Plasma generation device and method based on back corona creeping-surface breakdown of catalyst as well as application thereof

A plasma and generating device technology, applied in the field of plasma generation, can solve the problems of energy consumption, reduce the energy efficiency of the reactor, etc., and achieve the effect of improving the effect of purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

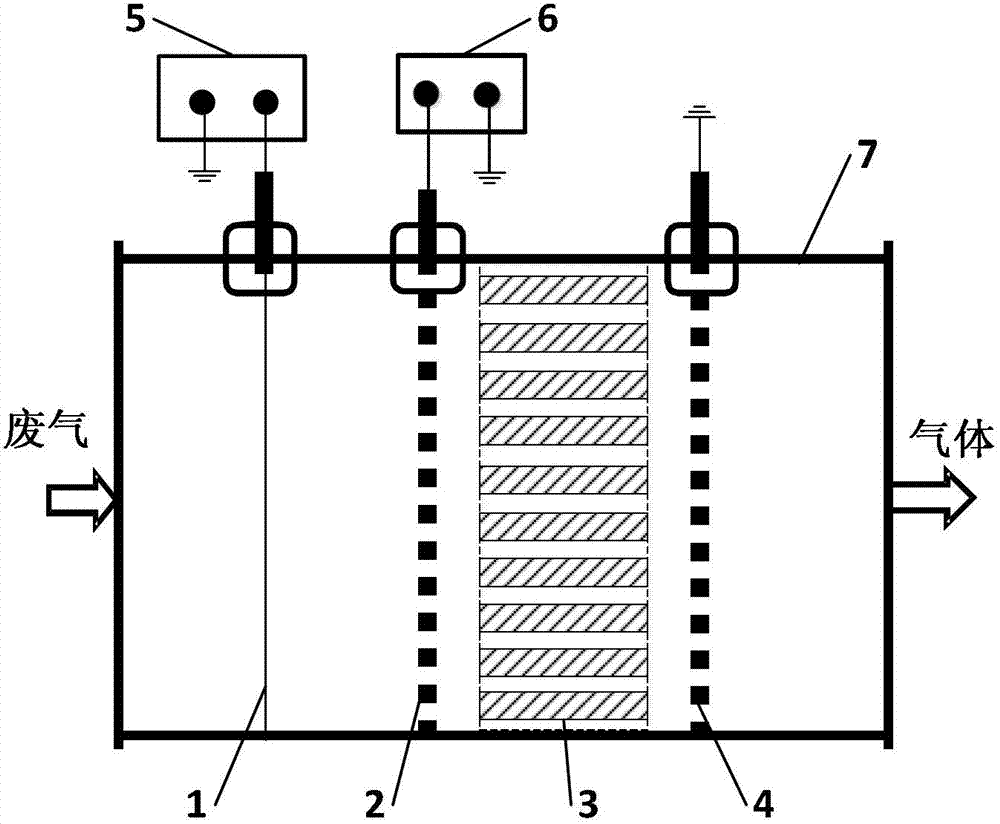

[0028] Such as figure 1 As shown, a plasma generation device based on the surface breakdown of catalyst back corona, including a plasma generator 7, a high voltage power supply 5, a pair of high and low voltage electrodes composed of a corona electrode 1 and a porous electrode 4, an auxiliary electrode 2, Auxiliary power supply 6 and high specific resistance catalyst layer 3; wherein:

[0029] The high and low voltage electrode pairs are set in the plasma generator 7, and the distance between the two electrodes is 3cm; the high specific resistance catalyst layer 3 is set between the high and low voltage electrode pairs; the auxiliary electrode 2 is set between the corona electrode 1 and the high specific resistance catalyst layer 3 The distance between the corona electrode 1 and the corona electrode 1 is 2 cm; one end of the auxiliary power supply 6 is connected to the auxiliary electrode 2, and the other end is grounded; one end of the high-voltage power supply 5 is connected...

