Toner for electrostatic image development

一种静电荷图像、调色剂的技术,应用在静电荷图像显影用调色剂领域,能够解决画质劣化、难调色剂粒子带电性(带电稳定性、画质恶化等问题,达到抑制带电量的上升、无损线条重现性、优异流动性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (A-1) Preparation process of polymerizable monomer composition

[0038] First, a polymerizable monomer, a colorant, and if necessary, other additives such as a charge control agent and a release agent are mixed to prepare a polymerizable monomer composition. In mixing to prepare the polymerizable monomer composition, for example, a media type disperser is used.

[0039]In the present invention, the polymerizable monomer refers to a monomer having a polymerizable functional group, and the polymerizable monomer is polymerized to form a binder resin. As the main component of the polymerizable monomer, a monovinyl monomer is preferably used. Examples of monovinyl monomers include styrene; styrene derivatives such as vinyltoluene and α-methylstyrene; acrylic acid and methacrylic acid; methyl acrylate, ethyl acrylate, propyl acrylate, and butyl acrylate. Acrylates such as esters, 2-ethylhexyl acrylate and dimethylaminoethyl acrylate; methyl methacrylate, ethyl methacrylate,...

Embodiment

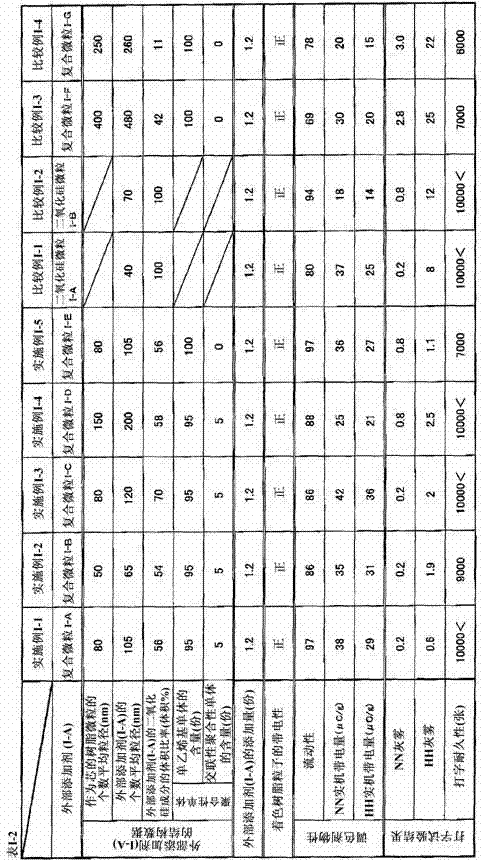

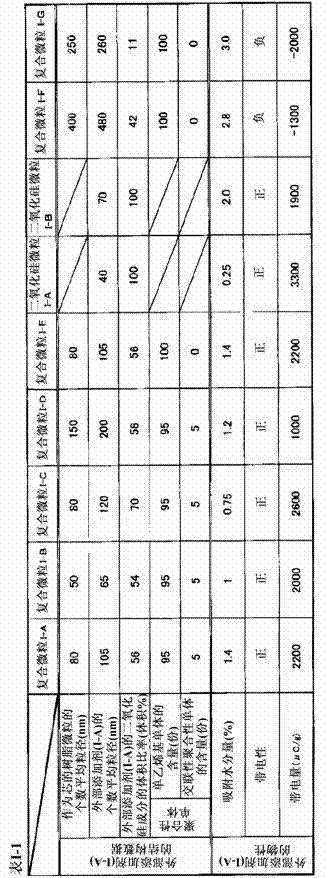

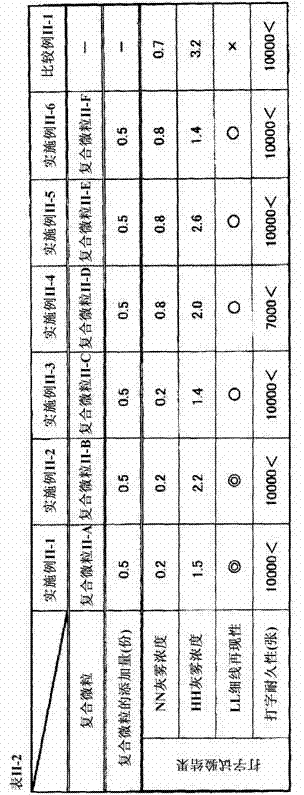

[0174] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated more concretely, this invention is not limited only to these Examples. It should be noted that unless otherwise specified, "parts" and "%" are mass standards.

[0175] The test methods performed in the present examples and comparative examples are as follows.

[0176]

[0177] I-1. Production of core-shell composite particles

manufacture example I-1

[0179] In a container with a stirrer replaced with nitrogen, 3 parts of soft dodecylbenzenesulfonic acid was dissolved in 150 parts of ion-exchanged water, and then 95 parts of styrene was emulsified to prepare a polymerizable monomer emulsion. After raising the temperature of the emulsion to 80° C., 0.6 parts of potassium persulfate dissolved in 10 parts of ion-exchanged water was added, and polymerization was performed for 2 hours. Next, the temperature of the reactor was lowered to 40°C, 5 parts of divinylbenzene was added, stirred for 2 hours, the temperature was raised to 85°C, 0.1 part of potassium persulfate dissolved in 2 parts of water was added, and polymerization was carried out for 4 hours. reaction. Hydroquinone aqueous solution was added as a reaction terminator to terminate the polymerization. The polymerization conversion rate at this time was 99%. Water-soluble substances were removed by ultrafiltration. Adjust the pH and concentration of the emulsion to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com