Method for preparing carbon nano spiral electromagnetic wave absorbent coated by magnetic material

A magnetic material and carbon nanotechnology, applied in chemical instruments and methods, metal material coating technology, gaseous chemical plating, etc., can solve the problems of low chemical activity, small carbon nanohelix size, complex process, etc., and achieve high-efficiency absorption wave material, achieve impedance matching, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

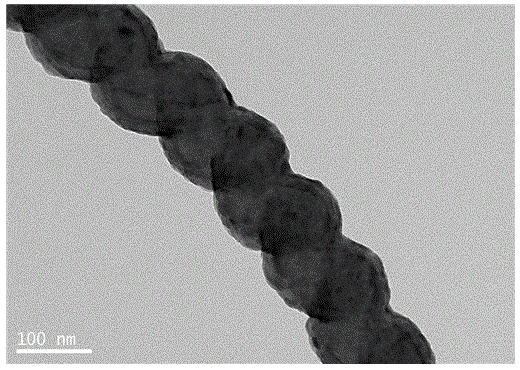

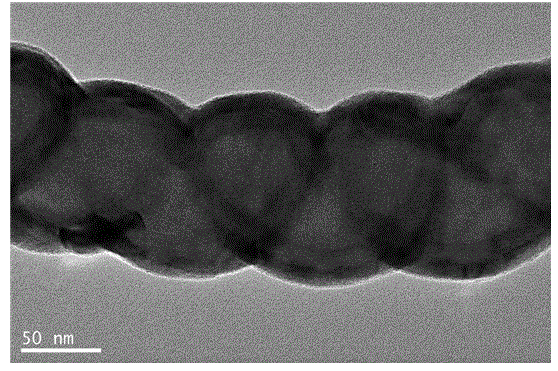

[0036] Copper tartrate precursor was pyrolyzed at 250oC to obtain copper nanoparticles with a diameter of about 50 nm. Acetylene gas was introduced to catalyze acetylene at 250oC to synthesize helical nanofibers. The helical nanofibers were heat-treated in an inert gas at 900oC for 1 hour to obtain a carbon nanohelix with a uniform helical structure and a direct diameter of 100 nm. Disperse the carbon nanohelices on the quartz sheet, dry and transfer to the reaction chamber of the atomic layer deposition equipment, and set the ALD deposition parameters as follows:

[0037] Reaction temperature 150 oC; Reaction source: Al(CH 3 ) 3 and H 2 O is the precursor, both temperatures are at room temperature; carrier gas: 10 sccm high-purity nitrogen; single-cycle pulse, hold and purge time: first H 2 The O pulse is 0.1 s, the hold time is 5 s, and the purge time is 10 s; then Al(CH 3 ) 3 The pulse is 0.015 s, the hold time is 5 s, and the purge time is 10 s; continuous 100 cycles ...

Embodiment 2

[0042] Copper tartrate precursor was pyrolyzed at 250oC to obtain copper nanoparticles with a diameter of about 50 nm. Acetylene gas was introduced to catalyze acetylene at 250oC to synthesize helical nanofibers. The helical fiber was heat-treated in an inert gas at 900oC for 1 hour to obtain a carbon nanohelix with a uniform helical structure and a direct diameter of 100nm. Disperse the carbon nanohelices on the quartz sheet, dry and transfer to the reaction chamber of the atomic layer deposition equipment, and set the ALD deposition parameters as follows:

[0043] Reaction temperature 200 oC; Reaction source: Al(CH 3 ) 3 and H 2 O is the precursor, and the temperature of the precursor is room temperature; carrier gas: 30 sccm high-purity nitrogen; single-cycle pulse, gas holding and purging time: first perform H 2 The O pulse was 0.3 s, the hold time was 6 s, and the purge time was 12 s; then Al(CH 3 ) 3 The pulse is 0.1 s, the hold time is 6 s, and the purge time is 12...

Embodiment 3

[0048] Copper tartrate precursor was pyrolyzed at 250oC to obtain copper nanoparticles with a diameter of about 50 nm. Acetylene gas was introduced to catalyze acetylene at 250oC to synthesize helical nanofibers. The helical fiber was heat-treated in an inert gas at 900oC for 1 hour to obtain a carbon nanohelix with a uniform helical structure and a direct diameter of 100nm. Disperse the carbon nanohelices on the quartz sheet, dry and transfer to the reaction chamber of the atomic layer deposition equipment, and set the ALD deposition parameters as follows:

[0049] Reaction temperature 250 oC; Reaction source: Al(CH 3 ) 3 and H 2 O is the precursor, and the temperature of the precursor is room temperature; carrier gas: 50 sccm of high-purity nitrogen; single-cycle pulse, gas holding and purging time: first carry out H 2 The O pulse was 0.5 s, the hold time was 7 s, and the purge time was 15 s; then Al(CH 3 ) 3 The pulse is 0.4 s, the hold time is 7 s, and the purge time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com