AnodePositive electrode material of lithium ion battery with porous laminated structure and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of increased side reactions, decreased cycle stability, and failure to reach, and achieve improved contact, simplified preparation process, and long-term use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

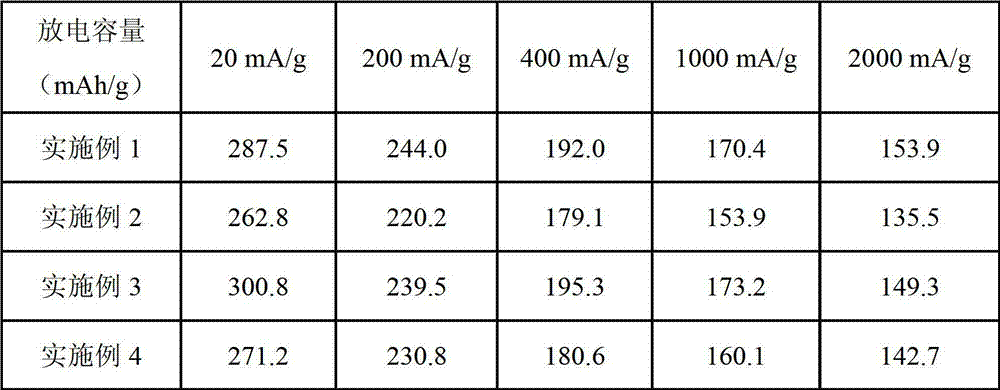

Embodiment 1

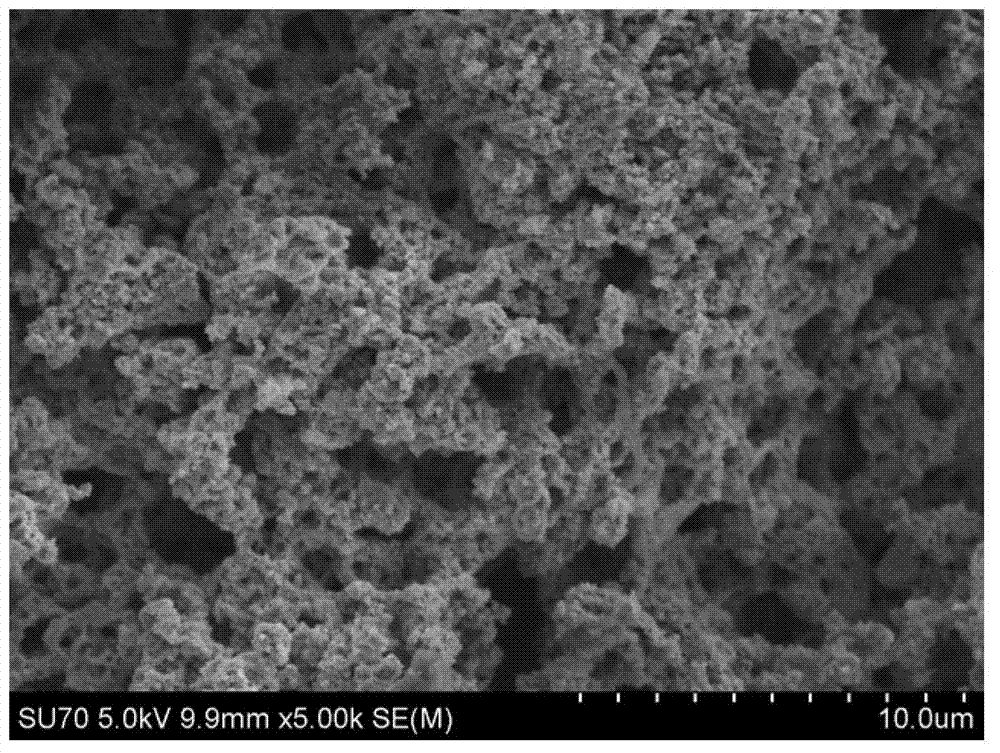

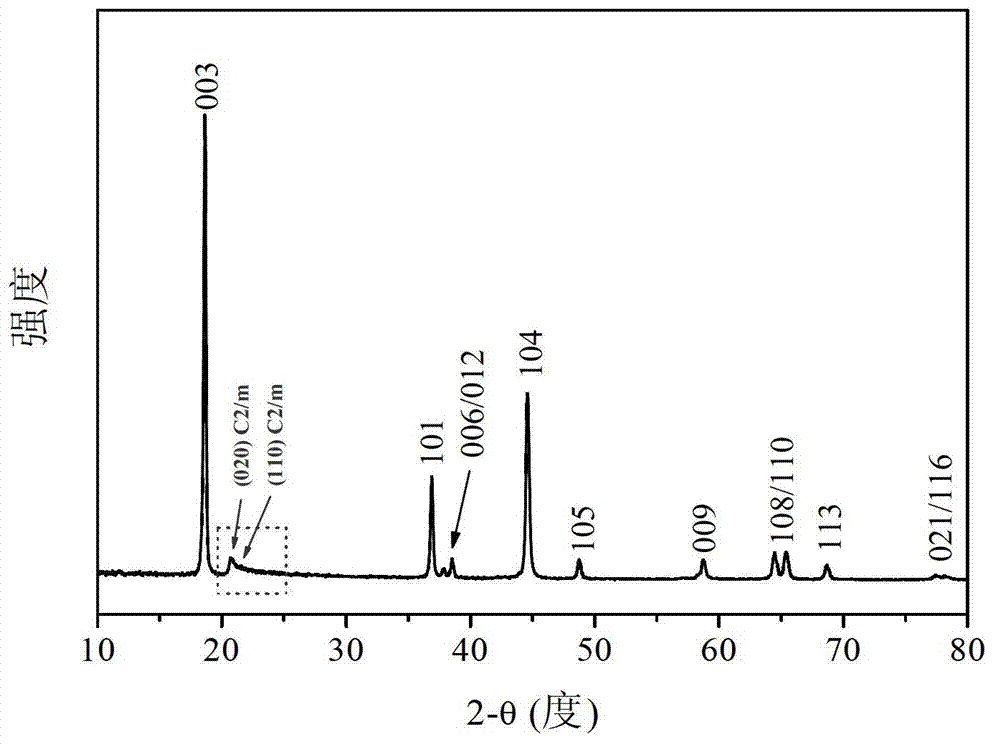

[0031] 1) Dissolve 1.5g of agar powder (agar powder, purified (RB), Sinopharm Chemical Reagent Co., Ltd.) in 100mL of deionized water, stir at 95°C to dissolve and form a transparent hot agar solution. According to the molar ratio of 1.236:0.54:0.13:0.13, the raw material LiNO 3 , Mn(CH 3 COO) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in this hot agar solution (to which an excess of 3% lithium salt is added to counteract the loss of lithium at high temperature), forming a red transparent solution in which lithium salt, nickel salt, manganese salt and cobalt salt The total concentration of 0.5mol / L. The obtained red transparent solution was cooled to 20° C. to obtain a red jelly-like gel. The red jelly-like gel was frozen in an anti-riot refrigerator to -20°C, and the frozen gel was placed in a freeze dryer at -60°C for 3 days to freeze-dry to remove water therein to obtain an aerogel.

[0032] 2) Put the airgel into a box-type furnace, heat ...

Embodiment 2

[0038] 1) Dissolve 1.5g of agar powder (agar powder, purified (RB), Sinopharm Chemical Reagent Co., Ltd.) in 100mL of deionized water, stir at 95°C to dissolve and form a transparent hot agar solution. According to the molar ratio of 1.236:0.54:0.13:0.13, the