Method for determining total nitrogen content in nitrate-nitrogen-containing compound fertilizer through post-distillation titration method

A technology of compound fertilizer and nitrate nitrogen, which is applied in the direction of chemical analysis by titration method, can solve the problems of affecting the efficiency of the experiment, difficult to control the process, and low detection results, and achieve accurate quantitative results, convenient methods, and reliable methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

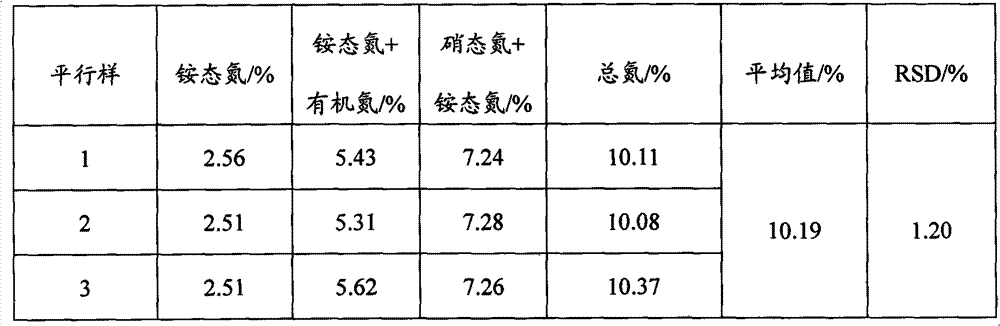

[0014] Detection of Total Nitrogen Content in Compound Fertilizer Samples Containing Nitrate Nitrogen

[0015] (1) Determination of Kjeldahl nitrogen: Kjeldahl nitrogen includes ammonium nitrogen and organic nitrogen. Accurately weigh 1.3507 g of the sample after pulverization and mixing, and add 2 g of mixed catalyst (potassium sulfate: ketone sulfate=20 : 1) and 10mL of concentrated sulfuric acid, insert a long-necked glass funnel, place it on the digestion furnace, adjust its temperature to 470°C, heat until the sample solution is colorless and transparent or off-white, then stop, and the pending nitrogen tube is cooled to room temperature and placed On the azotometer, add boric acid solution into a 500ml triangular flask as the absorption liquid, add 4-5 drops of mixed indicator and place the triangular flask on the liquid ammonia receiving device of the azotometer, add water and sodium hydroxide to the azotometer solution, connect the distillation device, open the azotome...

Embodiment 2

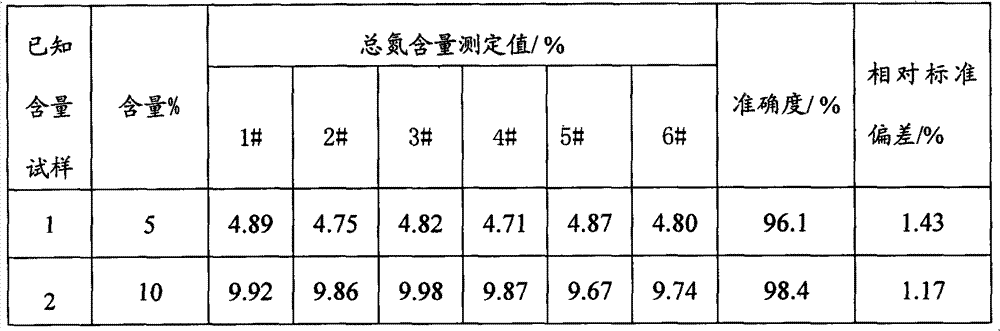

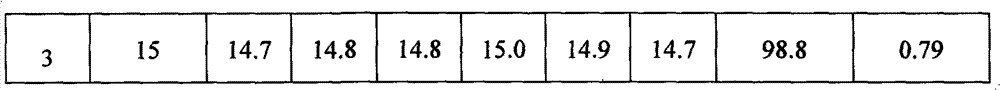

[0021] Determination of Total Nitrogen Content in Compound Fertilizer Samples with Known Content

[0022] (1) Determination of Kjeldahl nitrogen: Kjeldahl nitrogen includes ammonium nitrogen and organic nitrogen. Accurately weigh 0.5675 g of the sample after pulverization and mixing, and add 2 g of mixed catalyst (potassium sulfate: ketone sulfate=20 : 1) and 10mL of concentrated sulfuric acid, insert a long-necked glass funnel, place it on the digestion furnace, adjust its temperature to 470°C, heat until the sample solution is colorless and transparent or off-white, then stop, and the pending nitrogen tube is cooled to room temperature and placed On the azotometer, add boric acid solution into a 500ml triangular flask as the absorption liquid, add 4-5 drops of mixed indicator and place the triangular flask on the liquid ammonia receiving device of the azotometer, add water and sodium hydroxide to the azotometer solution, connect the distillation device, open the azotometer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com