A kind of block copolymer, its preparation method and hydrogel

A technology of block copolymer and hydrogel, applied in the field of block copolymer, its preparation method and hydrogel, can solve the problem that injectable hydrogel does not have electroactivity and the like, achieve good electrochemical response characteristics, Good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a kind of preparation method of block copolymer, comprises the following steps:

[0053] A) Polyethylene glycol or polyethylene glycol monomethyl ether is mixed with lactide and a catalyst for ring-opening polymerization to obtain a block copolymer intermediate, and the lactide is L-lactide or D-lactide - lactide;

[0054] B) mixing the block copolymer intermediate obtained in step A) with a coupling reagent and a compound having the structure of formula (V), and undergoing a condensation reaction to obtain a block copolymer;

[0055]

[0056] in,

[0057] x is the degree of polymerization, 2≤x≤5.

[0058] Preferably, x is 3 or 4.

[0059] First, polyethylene glycol or polyethylene glycol monomethyl ether is mixed with lactide and a catalyst to carry out ring-opening polymerization.

[0060] In the present invention, the polyethylene glycol or polyethylene glycol monomethyl ether is used as the initiator of lactide ring-opening p...

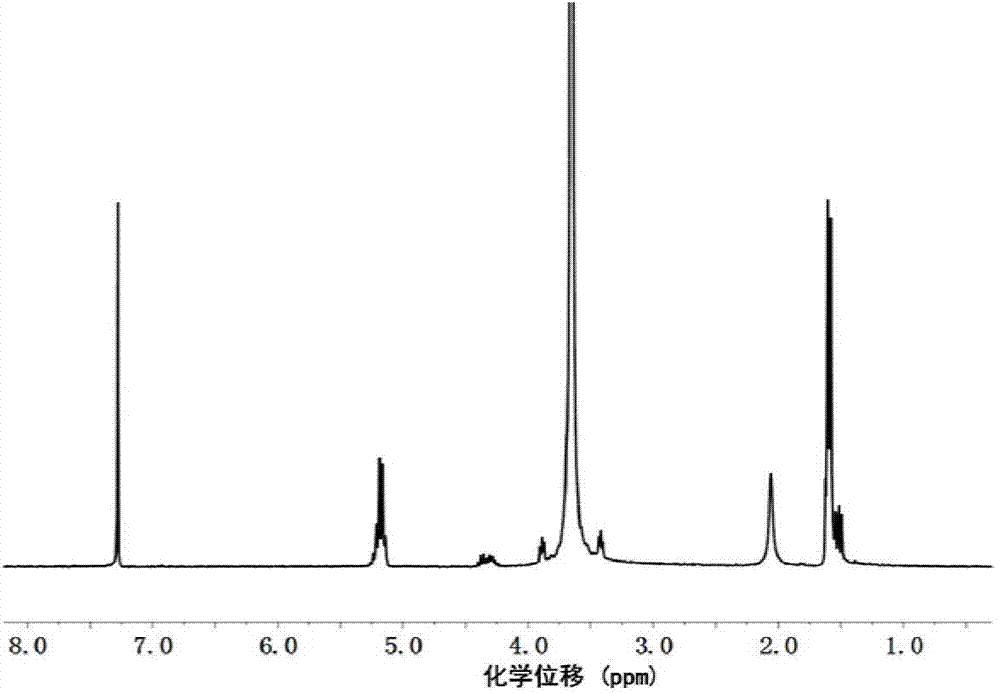

Embodiment 1

[0114] Dissolve 3.68g (0.02mol) of N-phenyl-1,4-p-phenylenediamine in a mixture of 100mL acetone, 100mL water and 25mL concentrated hydrochloric acid to obtain N-phenyl-1,4-p-phenylenediamine mixed solution, and frozen to 0°C; then weighed 4.56g (0.02mol) of ammonium persulfate (APS) and dissolved it in 50mL of 1mol / L HCl aqueous solution to obtain an APS solution, and slowly dropped the APS solution into N-phenyl-1 , in the 4-p-phenylenediamine mixture (dropped in about half an hour), reacted for 3 hours after dropping, then filtered to obtain a solid, and then washed the solid with 0.6mol / L HCl aqueous solution and acetone, and filtered with 0.5mol / L The solid was back-doped with L ammonia water, and finally the solid was washed three times with water to neutrality, freeze-dried and then vacuum-dried to obtain aniline tetramers whose terminal groups were amino groups. The yield was 80%.

