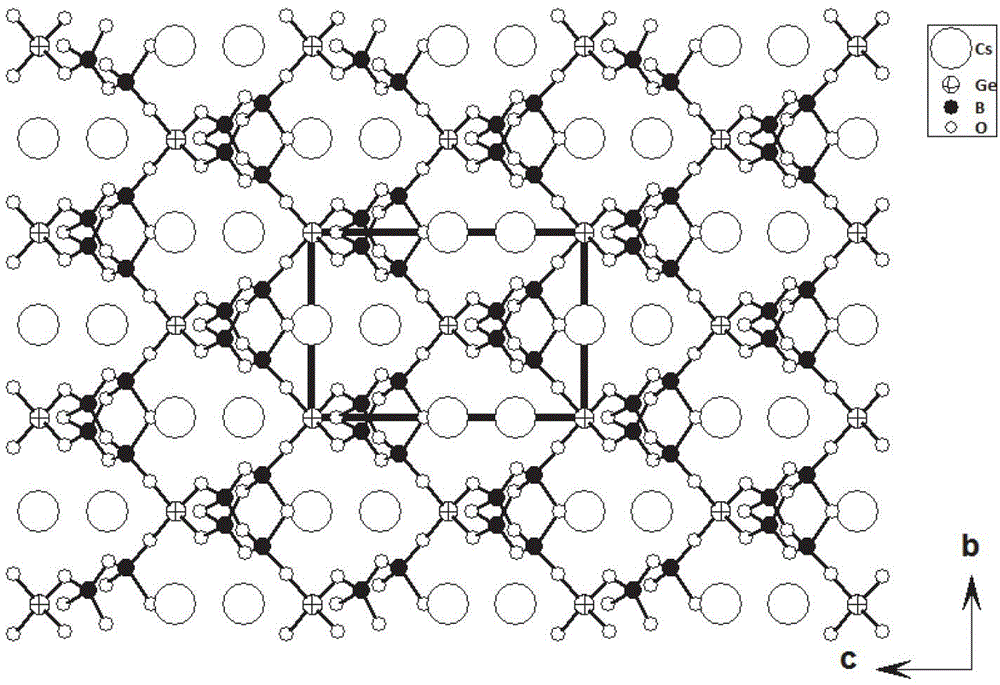

Cs2GeB4O9 compound and single crystal thereof

A compound, single crystal technology, applied in the field of new nonlinear optical crystal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

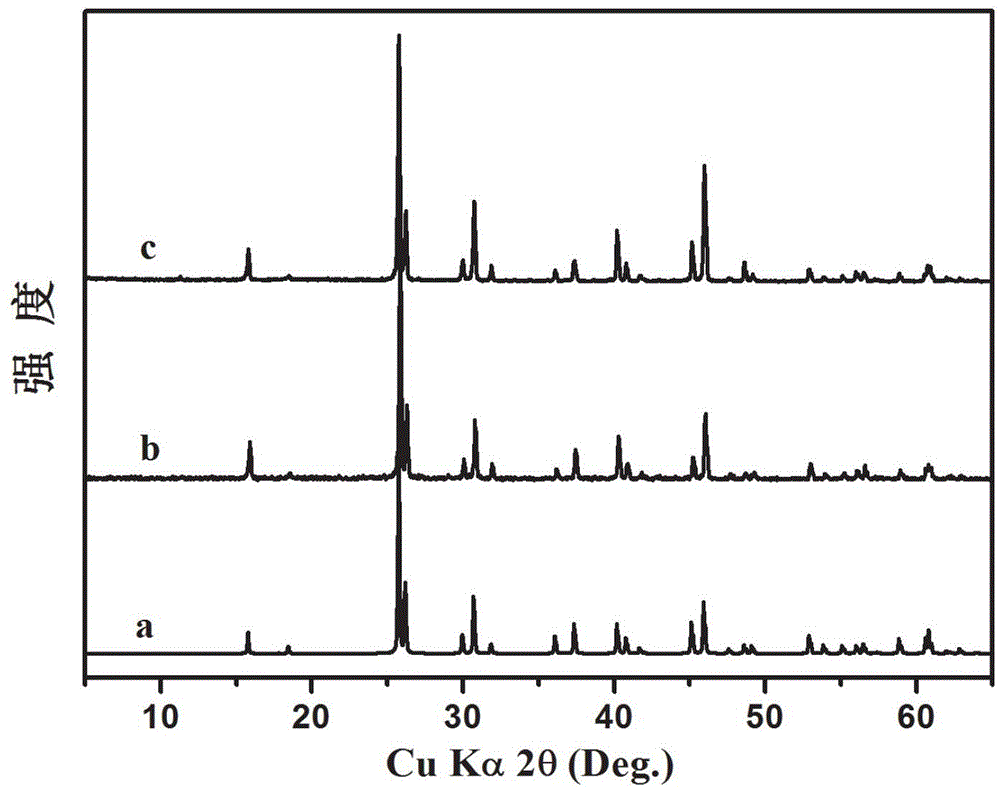

[0025] Synthesis of Compound Cs by High Temperature Solid Phase Synthesis 2 GeB 4 o 9

[0026] Raw materials used: Cs 2 CO 3 3.258g (0.01mol)

[0027] GeO 2 1.046g (0.01mol)

[0028] B 2 o 3 1.392 g, (0.02 mol)

[0029] Its chemical reaction equation is:

[0030] Cs 2 CO 3 + GeO 2 + 2B 2 o 3 = Cs 2 GeB 4 o 9 + CO 2 ↑

[0031] The specific operation steps are as follows: after the above-mentioned raw materials are weighed according to the above-mentioned dosage, they are carefully ground in a mortar, mixed evenly, put into a platinum crucible, put into a muffle furnace, heated to 600°C, and pre-fired at a constant temperature for 5 hours. Then take out the crucible after cooling, pour out the sample, re-grind evenly, put it into the platinum crucible again, sinter in the muffle furnace at 800°C for 50 hours, and turn off the power of the muffle furnace. After cooling, take out the crucible to get a lumpy white sample, which is the com...

