Preparation method of pigment red 254

A technology of pigment red and p-chlorobenzonitrile, which is applied in the direction of chemical instruments and methods, organic dyes, azo dyes, etc., can solve the problems of less production equipment, less use of raw materials, and high production costs, and achieve less production equipment and environmental protection. The effect of less pollution and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

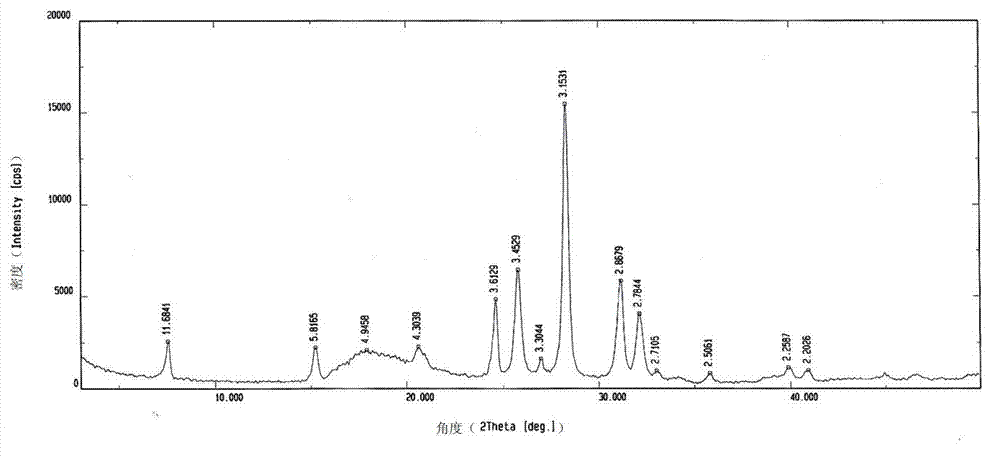

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] (1) Under the protection of nitrogen flow, add 21g of sodium metal, 180g of tert-amyl alcohol and 1g of ferric trichloride to the reaction kettle, heat to 100°C, stir and reflux for 7 hours to prepare sodium tert-amyloxide solution;

[0034] (2) Add 88g of p-chlorobenzonitrile to the sodium tert-amyl alcohol solution at 90°C and stir to dissolve it. At 90°C, add 74g of diisopropyl succinate and 50g of tert-amyl alcohol dropwise to the mixture. The mixed solution was condensed, and the dropping time was 3 hours. After the dropping, it was kept at 100°C for 3 hours. Adding 50g of tert-amyl alcohol was to dilute the concentration of diisopropyl succinate, increase the total amount, and facilitate long-term dropping;

[0035] (3) Add the condensed material to 1200ml of deionized water containing 3g of surfactant EL-40 (castor oil polyoxyethylene ether) for hydrolysis, and hydrolyze at 60°C for 6 hours;

[0036] (4) Eva...

