Nitride semiconductor material and method of manufacturing nitride semiconductor crystal

A nitride semiconductor and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, chemical instruments and methods, etc., can solve problems such as high price, GaN peeling, GaN cracks, etc., and achieve good surface flatness and crystal growth. High efficiency and the effect of omitting the grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

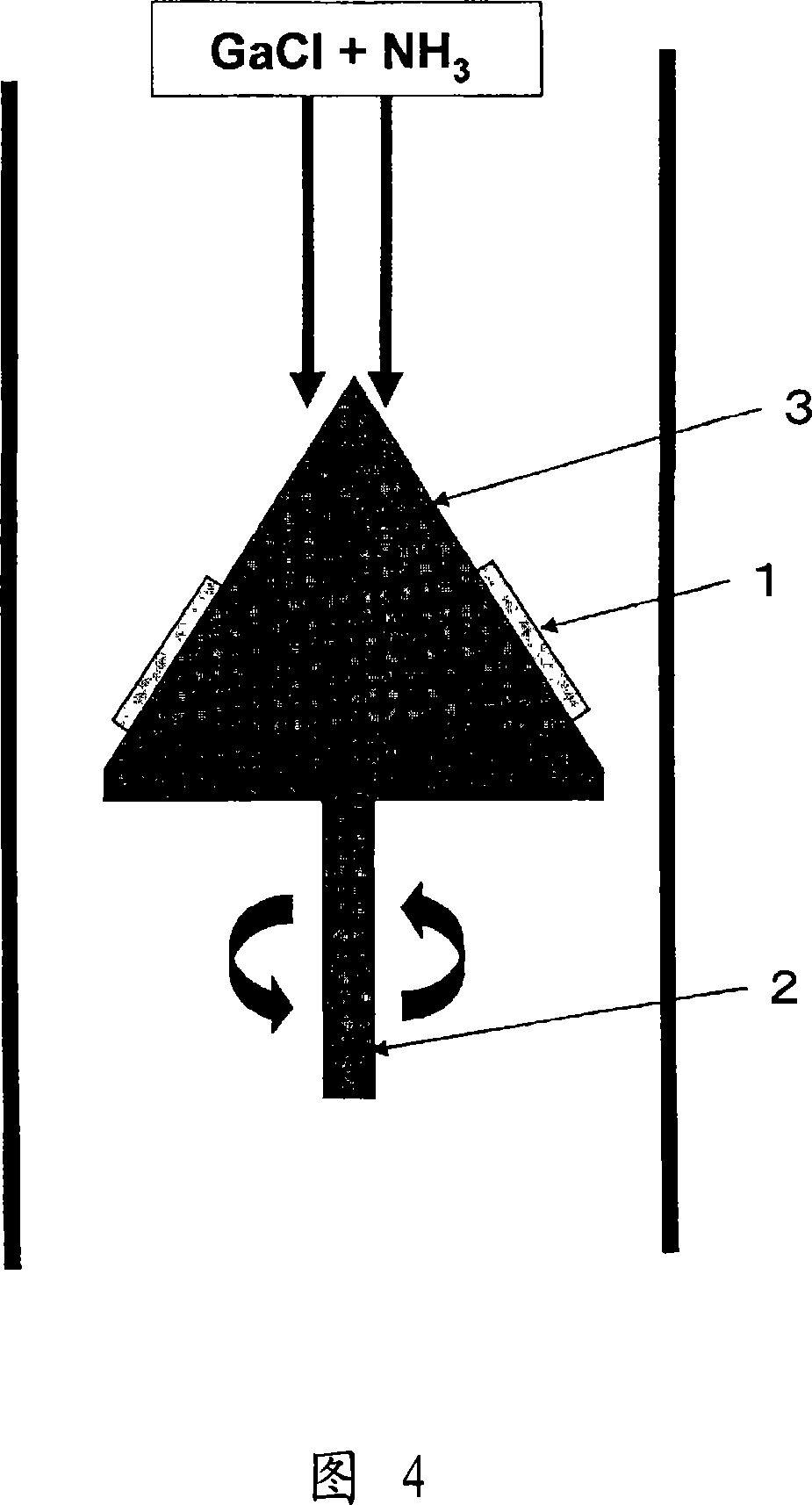

[0080] On a circular substrate with a thickness of 430 μm and a diameter of 5.08 cm (2 inches) with a slight inclination of 0.15° in the m-axis direction from the sapphire (0001) surface, 3 μm of undoped GaN was grown by MOVPE. Then, the substrate on which the GaN layer was grown was put into the HVPE apparatus, and the gas flow angle was set at 80° relative to the normal line of the substrate to grow the GaN layer. The growth conditions by the HVPE method were set as follows.

[0081] HCl partial pressure: 1.14kPa (1.13×10 -2 atm)

[0082] (Hereafter, HCl reacts with Ga metal to generate GaCl)

[0083] NH 3 Partial pressure: 4.58kPa (4.52×10 -2 atm)

[0084] Growth temperature: 1000°C (upstream side substrate end)

[0085] 970°C (downstream substrate end)

[0086] Carrier gas: H 2 (16(L))

[0087] Growth time: 5 hours

[0088] As shown in Figure 1, the crystalline thickness of the grown GaN layer was 170 μm, and no cracks, cracks, or spatially periodic defects were ...

Embodiment 2

[0090] On a circular sapphire (0001) substrate with a thickness of 430 μm and a diameter of 5.08 cm (2 inches), a 3 μm non-doped AlGaN layer was grown by the MOVPE method. The substrate for growing the AlGaN layer is set in the HVPE device, so that the surface of the substrate is parallel to the gas flow (with respect to the normal line of the substrate, the angle of the gas flow is 90°). The growth conditions of the HVPE method were set as follows.

[0091] HCl partial pressure: 1.14kPa (1.13×10 -2 atm)

[0092] (Below, HCl reacts with Ga metal to generate GaCl)

[0093] NH 3 Partial pressure: 4.58kPa (4.52×10 -2 atm)

[0094] Growth temperature: 1000°C (upstream side substrate end)

[0095] 970°C (downstream substrate end)

[0096] Carrier gas: H 2 (16(L))

[0097] Growth time: 5 hours

[0098] The crystal thickness of the grown GaN layer was 170 μm, and no cracks, cracks, or spatially periodic defects were concentrated on the surface. Usually, when only growing t...

Embodiment 3

[0100] On a circular sapphire (0001) substrate with a thickness of 430 μm and a diameter of 5.08 cm (2 inches), a non-doped GaN layer with a thickness of 1.5 μm was formed by the MOVPE method. A superlattice buffer layer in which five sets (each five layers) of InGaN layers and GaN layers each having a thickness of 10 nm were alternately inserted was formed thereon, and a non-doped buffer layer with a thickness of 1.5 μm was grown thereon. GaN layer. The substrate is set in the HVPE apparatus so that the substrate is parallel to the gas flow (with respect to the normal line of the substrate, the angle of the gas flow is 90°). The growth conditions of the HVPE method were set as follows.

[0101] HCl partial pressure: 1.14kPa (1.13×10 -2 atm)

[0102] (Below, HCl reacts with Ga metal to generate GaCl)

[0103] NH 3 Partial pressure: 4.58kPa (4.52×10 -2 atm)

[0104] Growth temperature: 1000°C (upstream side substrate end)

[0105] 970°C (downstream substrate end)

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com