Method for preparing high-purity lycium barbarum acid

A medlaric acid, high-purity technology is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., to achieve the effects of quality improvement, simple method, great application value and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

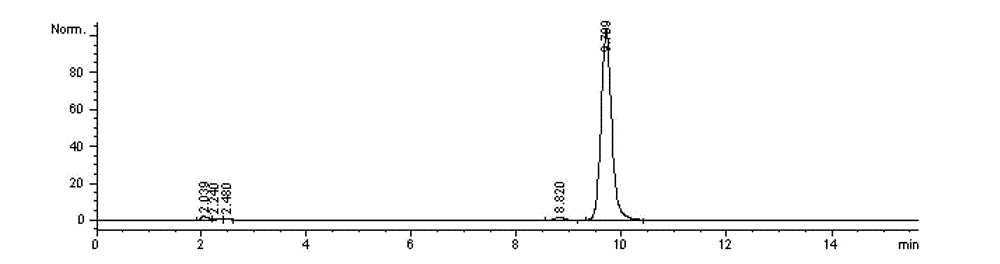

Image

Examples

Embodiment 1

[0036] Weigh 1 kg of dried wolfberry fruit produced in Ningxia, add 30% acetonitrile (15 liters), soak at room temperature (23~27°C) for 4 hours, put it into a food blender and grind it, continue soaking for 10 hours, and use a high-speed centrifuge at 8000 rpm Centrifuge and soak the material for 10 minutes to remove the plant slag, and then filter the obtained material liquid with a stainless steel plate and frame filter to obtain 12.8 liters of clear material liquid after treatment. The feed liquid was vacuum-concentrated at -0.09~-0.95 MPa and 55~65°C with a rotary evaporator until there was no acetonitrile. Obtain 6 liters of aqueous feed solution, add this feed solution in the D-101 macroporous adsorption resin column that 1000 milliliters cleans through the head tank, control the flow rate of passing liquid to be 1 column volume / hour, after loading the column, use 1000 milliliters Water replaced the feed liquid in the column to obtain 7 liters of feed liquid through the...

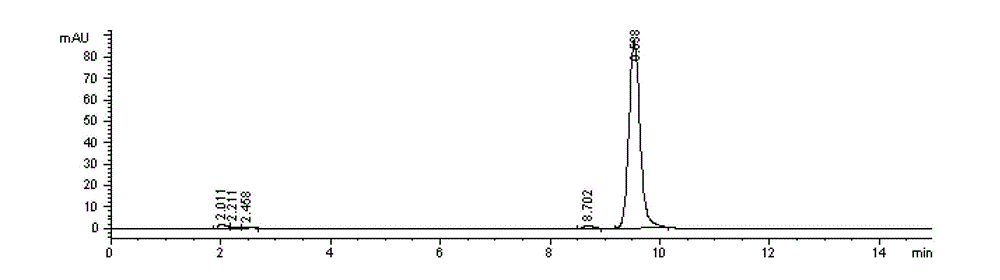

Embodiment 2

[0040] Weigh 1 kg of dried fruit of Lycium barbarum produced in Xinjiang, add an appropriate amount of 30% ethanol, grind them all in a food blender, add 30% ethanol to add enough to 15 liters, and reflux for 3 hours. After the extract is cooled to 23~27°C,

[0041]Use a high-speed centrifuge to centrifuge and soak the material at 8000 rpm to remove plant slag, and the resulting feed liquid is filtered with a stainless steel plate and frame filter to obtain 13.2 liters of clear feed liquid after treatment. The feed liquid was vacuum-concentrated at -0.09~-0.95 MPa and 55~65°C with a rotary evaporator until there was no acetonitrile. Obtain 7 liters of water-based feed liquid, and add this feed liquid to 1000 milliliters of washed AB-8 macroporous adsorption resin columns through the head tank, and control the passing liquid flow rate to be 1 column volume / hour. Water replaced the feed liquid in the column to obtain 8 liters of feed liquid through the column. The collected co...

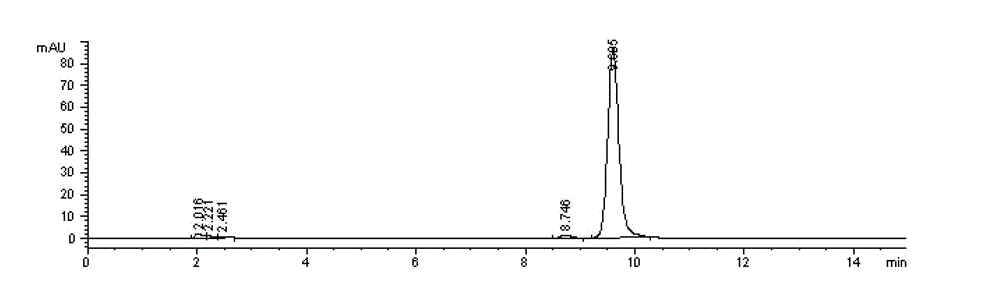

Embodiment 3

[0045] Weigh 1 kg of dry wolfberry fruit produced in Gansu, add appropriate amount of 15 liters of 20% acetone, soak for 8 hours at 23~27°C, put it into a food blender and grind it, then heat and reflux for 2 hours, after cooling, use a high-speed centrifuge to soak the material out The plant slag was removed, and the obtained feed liquid was filtered with a flat frame filter to obtain 12.3 L of treated clear feed liquid. The feed liquid was concentrated in vacuum with a rotary evaporator at -0.09~-0.95 MPa, 55~65°C until there was no acetone. Obtain 6 liters of aqueous feed solution, add this feed solution to 1000 ml of washed HP20 macroporous adsorption resin column through the head tank, control the flow rate of the passing liquid to be 1 column volume / hour, after the column is loaded, replace it with 1000 ml of water The feed liquid in the column was discharged to obtain 8 liters of feed liquid through the column. The collected column feed liquid passes through the OH typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com