Embodiment 2

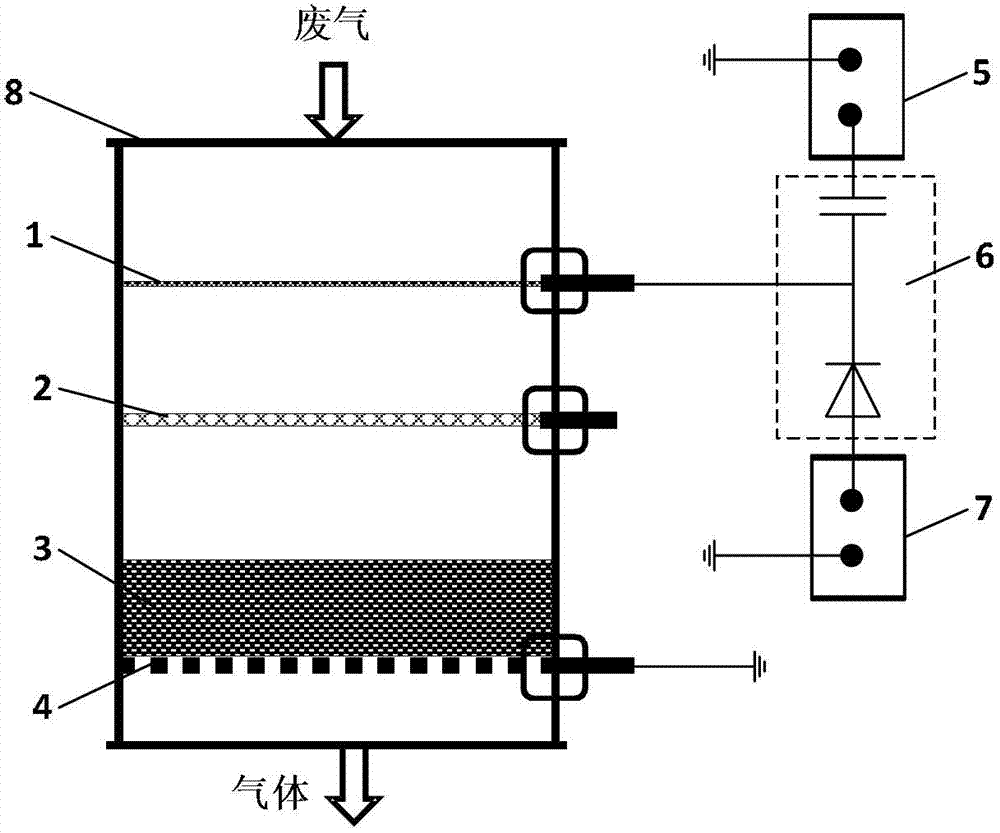

[0042] Such as figure 2 As shown, a plasma generation device based on the surface breakdown of catalyst back corona, including a plasma generator 8, a high voltage power supply, a high and low voltage electrode pair composed of a corona electrode 1 and a porous electrode 4, an auxiliary electrode 2 and a high Specific resistance catalyst layer 3; wherein:

[0043] The high and low voltage electrode pairs are set in the plasma generator 8, and the distance between the two electrodes is 3cm; the high specific resistance catalyst layer 3 is set between the high and low voltage electrode pairs; the auxiliary electrode 2 is set between the corona electrode 1 and the high specific resistance catalyst layer 3 The distance between the corona electrode 1 and the corona electrode 1 is 16 mm; the high-voltage power supply is connected to the corona electrode 1, and the porous electrode 4 is grounded.

[0044] The high-voltage power supply adopts a DC power supply 5 and is composed of a...

Embodiment 3

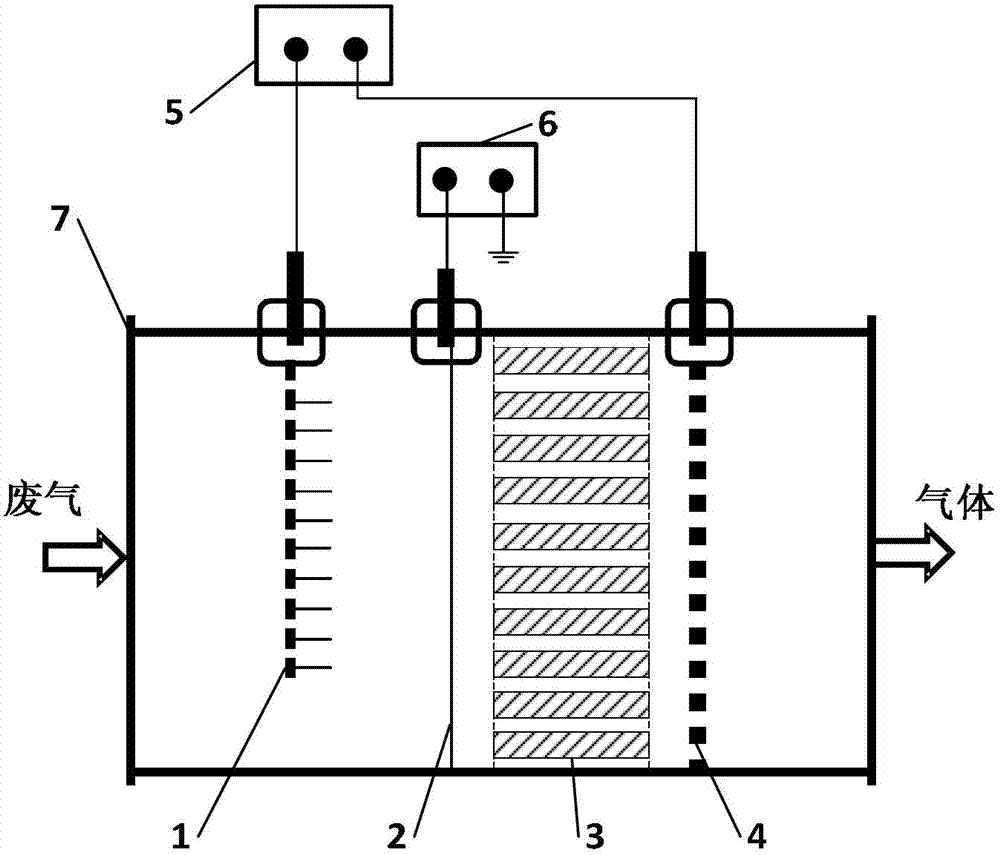

[0054] Such as image 3 As shown, a plasma generation device based on the surface breakdown of catalyst back corona, including a plasma generator 7, a high voltage power supply 5, a pair of high and low voltage electrodes composed of a corona electrode 1 and a porous electrode 4, an auxiliary electrode 2, Auxiliary power supply 6 and high specific resistance catalyst layer 3; wherein:

[0055] The high and low voltage electrode pairs are set in the plasma generator 7, and the distance between the two electrodes is 3cm; the high specific resistance catalyst layer 3 is set between the high and low voltage electrode pairs; the auxiliary electrode 2 is set between the corona electrode 1 and the high specific resistance catalyst layer 3 The distance between the corona electrode 1 and the corona electrode 1 is 15mm; one end of the high-voltage power supply 5 is connected to the corona electrode 1, and the other end is connected to the porous electrode 4; one end of the auxiliary pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com