Shaking machine for biochemical test and shaking method of shaking machine

A technology for testing and shaking machines, which is applied in the field of shaking machines, can solve the problems of inapplicability to a variety of different phases to be shaken, single shaking method, and inaccurate proportioning, and achieve great commercial value and experimental results. Precise structure and good shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

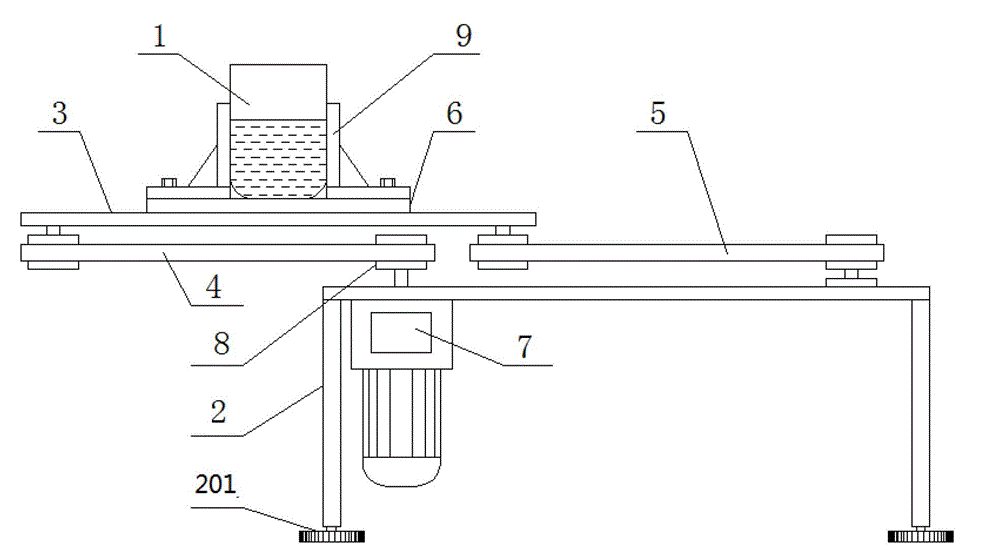

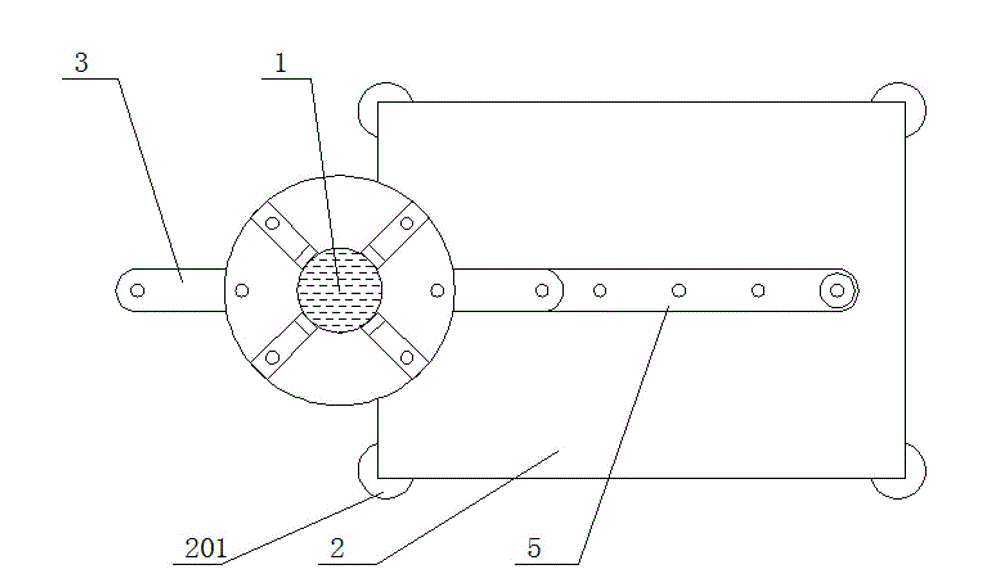

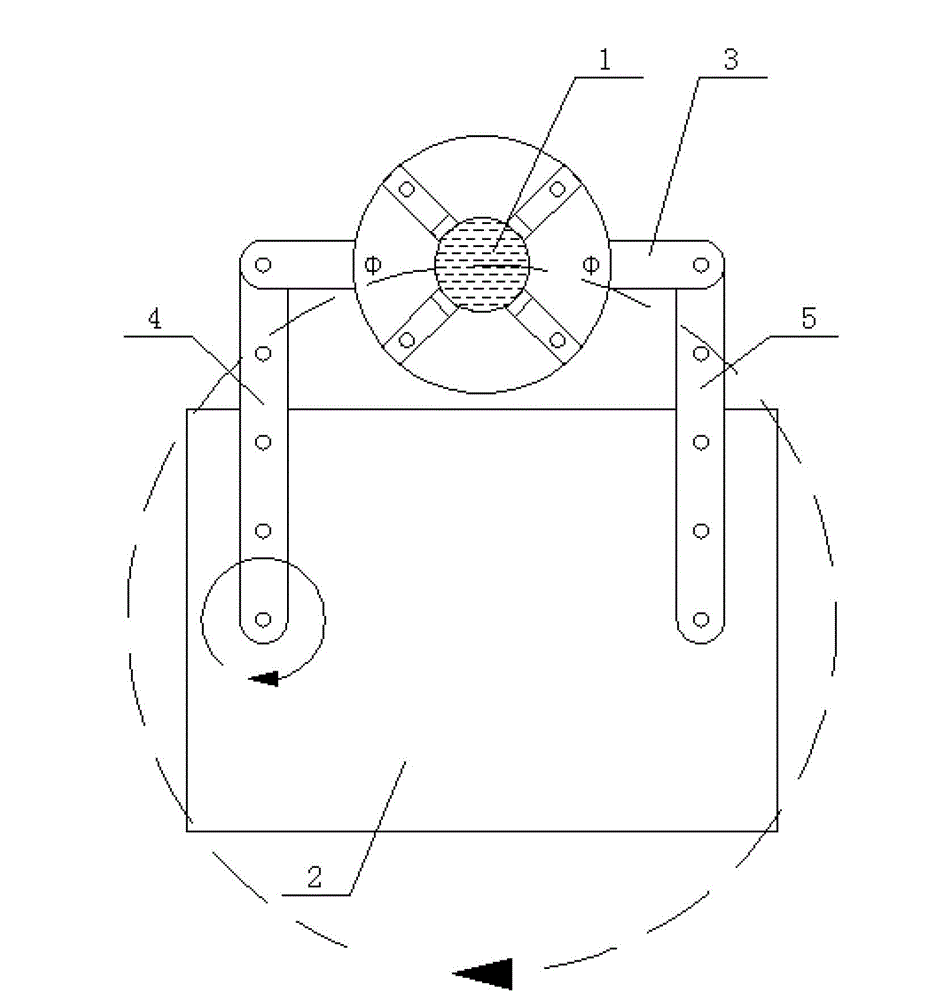

[0037] In the biological fermentation experiment, the water and the lactic acid bacteria liquid are mixed according to the ratio of 100:1. Since the bacteria liquid and the water are both in liquid state and are relatively easy to mix, a circular motion with a small centrifugal force is sufficient. see Figure 4 , the two ends of the connecting rod 3 are respectively connected to the crank 4 and the rocker 5, the radius of rotation is selected to be the smallest, and the radius of rotation of the crank 4 and the rocker 5 is the same, combined figure 1 , Figure 4 , the tray 6 and the container 1 are installed on the connecting rod 3 . Due to the small centrifugal force and differential speed generated when the radius is small, the water and alcohol are mixed evenly after 5 minutes.

Embodiment ( 2

