Composite fiber felt and composite fiber board for automobile inner decoration and preparation methods of composite fiber mat and composite fiber board

A fiber composite and automotive interior technology, which is applied to fiber composite felts and composite fiber boards for automotive interiors, can solve the problems that synthetic fibers are not easy to degrade and are not easy to handle, achieve easy recycling, improve strength and toughness, and have excellent environmental performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

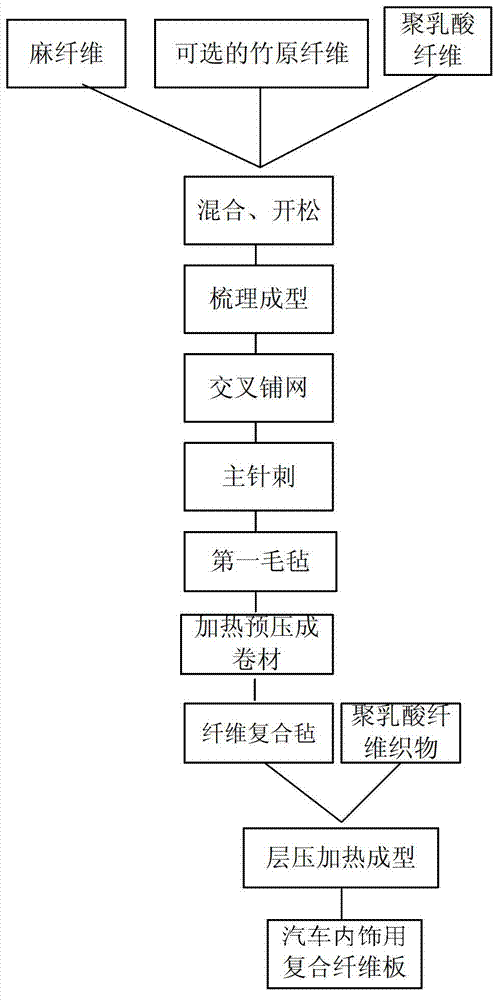

[0048] Such as figure 1 Shown, in one embodiment of the present invention, a kind of preparation method of above-mentioned fiber composite mat for automotive interior is provided, comprising the following steps: mixing hemp fiber, optional bamboo fiber and polylactic acid fiber in proportion, Forming mixed fibers; opening, carding, cross-lapping, and main needling treatment of the mixed fibers in sequence to form a first felt; after the first felt reaches a predetermined weight, it is heated and pre-pressed into a coil to obtain the Fiber composite felt. The preparation method provided by the invention not only has simple processing technology, low energy consumption and high work efficiency, but also the prepared fiber composite felt has excellent performance, is non-toxic and non-polluting.

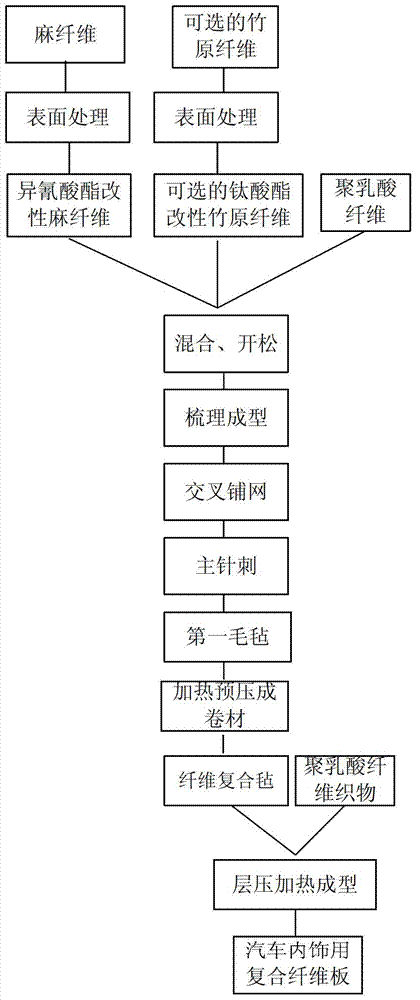

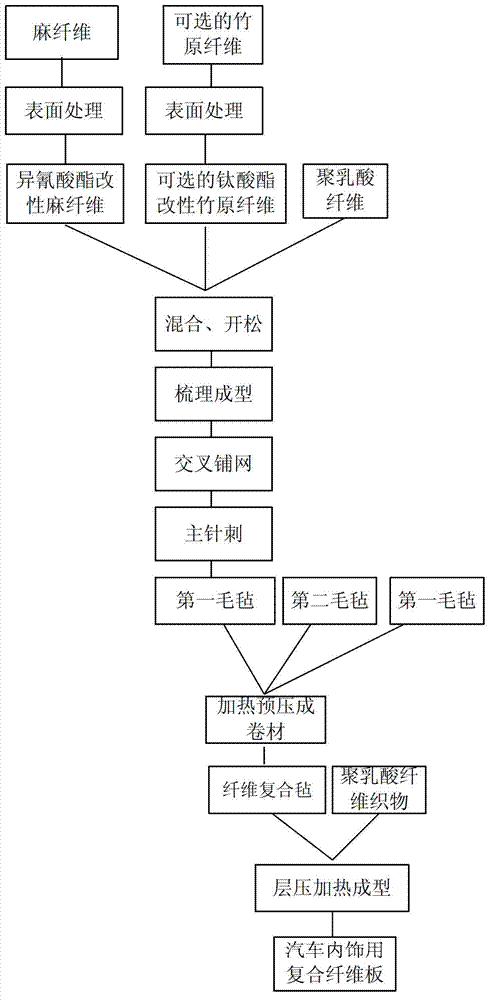

[0049] Such as figure 2 As shown, in one embodiment of the present invention, the step of mixing fibers in the preparation method of the above-mentioned fiber composite felt further ...

Embodiment 1

[0061] Raw materials for the first felt (kg): polylactic acid fiber 40 (7-10cm in length), jute fiber 60 (7-10cm in length). Among them, the breaking strength of the polylactic acid fiber is 4.2cN / dtex, the elongation at break is 28%, and the interlocking strength is 2.8cN / dtex.

[0062] The preparation method of fiber composite felt:

[0063] Mix the polylactic acid fiber and jute fiber through the mixer; put the mixed fiber into the opener for opening and mixing, mix for 30s, and then send it into the cotton box; transport the opened and mixed fiber stored in the cotton box through the airflow to the carding machine for carding; the carded fibers are sent to the web-laying machine for cross-laying; after the laid-up web is folded according to the required requirements, it is sent to the pre-needling machine for pre-needling into felt; The needled felt is sent to the main needling machine for main needling to form the first felt. After reaching the predetermined weight, it i...

Embodiment 2

[0067] The first felt raw material (kg): same as embodiment 1. Among them, the breaking strength of the polylactic acid fiber is 5.5cN / dtex, the elongation at break is 36%, and the joint strength is 2.5cN / dtex.

[0068] The preparation method of fiber composite felt: with embodiment 1.

[0069] The preparation method of composite fiber board: with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com