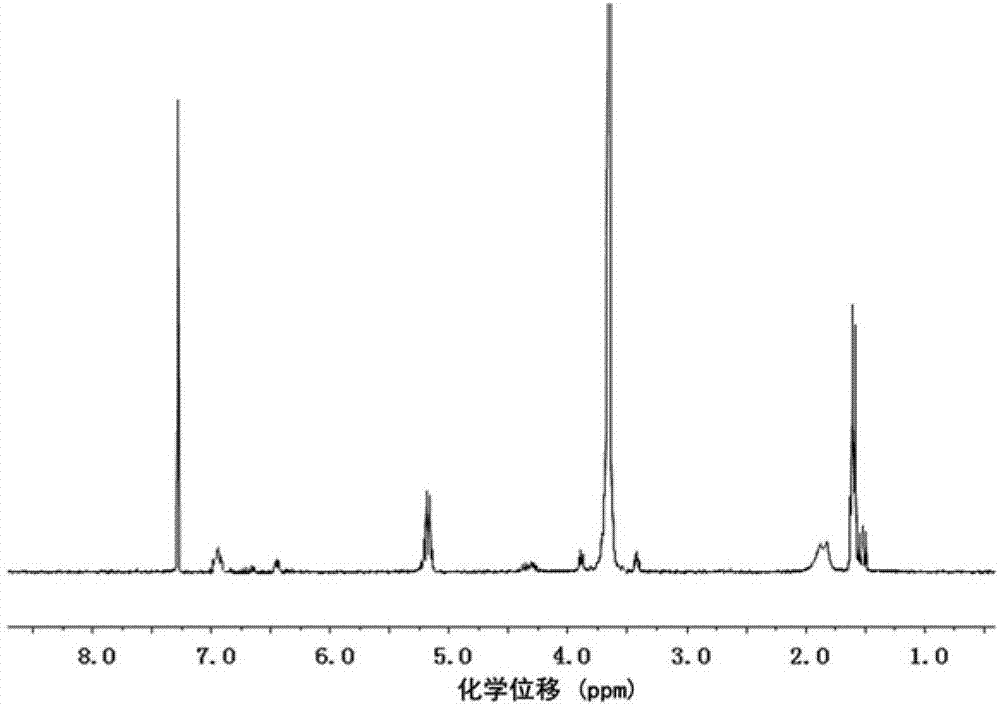

Embodiment 2

[0116]Dissolve 3.5g of N-(4-anilino)-1,4-p-phenylenediamine and 2.6g of N,N-diphenyl-1,4-p-phenylenediamine in 100mL N,N-dimethylformaldehyde A mixture of N-(4-anilino)-1,4-p-phenylenediamine and N,N-diphenyl-1,4-p-phenylenediamine was obtained from a mixture of amide, 15mL water and 15mL concentrated hydrochloric acid, and freeze to 0°C; then weigh 2.28 g (0.01 mol) of ammonium persulfate APS and dissolve it in 50 mL of 1 mol / L HCl aqueous solution to obtain an APS solution, slowly drop the APS solution into N-(4-anilino)-1 , in the mixture of 4-p-phenylenediamine and N,N-diphenyl-1,4-p-phenylenediamine (dropped in about half an hour), react for 1 hour after dropping, and then pour the product into 700mL of water for Precipitate, filter to obtain a solid, wash the solid three times with 0.1mol / L HCl aqueous solution and water successively, then back-dope the solid with 0.1mol / L ammonia water, and finally wash the solid three times with water once until neutral, freeze-dry and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com