[0039] In the detection of feed crude protein, it is necessary to mix water and sodium hydroxide according to the ratio of 100:40. Since water is liquid and potassium chloride is solid, the shaking range required for dissolution is relatively large, so a large centrifugal force is required. circular motion. The installation method is as follows image 3 As shown, the two ends of the connecting rod 3 are respectively connected to the crank 4 and the rocker 5, the radius of rotation is selected to be the largest, and the radius of rotation of the crank 4 and the rocker 5 is the same, and the tray 6 and the container 1 are installed on the connecting rod 3 . Due to the large centrifugal force and differential speed generated when the radius is large, the water and potassium chloride are evenly mixed after 10 minutes.

Embodiment ( 3

[0041] In the flocculation experiment, the polyacrylamide and water were mixed according to the ratio of 3:100. Since the polyacrylamide was partially dissolved, the solution was viscous. A horizontal one-way shaking method is required, that is, the inertia of the solute and solution movement is used to generate a differential speed to accelerate the dissolution. The installation method is as follows Figure 5 As shown, the two ends of the connecting rod 3 are respectively connected to the crank 4 and the rocking bar 5, the radius of rotation of the crank 4 is selected to be the smallest, the radius of rotation of the rocking bar 5 is larger than that of the crank 4, and the tray 6 and the container 1 are placed on the top of the rocking bar 5. During operation, the crank 4 moves in a circle, and the rocker 5 moves back and forth along the arc track. The arc shaking of the rocker 5 during operation will cause the solvent and the solute to produce an inertia differential, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com