Defoaming master batch for rotational molding and preparation method thereof

A defoaming and masterbatch technology, which is applied in the field of plastic processing, can solve the problems of incomplete solution of air bubbles, intensified thermal oxidation of materials, and difficulty in air bubble discharge, and achieves scientific and reasonable preparation methods, improved surface tension, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

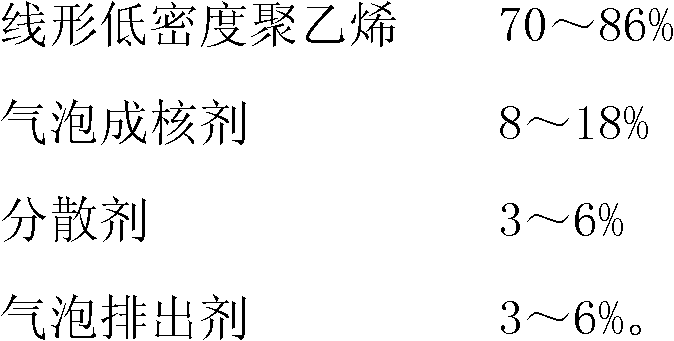

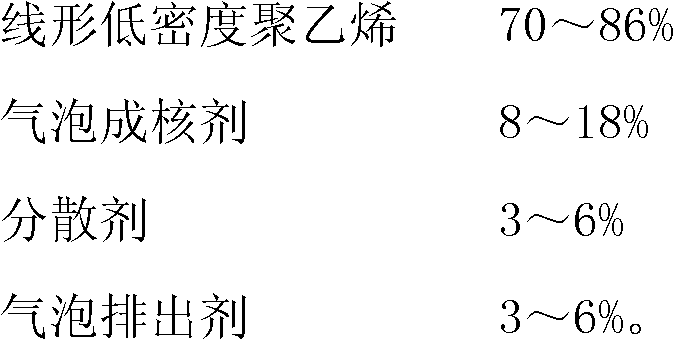

[0017] The rotomolding defoaming masterbatch one of the present invention, the mass percentage of assembled raw materials is composed of:

[0018] Linear low density polyethylene 72%, 1000-2500 mesh calcium carbonate bubble nucleating agent 16%, dispersant calcium stearate 6%, air bubble release agent erucamide 6%, of which linear low density polyethylene: melt Mass flow rate 2~14g / 10min (2.16kg / 190℃), density 0.926~0.940g / cm 3 .

[0019] Preparation method: Mix and stir the assembled raw materials and then extrude and granulate. The mixing speed is 1000 rpm, the mixing temperature is 40-45°C, the mixing time is 5 minutes, and the screw extruder is used for granulation, and the temperature is 150- 160°C.

Embodiment 2

[0021] The rotomolding defoaming masterbatch two of the present invention, the quality percentage of assembled raw material is composed of:

[0022] Linear low density polyethylene 84%, 1000-2500 mesh clay air bubble nucleating agent 10%, dispersant zinc stearate 3%, air bubble release agent oleic acid amide 3%, of which linear low density polyethylene: melt quality Flow rate 2~14g / 10min (2.16kg / 190℃), density 0.926~0.940g / cm 3 .

[0023] Preparation method: Mix and stir the assembled raw materials and then extrude and granulate. The mixing speed is 1100 rpm, the mixing temperature is 35-40°C, the mixing time is 4 minutes, and the screw extruder is used for granulation, and the temperature is 130- 140°C.

Embodiment 3

[0025] Rotational molding defoaming masterbatch three of the present invention, the quality percentage of assembled raw material is composed of:

[0026] Linear low-density polyethylene 76%, 1200-2300 mesh calcium sulfate bubble nucleating agent 14%, dispersant calcium stearate 5%, bubble release agent oleic acid amide 5%, of which linear low-density polyethylene: melt Mass flow rate 2~14g / 10min (2.16kg / 190℃), density 0.926~0.940g / cm 3 .

[0027] Preparation method: Mix and stir the assembled raw materials and then extrude and granulate. The mixing speed is 980 rpm, the mixing temperature is 38-42°C, the mixing time is 6 minutes, and the screw extruder is used for granulation, and the temperature is 160- 165°C.

[0028] Mix masterbatch 1, masterbatch 2, and masterbatch 3 with rotomolding resin for rotomolding, and their properties are shown in Table 1.

[0029] Table 1. Performance table after adding this patent masterbatch (mass parts) during rolling plastic processing

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt mass flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com