Embodiment 2

[0033] Synthesis of Compound Cs by High Temperature Solid Phase Synthesis 2 GeB 4 o 9

[0034] Raw materials used: Cs 2 CO 3 3.258g (0.01mol)

[0035] GeO 2 1.046g (0.01mol)

[0036] HBO 3 2.473 g, (0.04 mol)

[0037] Its chemical reaction equation is:

[0038] Cs 2 CO 3 + GeO 2 + 4H 3 BO 3 = Cs 2 GeB 4 o 9 + CO 2 ↑+6H 2 O↑

[0039] The specific operation steps are as follows: after the above-mentioned raw materials are weighed according to the above-mentioned dosage, they are carefully ground in a mortar, mixed evenly, put into a platinum crucible, put into a muffle furnace, heated to 600°C, and pre-fired at a constant temperature for 5 hours. Then take out the crucible after cooling, pour out the sample, re-grind evenly, put it into the platinum crucible again, sinter in the muffle furnace at 800°C for 50 hours, and turn off the power of the muffle furnace. After cooling, take out the crucible to get a lumpy white sample, which is...

Embodiment 3

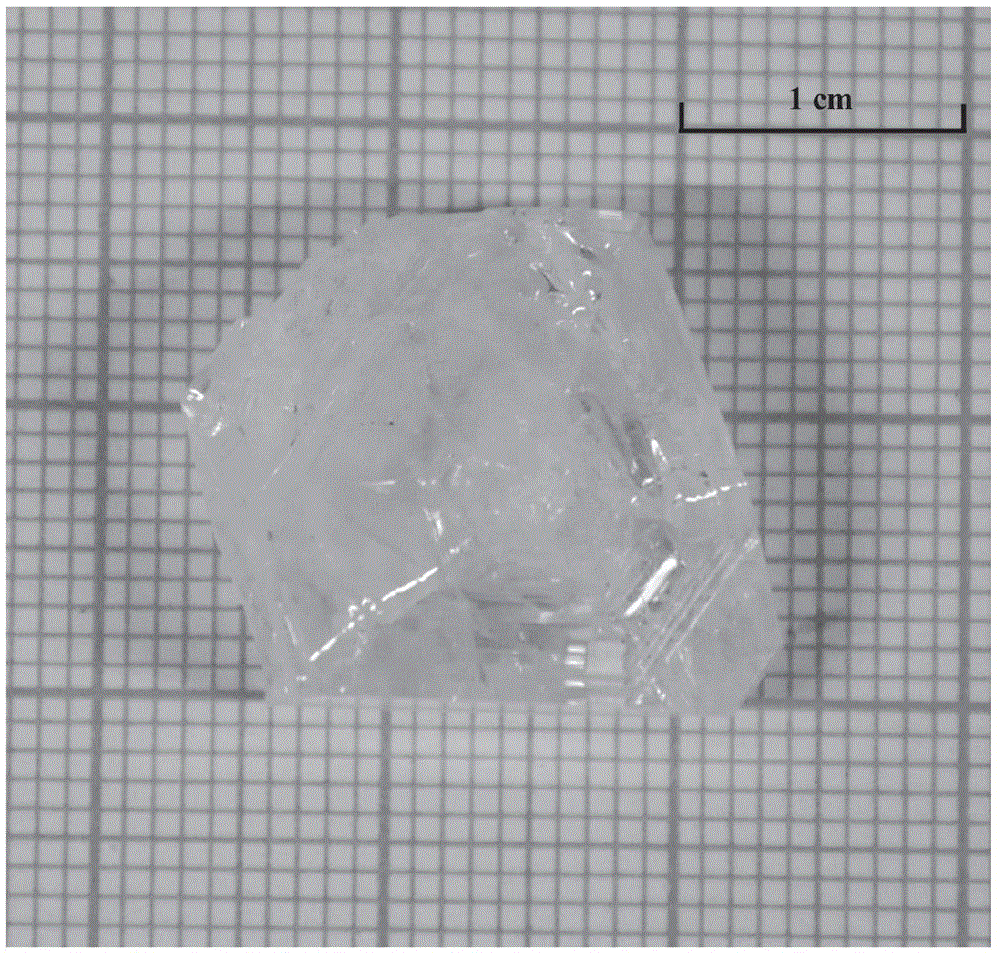

[0041] Growth of Cs by molten salt method 2 GeB 4 o 9 the crystal

[0042]The heating device for crystal growth is an ordinary muffle furnace, the temperature control device is Xiamen Yudian AI-808P temperature controller, and the heat sensing device is a platinum-rhodium thermocouple. Choose Cs 2 O-B 2 o 3 The system acts as a flux to spontaneously nucleate and grow crystal Cs 2 GeB 4 o 9 crystals.

[0043] Raw materials used: Cs 2 CO 3 2.281g (0.007mol)

[0044] GeO 2 0.523g (0.005mol)

[0045] HBO 3 1.917 g (0.031 mol)

[0046] The specific operation steps are as follows: after the above-mentioned raw materials are weighed according to the above-mentioned dosage, mix them evenly, put them into a platinum crucible, put them into a muffle furnace, raise the temperature to 900°C until the original is completely melted, keep the temperature for 10 hours, and then quickly cool down to the saturation temperature Above 5-10°C, then lower the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com