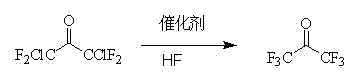

Method for preparing 1,1,1,3,3,3-hexafluoroacetone through gas-phase catalysis

A technology for the catalytic preparation of hexafluoroacetone, which is applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds. Low cost, simple process, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

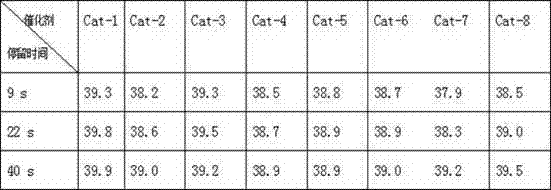

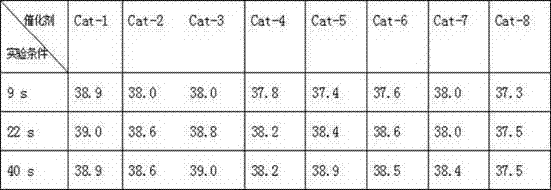

Embodiment 1

[0020] Mix 500 mL of 36.5% hydrochloric acid and 500 mL of 40% hydrofluoric acid to form an acid solution. Pour 150 g of activated carbon particles with a diameter of 2-4mm into the above acidic solution, stir at room temperature for 24 hours, filter, wash with water to neutrality, dry at 120°C for 10 hours, and dry at 300°C for 5 hours, as a catalyst carrier for later use .

[0021] Add 5 g CrCl 3 And 0.5g LaF 3 Dissolve in 50 mL of water to make a solution, weigh 44.5 g of the catalyst carrier and pour into the solution, and stir for 3 hours. Dry for 5 hours at 120°C and 5 hours at 300°C to obtain 10wt% CrCl 3 / 1wt%LaF 3 / C catalyst, denoted as Cat-1.

Embodiment 2

[0023] Prepare 10wt% Cr in the same way as in Example 1. 2 O 3 / 1wt%LaF 3 / C and marked as Cat-2, the difference is that Cr is used 2 O 3 Instead of CrCl 3 .

Embodiment 3

[0025] Prepare 10wt%CrBr in the same way as in Example 1. 3 / 1wt%LaF 3 / C and marked as Cat-3, the difference is that CrBr is used 3 Instead of CrCl 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com