Method for reducing energy consumption of device for preparing olefins from oxy-compound

A technology for producing compounds and olefins, which is applied in the production of hydrocarbons from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of poor heat exchange effect and large volume of heat exchangers, and achieves reduction of total energy consumption, steam saving, and equipment reduction. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

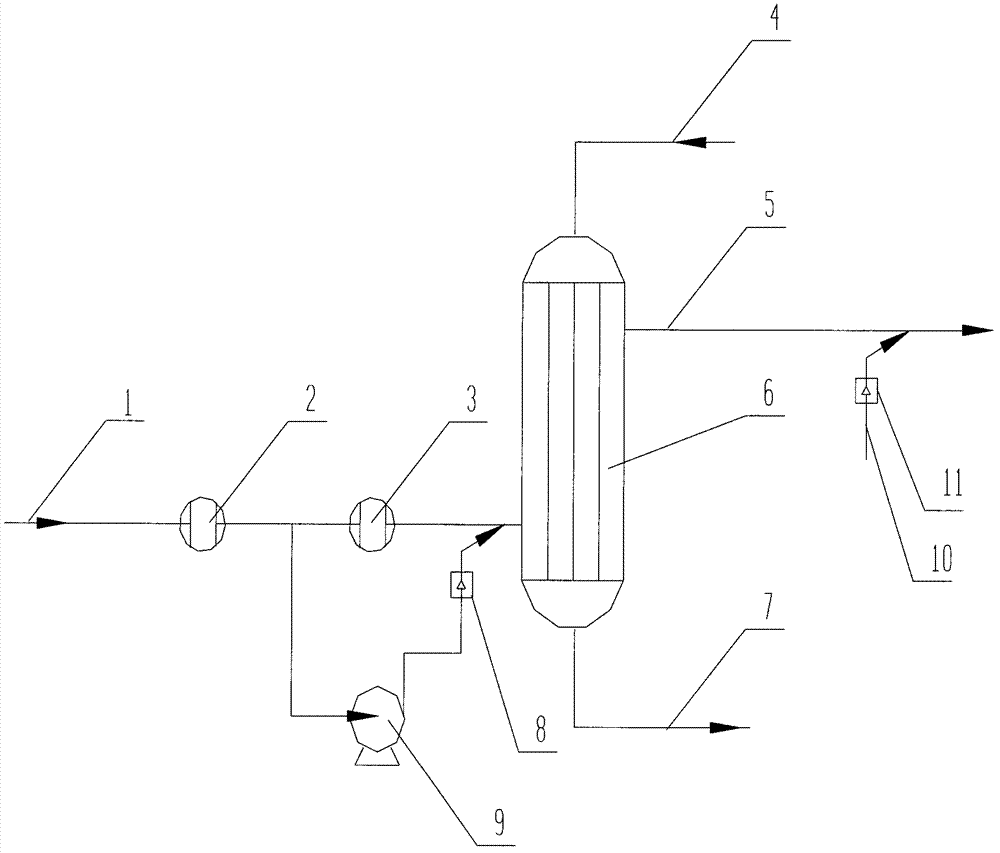

[0025] Such as figure 1 As shown, the liquid oxygenate raw material 1 from outside the device is first preheated to an appropriate temperature through the raw material preheater 2, and the temperature is in the range of 20-150°C, preferably in the range of 40-120°C, and most preferably in the range of 60-120°C , the raw material is in a saturated state, and then divided into two strands: one is heated by the raw material vaporizer 3 to vaporize the raw material and becomes a gas-phase raw material; become atomized liquid-phase raw materials, the atomized liquid-phase raw materials are mixed with gas-phase raw materials, and then enter the raw material / reaction gas heat exchanger 6 in the form of mist flow, and fully exchange with the high-temperature reaction from the reactor to generate oil gas 4 Heat is used to recover high-temperature potential heat, and the raw material after recovery of high-temperature potential heat is completely gasified to become high-temperature gasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com