Poly carboxylic acid water reducing agent adopting tartaric acid as chain transfer agent, and preparation method thereof

A technology of polycarboxylic acid series and chain transfer agent, which is applied in the field of concrete water reducing agent, can solve the problems affecting product performance and chain transfer agent function, achieve high water reducing rate, eliminate health hazards, and avoid high toxicity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

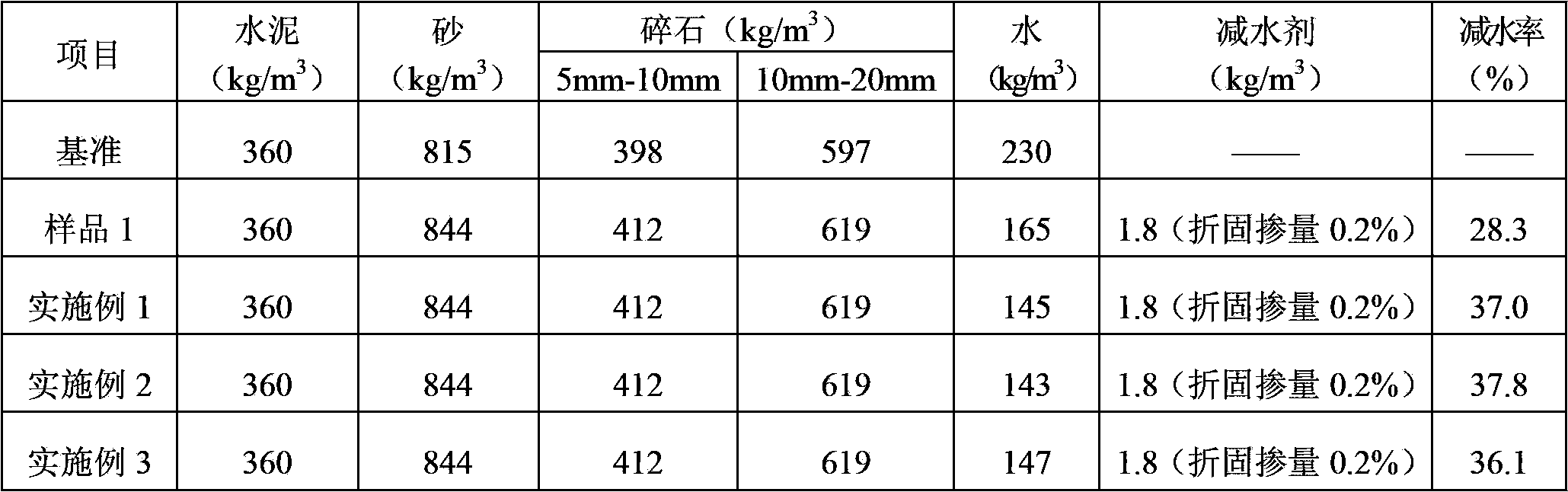

Examples

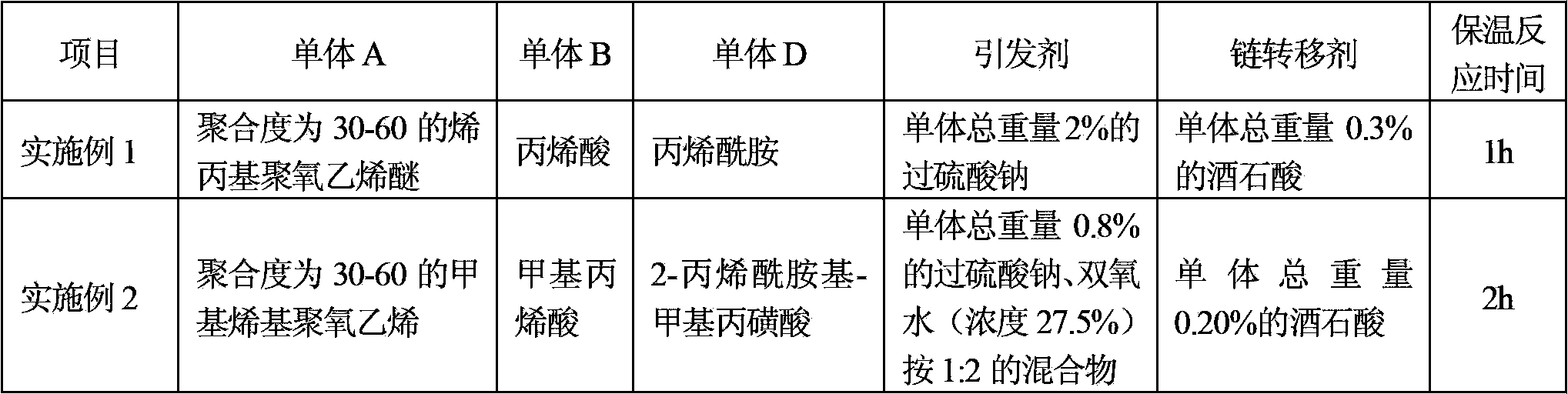

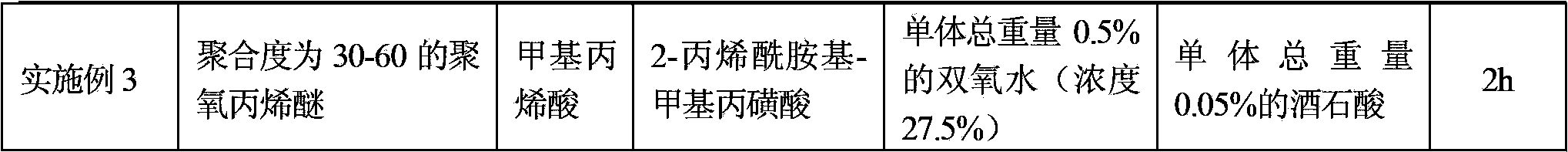

Embodiment 1-3

[0025] Preparation: 0.14mol monomer A, 0.45mol monomer B, 0.02mol monomer C, 0.15mol monomer D, initiator, chain transfer agent;

[0026] Preparation steps:

[0027] a. Dissolve monomer C, monomer D and monomer B twice the amount of monomer D in deionized water, stir evenly, and obtain a small monomer solution for use;

[0028] b. Dissolve the chain transfer agent in deionized water, stir evenly, and obtain the chain transfer agent solution for use;

[0029] c. Put the monomer A and deionized water into the reaction container and heat to dissolve. After the monomer A is completely dissolved, add the remaining monomer B and the initiator, and continue to stir and heat up. When the temperature rises to 60±2°C, start The small monomer solution and the chain transfer agent solution were added dropwise at a uniform speed at the same time, and the drop was completed after 3 hours, and then the reaction was continued with heat preservation. During the dropping process and the heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com