Polysilicon ingot and manufacturing method of same

A technology of polycrystalline silicon ingots and manufacturing methods, which is applied in the field of solar cells, can solve problems such as poor quality and many defects in polycrystalline silicon ingots, and achieve the effects of reducing dislocation defects, reducing dislocation defects, and smooth growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] As mentioned in the background technology, polycrystalline silicon ingots produced by existing methods for growing polycrystalline silicon ingots have many defects and poor quality. The inventors found that the reason for this problem is related to the growth process of polycrystalline silicon ingots. The following detailed analysis will be carried out.

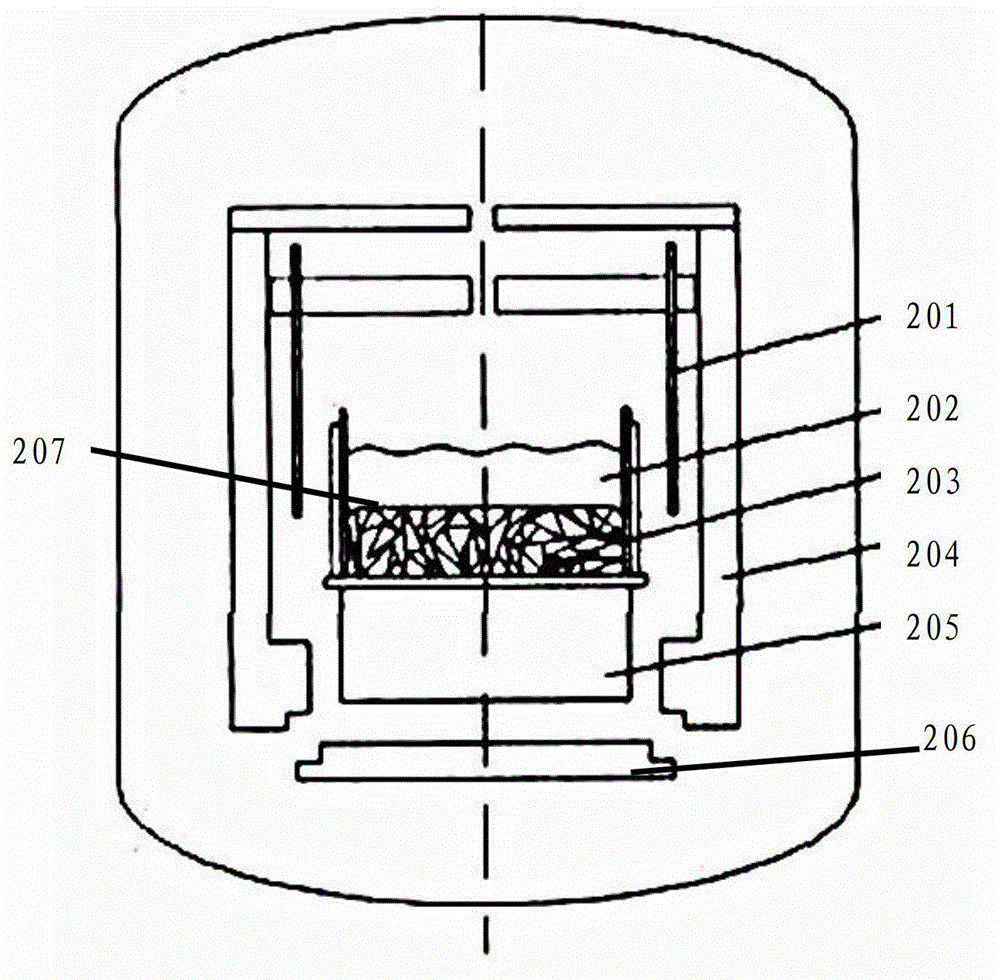

[0042] First, combine figure 2 A conventional polycrystalline ingot furnace used in the art is shown for illustration. Wherein, 201 is a heating electrode, 202 is a silicon melt, 203 is a polysilicon ingot, 204 is a thermal insulation cage, 205 is a cooling block, 206 is a heat dissipation device, and 207 is a silicon liquid interface. The method of using this polycrystalline ingot casting furnace to manufacture polycrystalline silicon ingots is as follows: by closing the cooling device 206, increasing the power of the heating electrode 201, after melting the silicon material completely, opening the cooling device 206...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com