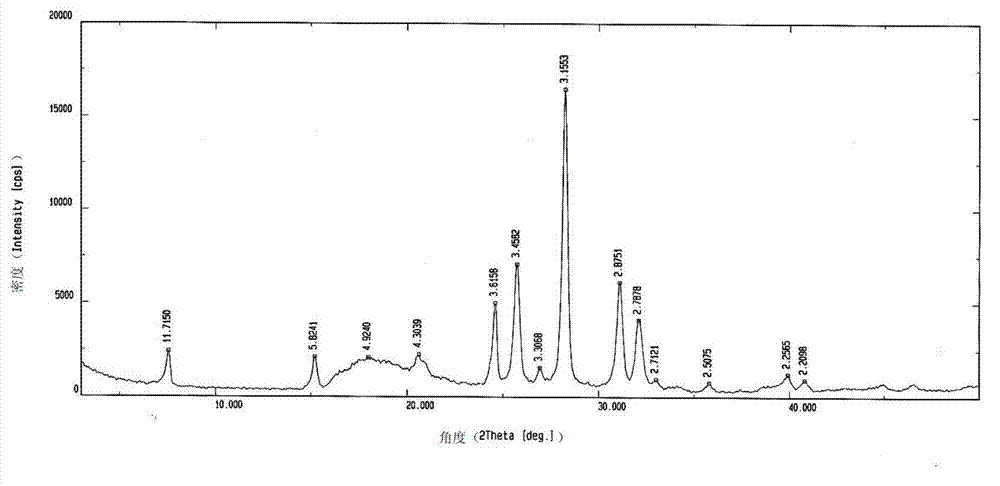

Embodiment 2

[0039] (1) Under the protection of nitrogen flow, add 21g of sodium metal, 210g of tert-amyl alcohol and 0.5g of ferric trichloride to the reaction kettle, heat to 80°C, stir and reflux for 7 hours to prepare sodium tert-amyl alcohol solution;

[0040] (2) Add 80g of p-chlorobenzonitrile to the sodium tert-amyl alcohol solution at 70°C, and stir to dissolve it. At 70°C, add 88g of diisopropyl succinate and 50g of tert-amyl alcohol dropwise to the mixture. The mixed solution was condensed, the time of dropping was 2h, and after the dropping was completed, it was kept at 80°C for 2h;

[0041] (3) Add the condensed material to 1000ml of deionized water containing 3g of surfactant EL-40 (castor oil polyoxyethylene ether) for hydrolysis, and keep it at 40°C for 3 hours;

[0042] (4) Evaporate under reduced pressure to remove tert-amyl alcohol and the by-products generated by the reaction, filter, wash with water, and dry to obtain 100.44 g of crude Pigment Red 254, with a yield of ...

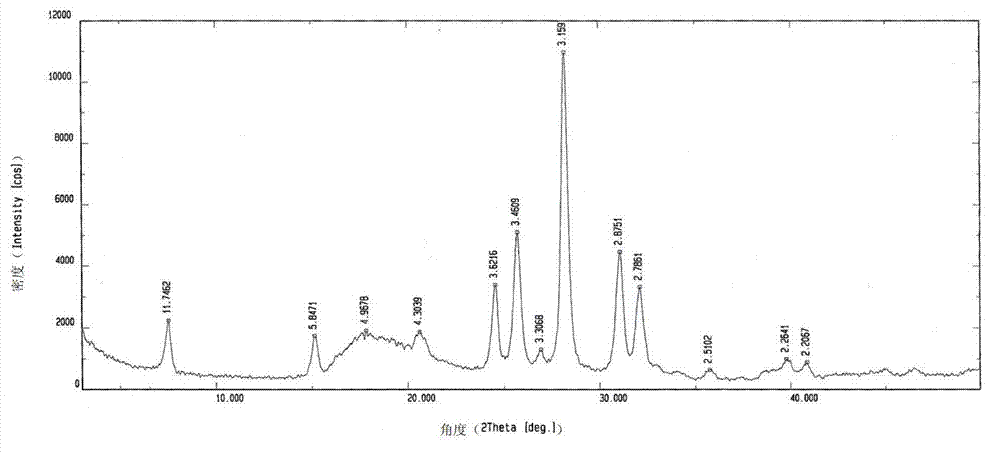

Embodiment 3

[0045] (1) Under the protection of nitrogen flow, add 21g of sodium metal, 290g of tert-amyl alcohol and 1g of ferric chloride into the reaction kettle, heat to 120°C, stir and reflux for 7h to prepare sodium tert-amyloxide solution;

[0046] (2) Add 80g of p-chlorobenzonitrile to the sodium tert-amyl alcohol solution at 100°C, stir to dissolve it, and then add 88g of diisopropyl succinate and 50g of tert-amyl alcohol dropwise to the mixture at 100°C The mixed solution of the mixture was condensed, and the dropwise addition time was 5h, and after the dropwise addition was completed, it was kept at 120°C for 5h;

[0047] (3) Add the condensed material to deionized water containing 3g of surfactant EL-40 (castor oil polyoxyethylene ether) for hydrolysis, and keep it at 80°C for 7 hours;

[0048] (4) Evaporate under reduced pressure to remove amyl alcohol and isopropanol produced by the reaction, filter, wash with water, and dry to obtain 98.2 g of crude Pigment Red 254, with a y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com