Methods for gasification of carbonaceous materials

A carbonaceous material and carbonaceous technology, applied in the field of carbonaceous material gasification, can solve the problems of increasing the difficulty and cost of disposing ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-29

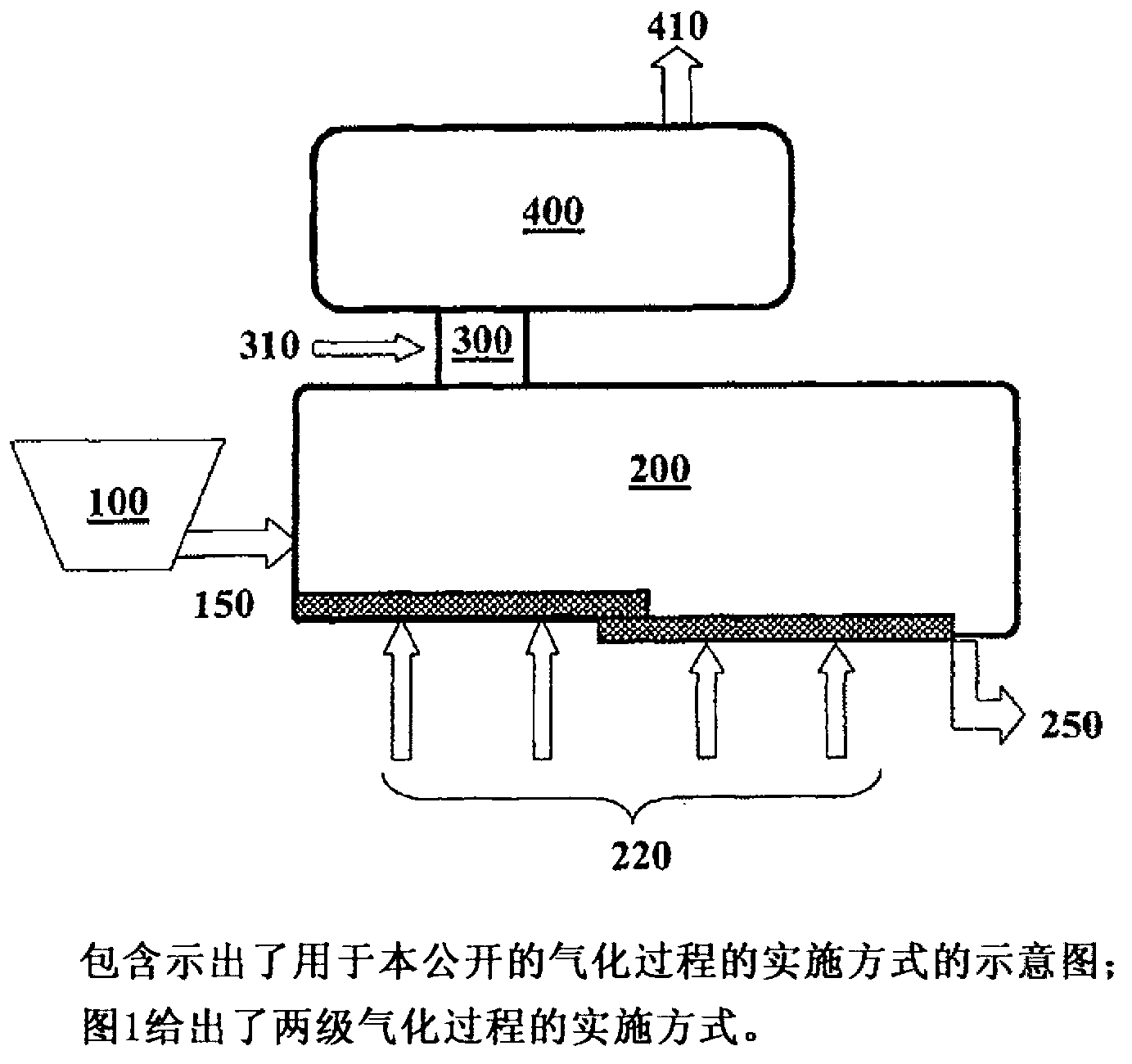

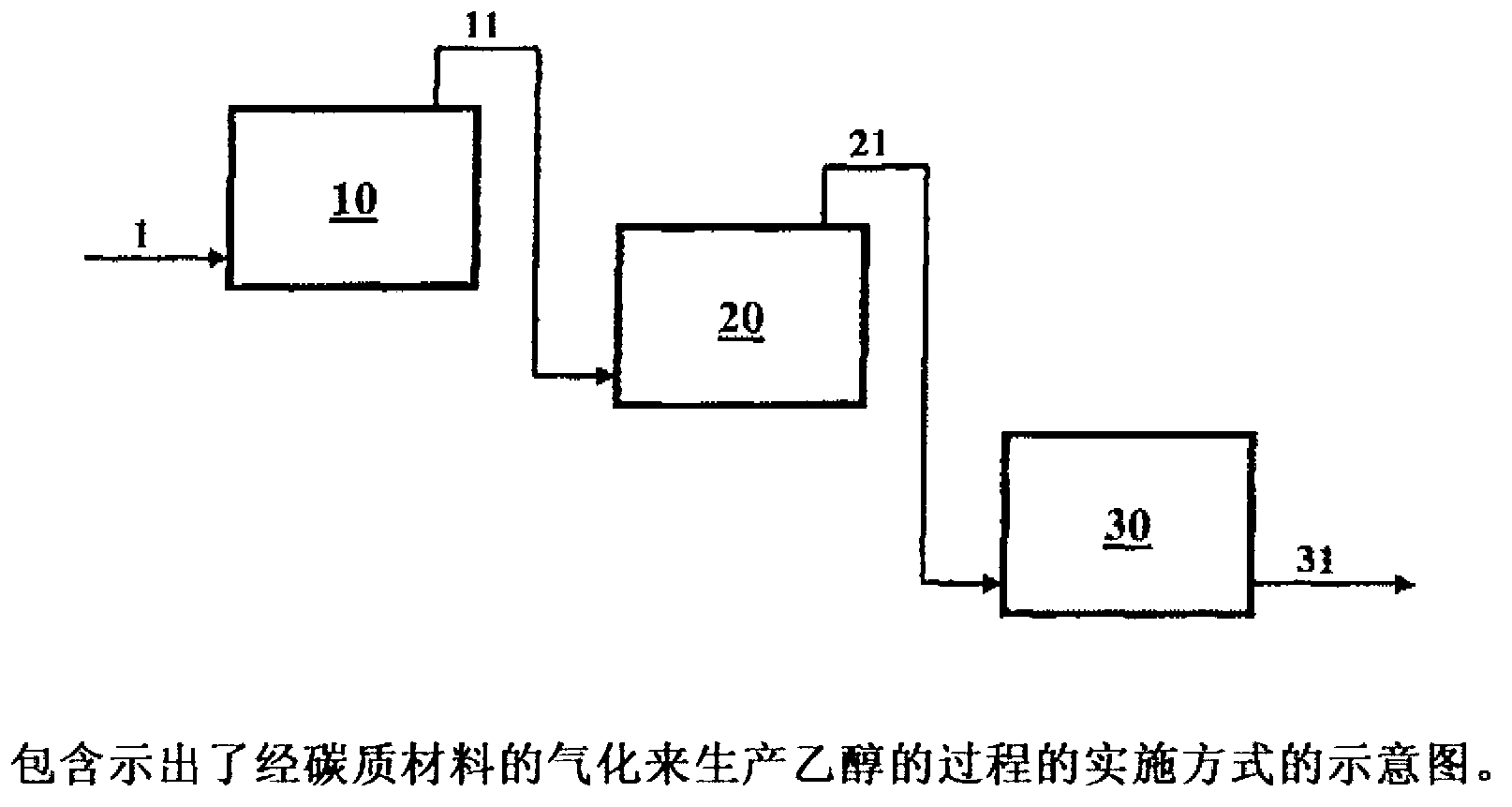

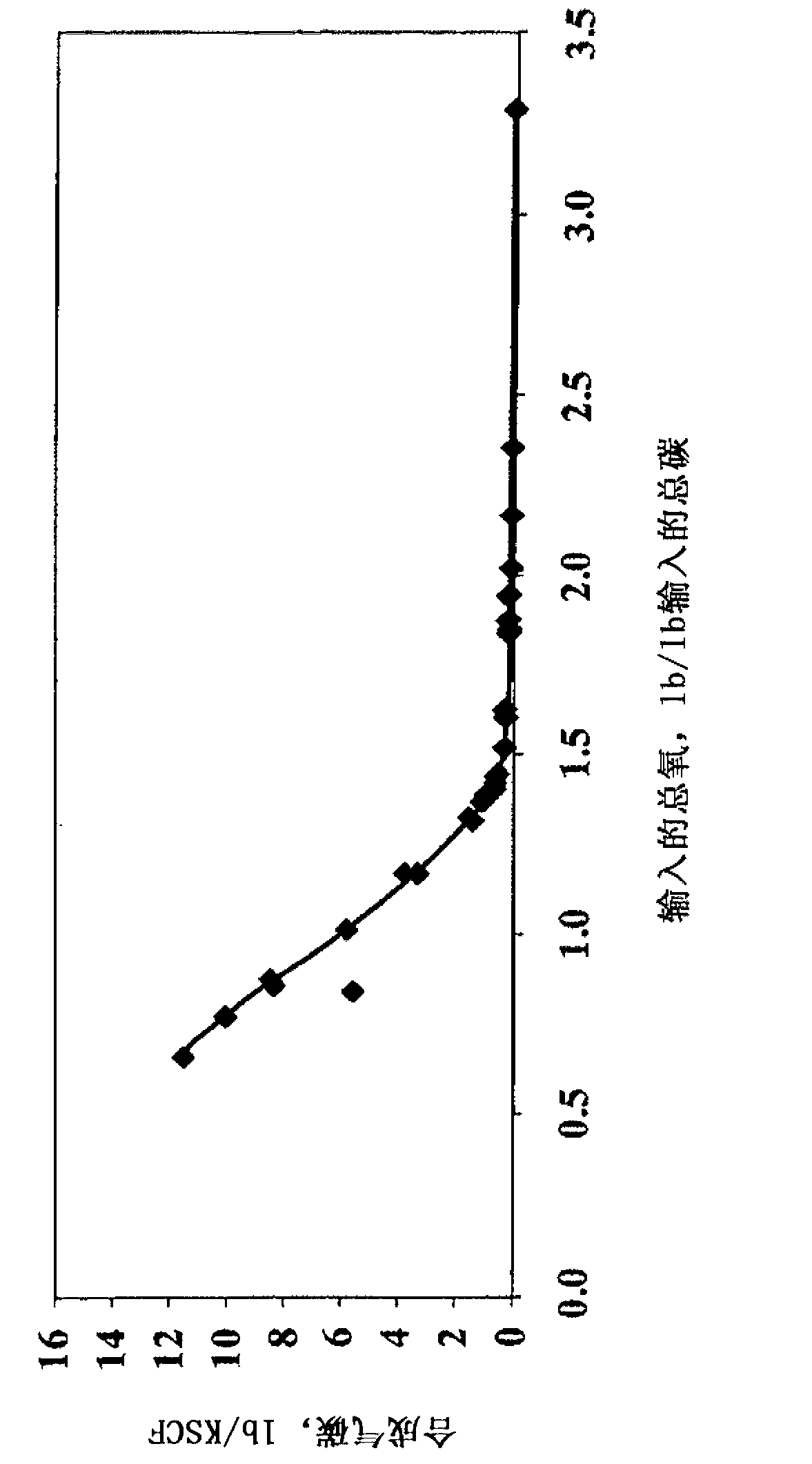

[0112] Examples 1-29 illustrate embodiments for gasifying carbonaceous materials when the carbonaceous materials contain no or negligible water and no direct addition of water or steam to the gasifier, and where the carbonaceous materials Embodiments of gasifying carbonaceous materials with large amounts of water and / or direct addition of large amounts of water or steam to the gasifier. These examples illustrate the gasification of single carbonaceous materials such as coal, coke oven tar (coke), plastics, tires, wood, polystyrene (PS), polyethylene terephthalate (PETA). Embodiments, and gasification of various carbonaceous materials such as blends of tires and wood, blends of plastics and wood, blends of plastics and msw, and blends of coke oven tar and fiber soft implementation. For all of these examples, the temperature in the first reaction zone was 1400°F and the temperature in the second reaction zone was 2250°F. The relevant carbonaceous material properties, other gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com