Magnesium deoxidizer, and production method and use method thereof

A magnesium deoxidizer and production method technology, applied in the field of steelmaking and refining, can solve the problems of low magnesium yield and magnesium addition, and achieve the effects of simple process, safe use, and improved properties and forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

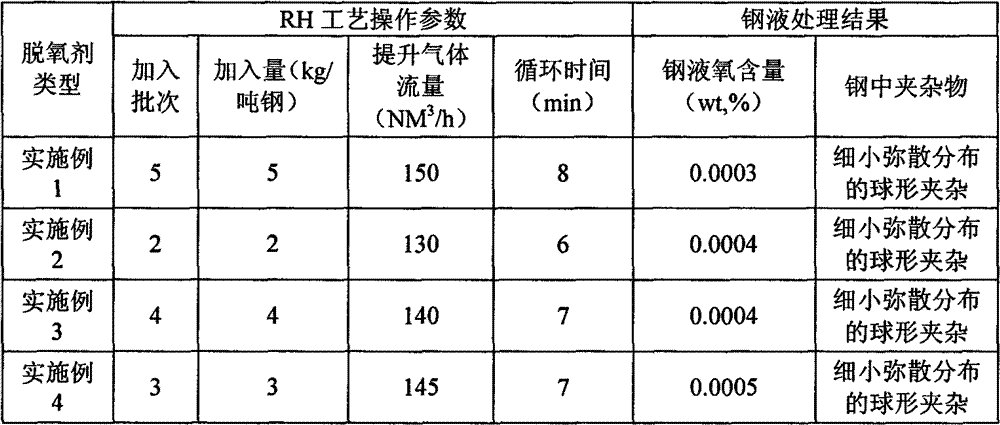

Examples

Embodiment 1

[0018] (1) weigh the following raw materials by the following percentages by weight: magnesia powder 70%, carbon powder 30%, nickel powder content is 10% of magnesia powder and carbon powder gross weight, described magnesia powder, carbon powder and The particle size of nickel powder is 120 mesh;

[0019] (2) Mechanically mix the raw material powder and the binding agent in a mixer, the mixing time is 2.5 hours, the binding agent is carboxymethyl cellulose, and the addition accounts for 2% of the total amount of materials;

[0020] (3) Use a roller press to press into blocks, and the pressure of the roller press is 600Kg / cm 2 , the block particle size is 10mm;

[0021] (4) Crushing the compacted briquette, and screening out a particle size of 3-5mm particles as a finished deoxidizer;

[0022] (5) Dry and package the screened products for later use. The drying temperature is 150° C., and the drying time is 2 hours.

Embodiment 2

[0024] (1) weigh the following raw materials by the following percentages by weight: magnesia powder 80%, carbon powder 20%, nickel powder content is 15% of magnesia powder and carbon powder gross weight, described magnesia powder, carbon powder and The particle size of nickel powder is 200 mesh;

[0025] (2) Mechanically mix the raw material powder and the binding agent in a mixer, the mixing time is 3 hours, the binding agent is carboxymethyl cellulose, and the addition accounts for 3% of the total amount of materials;

[0026] (3) Use a roller press to press into blocks, and the pressure of the roller press is 600Kg / cm 2 , the block particle size is 20mm;

[0027] (4) Crushing the compacted briquette, and screening out a particle size of 3-5mm particles as a finished deoxidizer;

[0028] (5) The selected products are dried and packaged for later use, the drying temperature is 135° C., and the drying time is 2.5 hours.

Embodiment 3

[0030] (1) weigh out following raw material by following weight percentage: magnesium oxide powder 70%, carbon powder 30%, the particle size of described magnesium oxide powder and carbon powder is 270 orders;

[0031] (2) Mechanically mix the raw material powder and the binding agent in a mixer, the mixing time is 3.5 hours, the binding agent is carboxymethyl cellulose, and the addition accounts for 3.5% of the total amount of materials;

[0032] (3) Use a roller press to press into blocks, and the pressure of the roller press is 750Kg / cm 2 , the block particle size is 30mm;

[0033] (4) Crushing the compacted briquette, and screening out a particle size of 3-5mm particles as a finished deoxidizer;

[0034] (5) Dry and package the screened products for later use. The drying temperature is 145° C., and the drying time is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com