Penetration brazing preparation method of high-content wolfram carbide gradient wear-resisting coating

A wear-resistant coating and tungsten carbide technology, which is applied in the field of high-content tungsten carbide gradient wear-resistant coatings, can solve the problems of difficult to achieve tungsten carbide coating protection, wear resistance, poor corrosion resistance, and easy peeling of coatings, etc., to achieve Small stress, firm bond and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The method for the tungsten carbide wear-resistant composite coating prepared by the infiltration brazing method described in the present embodiment: comprises the following steps:

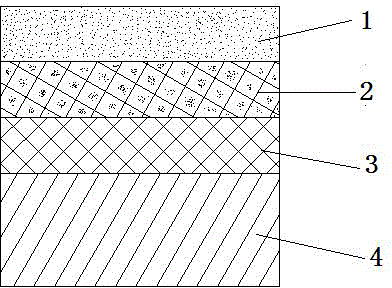

[0054] (1), will contain different contents of tungsten carbide (WC), nickel-chromium alloy powder (Ni 30 Cr 6 ) two-layer coated metal powder wire mesh flexible composite cloth is pasted on the metal substrate with an epoxy resin adhesive, and the order of pasting is that the one with high tungsten carbide (WC) content is close to the surface, and the one with low content is close to the substrate;

[0055] (2) Prepare the BNi-2 brazing material into a solder wire mesh flexible composite cloth and paste it on the coated metal powder flexible wire mesh cloth in step (1);

[0056] (3) Infiltration brazing is carried out in a vacuum furnace. During brazing, the first stage of heating removes the forming agent and binder in the flexible wire mesh cloth containing wear-resistant tungsten carbi...

Embodiment 2

[0066] The method for the tungsten carbide wear-resistant composite coating prepared by the infiltration brazing method described in the present embodiment: comprises the following steps:

[0067] (1), will contain different contents of tungsten carbide (WC), nickel-chromium alloy powder (Ni 30 Cr 6 ) two-layer coated metal powder flexible wire mesh cloth is pasted on the metal substrate with epoxy resin adhesive, and the order of pasting is that the one with high tungsten carbide (WC) content is close to the surface, and the one with low content is close to the substrate;

[0068] (2) Prepare the BNi-2 brazing material into a solder wire mesh flexible composite cloth and paste it on the coated metal powder flexible wire mesh cloth in step (1);

[0069] (3) Infiltration brazing is carried out in a vacuum furnace. During brazing, the first stage of heating removes the forming agent and binder in the flexible wire mesh cloth containing wear-resistant tungsten carbide particles,...

Embodiment 3

[0079] The method for the tungsten carbide wear-resistant composite coating prepared by the infiltration brazing method described in the present embodiment: comprises the following steps:

[0080] (1), will contain different contents of tungsten carbide (WC), nickel-chromium alloy powder (Ni 30 Cr 6 ) two-layer coated metal powder flexible wire mesh cloth is pasted on the metal substrate with epoxy resin adhesive, and the order of pasting is that the one with high tungsten carbide (WC) content is close to the surface, and the one with low content is close to the substrate;

[0081] (2) Prepare the BNi-2 brazing material into a solder wire mesh flexible composite cloth and paste it on the coated metal powder flexible wire mesh cloth in step (1);

[0082] (3) Infiltration brazing is carried out in a vacuum furnace. During brazing, the first stage of heating removes the forming agent and binder in the flexible wire mesh cloth containing wear-resistant tungsten carbide particles,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com