raw material LiNO 3 , Mn(CH 3 COO) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in this hot agar solution (to which an excess of 3% lithium salt is added to counteract the loss of lithium at high temperature), forming a red transparent solution in which lithium salt, nickel salt, manganese salt and cobalt salt The total concentration of 0.5mol / L. The obtained red transparent solution was cooled to 30° C. to obtain a red jelly-like gel. The red jelly-like gel was frozen in a riot-proof refrigerator to -20°C, and the frozen frozen gel was placed in a freeze dryer at -50°C for 2 days to remove water to obtain an aerogel.

[0039]2) Put the airgel into a box-type furnace, heat up to 550°C at a...

Embodiment 3

[0045] Dissolve 1.5 g of agar powder (agar powder, purified (RB), Sinopharm Chemical Reagent Co., Ltd.) in 100 mL of deionized water and stir at 90 °C to dissolve to form a transparent hot agar solution. According to the molar ratio of 1.236:0.56:0.16:0.08, the raw material LiNO 3 , Mn(CH 3 COO) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in hot agar solution (in which an excess of 3% lithium salt is added to counteract the loss of lithium at high temperature), forming a red transparent solution in which lithium salt, nickel salt, manganese salt and cobalt salt The total concentration is 0.2mol / L. The obtained red transparent solution was cooled to 25° C. to obtain a red jelly-like gel. The red jelly-like gel was frozen in a riot-proof refrigerator to -20°C, and the frozen frozen gel was placed in a freeze dryer at -60°C for 3 days to remove water to obtain an aerogel. Put the airgel into a box-type furnace, heat up to 450°C at a heating rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com