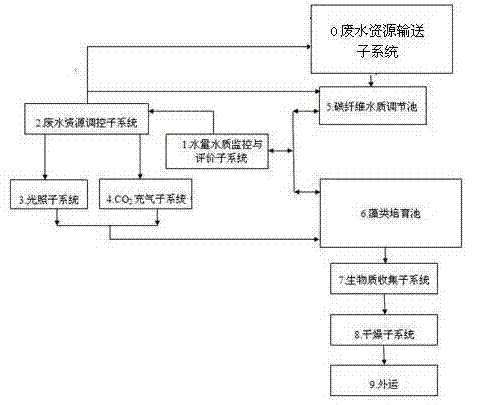

Carbon fiber microalgae cultivating system using wastewater resources

A carbon fiber and carbon fiber technology, applied in the field of carbon fiber microalgae cultivation system, can solve the problems of algae cultivation system research and diversification utilization, etc., to achieve high microbial activity, maximize social benefits, and sustainable development of society. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] According to the above specific implementation methods, taking the main lake carbon fiber demonstration area of East Lake as an example, the specific implementation method steps of this product:

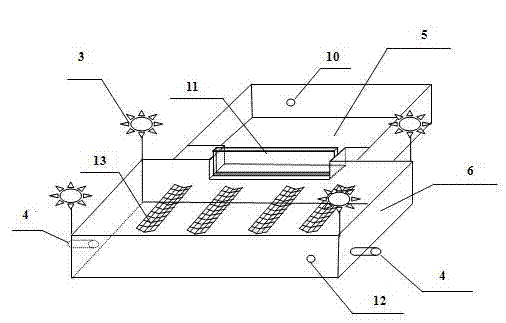

[0062] (1) Design and construction of enclosures and cultivation ponds;

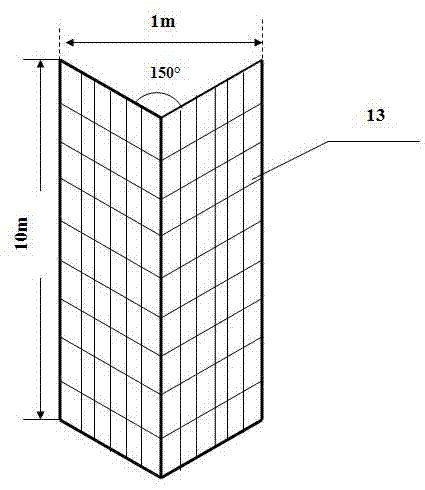

[0063] (2) Design the combined layout scheme of carbon fiber water purification products and algae net frame;

[0064] (3) Production of carbon fiber water purification products and algae net frames;

[0065] (4) Assemble carbon fiber water purification products and algae net frame combination system;

[0066] (5) Install water quantity and quality monitoring system, etc.;

[0067] (6) Install CO 2 inflation system;

[0068] (7) Install lighting system;

[0069] (8) The waste water resource control system is installed on the computer, and it is connected with the water quantity and quality monitoring system, lighting system, CO 2 The inflation system realizes real-time monit...

Embodiment 2

[0074] According to the specific implementation above, taking the sewage treatment plant as an example, the implementation method steps of the sewage treatment plant:

[0075] (1) Design and build a regulating tank, a cultivation tank and a pipe network connection system of a corresponding scale downstream of the tail water discharge of the secondary sedimentation tank of the sewage treatment plant;

[0076] (2) Design the combined layout scheme of carbon fiber water purification products and algae net frame;

[0077] (3) Production of carbon fiber water purification products and algae net frames;

[0078] (4) Assemble carbon fiber water purification products and algae net frame combination system;

[0079] (5) Install water quantity and quality monitoring system, etc.;

[0080] (6) Install CO 2 inflation system;

[0081] (7) Install lighting system;

[0082] (8) The waste water resource control system is installed on the computer, and it is connected with the water quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com