Polyester fiber and method for preparing same

A technology of polyester fiber and manufacturing method, applied in the field of high-strength and low-modulus polyester fiber and its manufacturing, can solve the problems of passenger injury, rigid seat belt, low modulus elongation, etc., to protect safety, reduce heat Effects of Deformation and Strength Reduction, Wear Resistance and Thermal Strength Retention Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

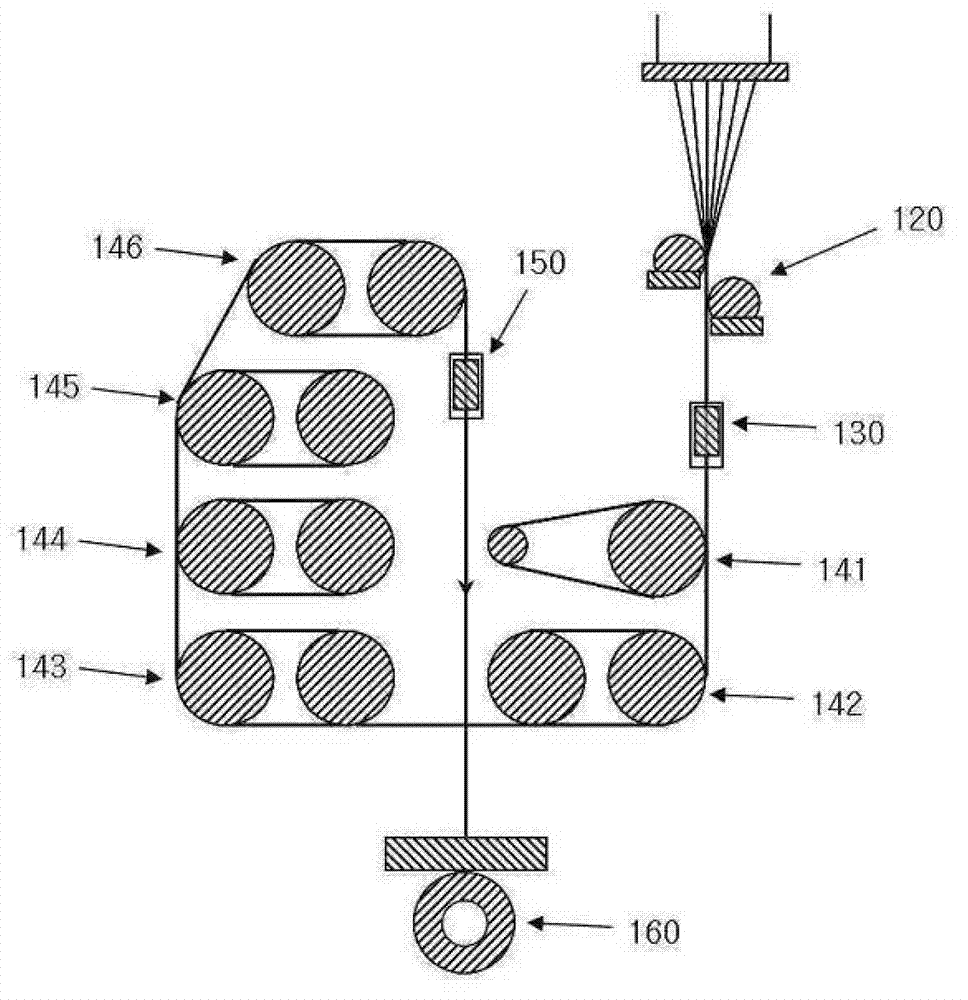

[0070] After melt-spinning a polyester polymer having a predetermined intrinsic viscosity, cooling it to produce an undrawn polyester yarn, and then heat-treating the undrawn yarn at a prescribed draw ratio to produce a polyester fiber. At this time, the intrinsic viscosity of the polyester polymer, the spinning speed, the spinning tension, the spinning temperature conditions, the draw ratio, and the heat treatment temperature during the melt spinning process are shown in Table 1 below, and other conditions follow the guidelines for the production of polyester. Normal conditions for fibers.

[0071] Table 1

[0072] Classification

Example 1

Example 2

Example 3

Example 4

Example 5

Intrinsic viscosity of chips (dl / g)

1.05

1.07

1.12

1.18

1.2

Spinning temperature (°C)

283

290

293

295

295

5.7

5.6

5.5

5.4

5.3

Heat treatment temperature (°C)

240

...

manufacture example 1~5

[0105] Using the polyester fibers produced in Examples 1 to 5, after weaving a webbing with a narrow loom, a seat belt sample was produced through a dyeing process, and the performance was measured by the following method.

