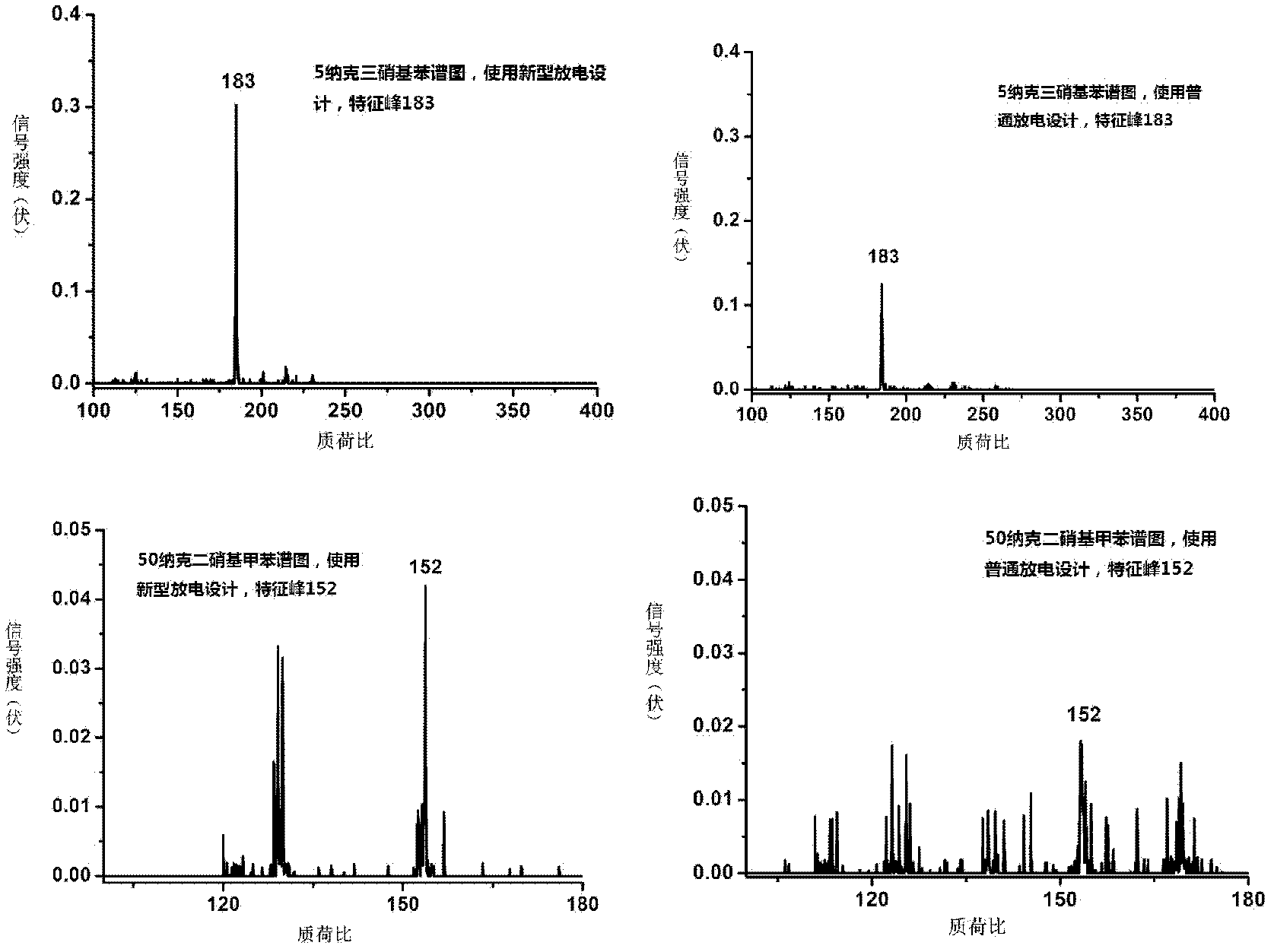

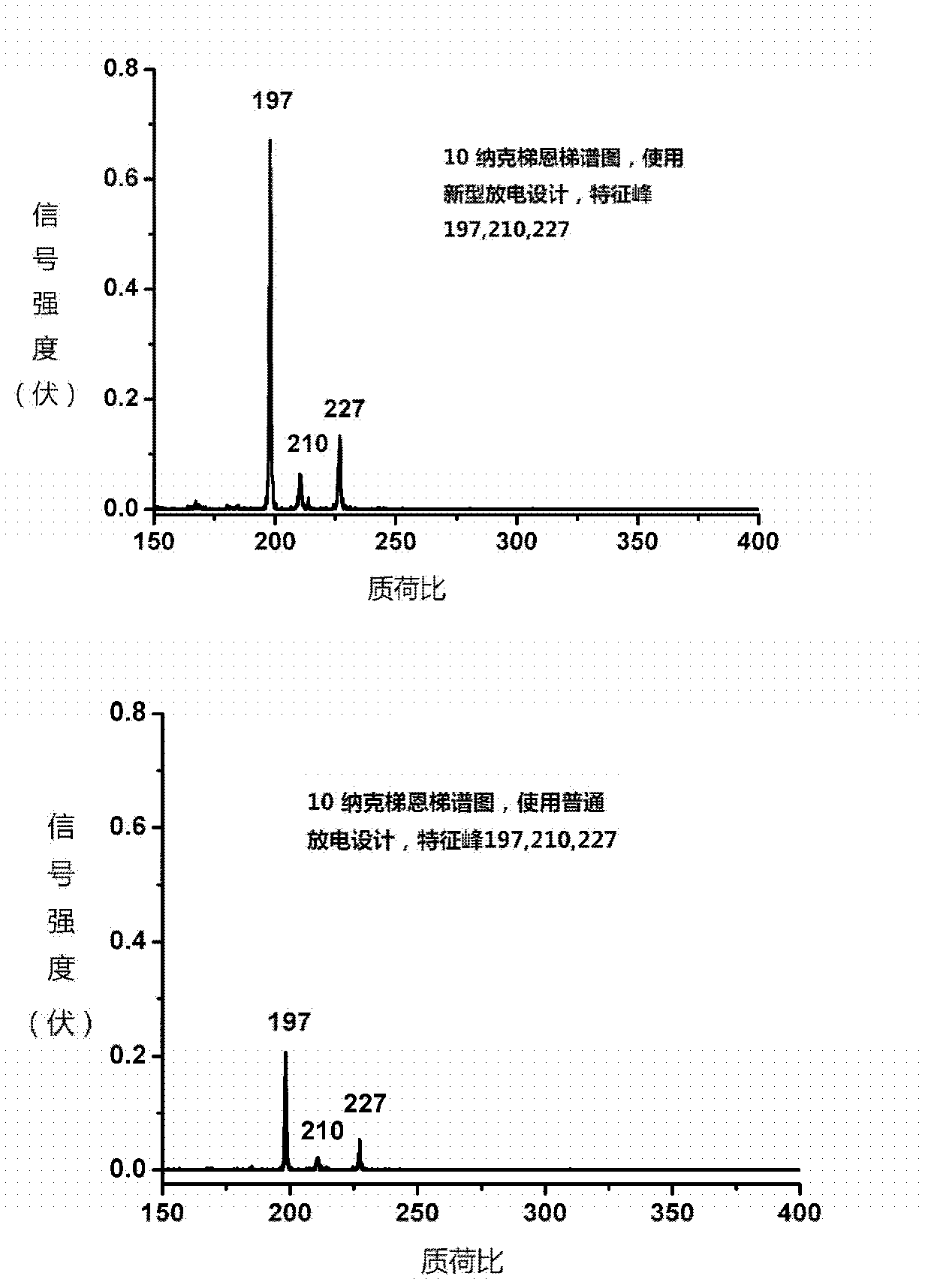

[0031] When the ionization source is used in conjunction with an online mass spectrometer, the sample is placed on the surface of a glass slide, and 1 microliter of sample is dropped on the glass slide using a sampling gun. Placed 2mm above the glass slide. The flow rate of the discharge gas helium is 1.2L / min, the discharge voltage is 6kV, and the frequency of the high-voltage radio frequency power supply is 31kHz. The analysis time is 3s, 5ng 1,3,5 trinitrobenzene uses this ionization source to analyze the signal as figure 2 As shown, the signal intensity is 3 times higher than that of the common discharge ionization source, the signal intensity of TNT is 5 times higher, and the signal of dinitrotoluene is also 3 times higher. When the conditions are optimized, 0.25ng can be detected for TNT, and its spectrum is as follows image 3 shown. The three samples used, 1, 3, 5 trinitrobenzene, TNT and dinitrotoluene, the obtained sample spectra are simple and there are no redun...

Embodiment 2

[0033]In a common discharge ionization source, since there is only one discharge area, the heat generated by the discharge is relatively small, and the compounds with poor volatility cannot be effectively ionized, and the signal of the sample cannot be obtained. Since the new ionization source introduces the second discharge area, the discharged helium can carry heat more effectively to desorb the explosives on the surface of the object, so the signal of the non-volatile explosives can be obtained smoothly. When the ionization source is used in conjunction with an online mass spectrometer, the sample is placed on the surface of a glass slide, and 1 microliter of sample is dropped on the glass slide using a sampling gun. Placed 2mm above the glass slide. The flow rate of the discharge gas helium is 1.2L / min, the discharge voltage is 6kV, and the frequency of the high-voltage radio frequency power supply is 31kHz. 5ng samples of TNT, RDX and Tequel were placed on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com