Braze welding packaging and manufacturing method for making fiber bragg grating into double-peak grating

A technology of optical fiber Bragg and manufacturing method, which is applied in cladding optical fiber, manufacturing tools, optical waveguide and light guide, etc., can solve problems such as temperature and stress difficulties, achieve the effects of reducing the number of gratings, wide application of grating measurement, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

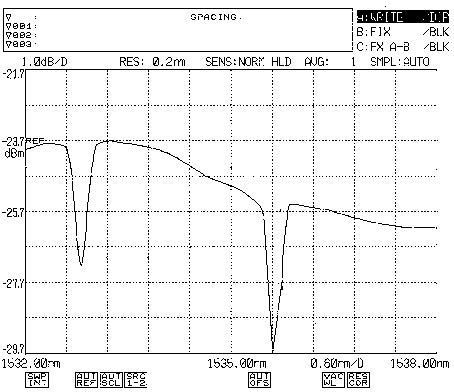

[0016] Example 1: (1) Take a fiber Bragg grating (the central wavelength is 1535.6nm), the grating part is a bare grating, without any protective layer on the surface; the surface is metallized by electroless plating and nickel plating, and the metal The thickness is about 35 microns; (2) if Figure 4 As shown, the metallized fiber Bragg grating 1 is placed in a test tube 2 filled with nitric acid, half is immersed in the nitric acid, and the other half is above the nitric acid liquid level, and kept for 30 minutes. Nitric acid corrodes and removes half of the surface metallization layer along the length of the grating, and keeps half; (3) Place the grating part with the metallization layer in the aluminum alloy tube, and the gap between the metallized grating and the inner wall of the aluminum alloy tube is about 35 microns, put SnPb eutectic solder paste between the grating and the inner wall of the aluminum tube; (4) Place the aluminum alloy tube and the built-in grating in...

Embodiment 2

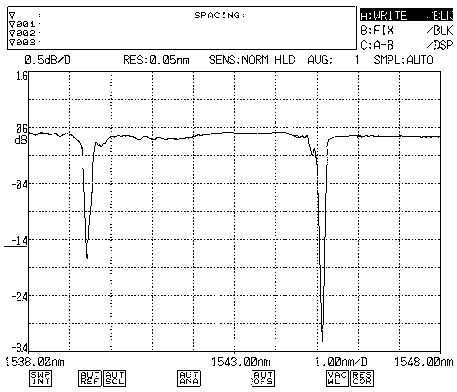

[0017] Example 2: (1) Take a fiber Bragg grating (the central wavelength is 1545.2nm), the grating part is a bare grating, without any protective layer on the surface; the surface is metallized by electroless plating and nickel plating, and the metal The thickness is about 36 microns; (2) if Figure 4 As shown, the metallized fiber Bragg grating 1 is placed in a test tube 2 filled with nitric acid, half of which is immersed in the nitric acid, and the other half is above the liquid level of the nitric acid, and kept for 32 minutes. Nitric acid corrodes and removes half of the surface metallization layer along the length of the grating, and retains half. (3) Place the grating part with the metallized layer in the aluminum alloy tube, the gap between the metallized grating and the inner wall of the aluminum alloy tube is about 38 microns, and put SnPb eutectic solder paste between the grating and the inner wall of the aluminum tube ;(4) Place the aluminum alloy tube and built-i...

Embodiment 3

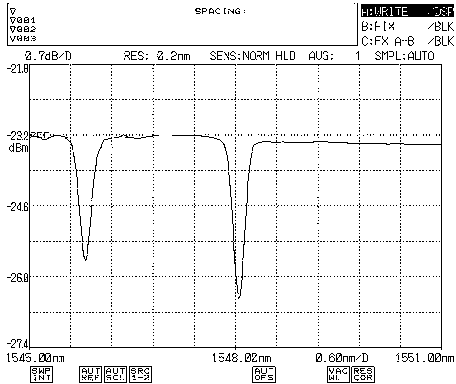

[0018] Example 3: (1) Take a fiber Bragg grating (the central wavelength is 1548.1nm), the grating part is a bare grating, without any protective layer on the surface; the surface is metallized by electroless plating and nickel plating, and the metal The thickness is about 39 microns; (2) if Figure 4 As shown, the metallized fiber Bragg grating 1 is placed in a test tube 2 filled with nitric acid, half of which is immersed in the nitric acid, and the other half is above the liquid level of the nitric acid, and kept for 34 minutes. Nitric acid corrodes and removes half of the surface metallization layer along the length of the grating, and retains half. (3) Place the grating part with the metallized layer in the aluminum alloy tube, the gap between the metallized grating and the inner wall of the aluminum alloy tube is about 39 microns, and put SnPb eutectic solder paste between the grating and the inner wall of the aluminum tube (4) Put the aluminum alloy tube and the built-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com