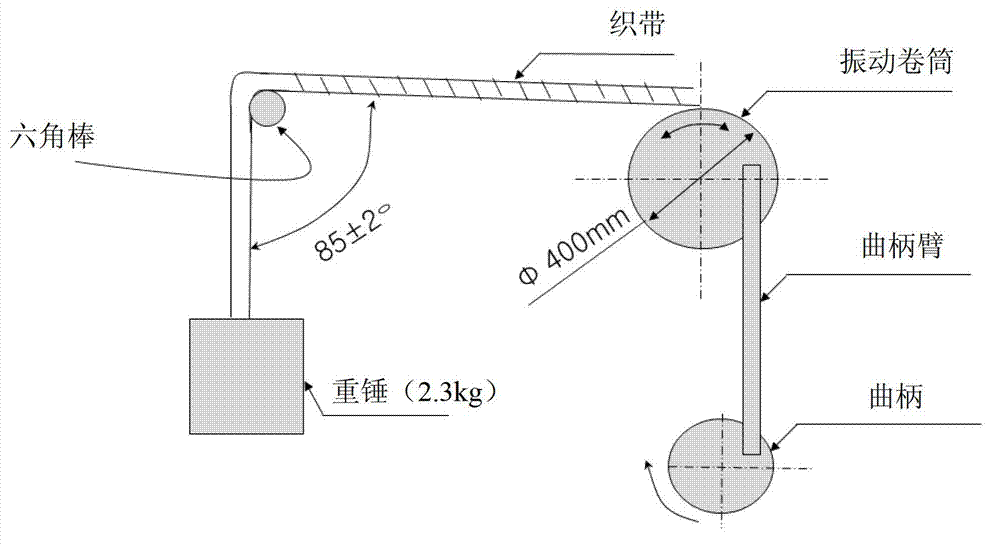

[0106] A) Evaluation of wear resistance by hexagonal bar

[0107] The wear resistance of the safety belt samples passed through a hexagonal bar was measured and evaluated in the following manner.

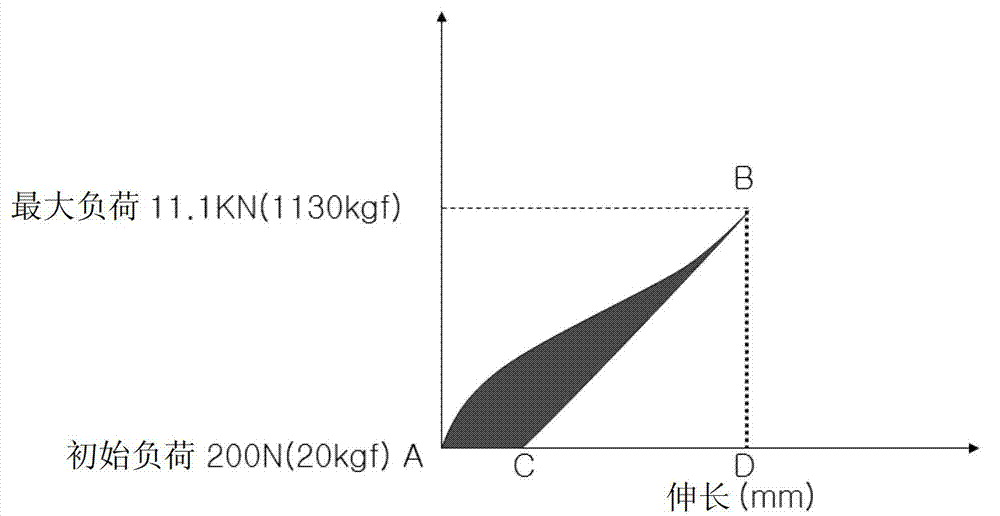

[0108] First, attach the seat belt sample to the figure 2 In the experimental device shown, a weight with a weight of 2.35±0.05kg is suspended on one end of the sample, while the other end straddles the hexagonal rod and is fixed on the vibrating drum. The sample was subjected to 2500 reciprocating frictions at the two corners of the hexagonal bar at 30 ± 1 time per minute and a stroke of 330 ± 30 mm, and then the tensile strength and strength retention of the sample were measured using a universal material testing machine (Instron). At this time, the once-us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com