Probiotic milk and preparation method thereof

A technology of probiotic milk and probiotics, applied in dairy products, milk preparations, applications, etc., can solve problems such as undrinkable, protein denaturation and precipitation, and poor product tissue status, and achieve the effect of protein denaturation and multi-nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

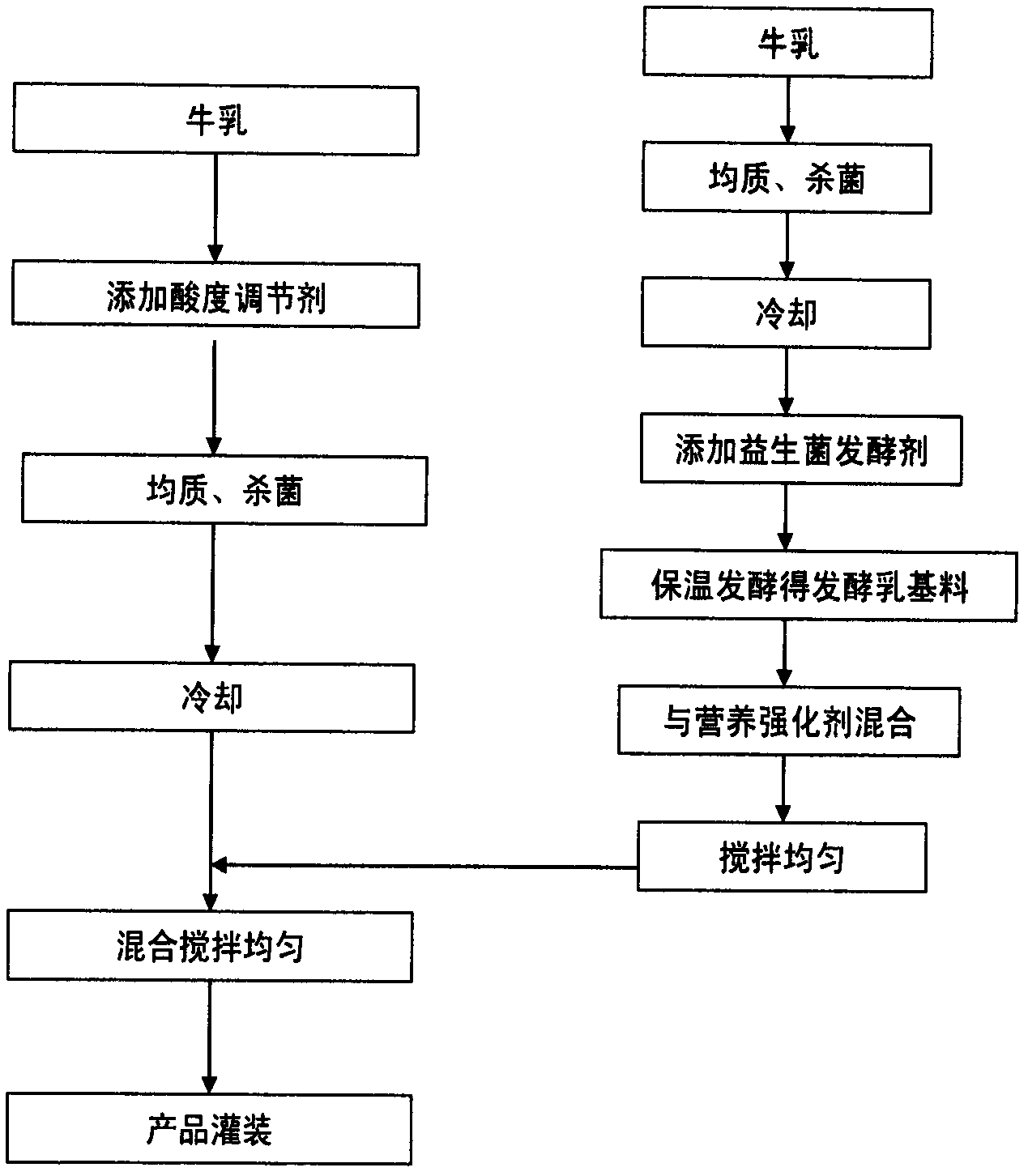

Method used

Image

Examples

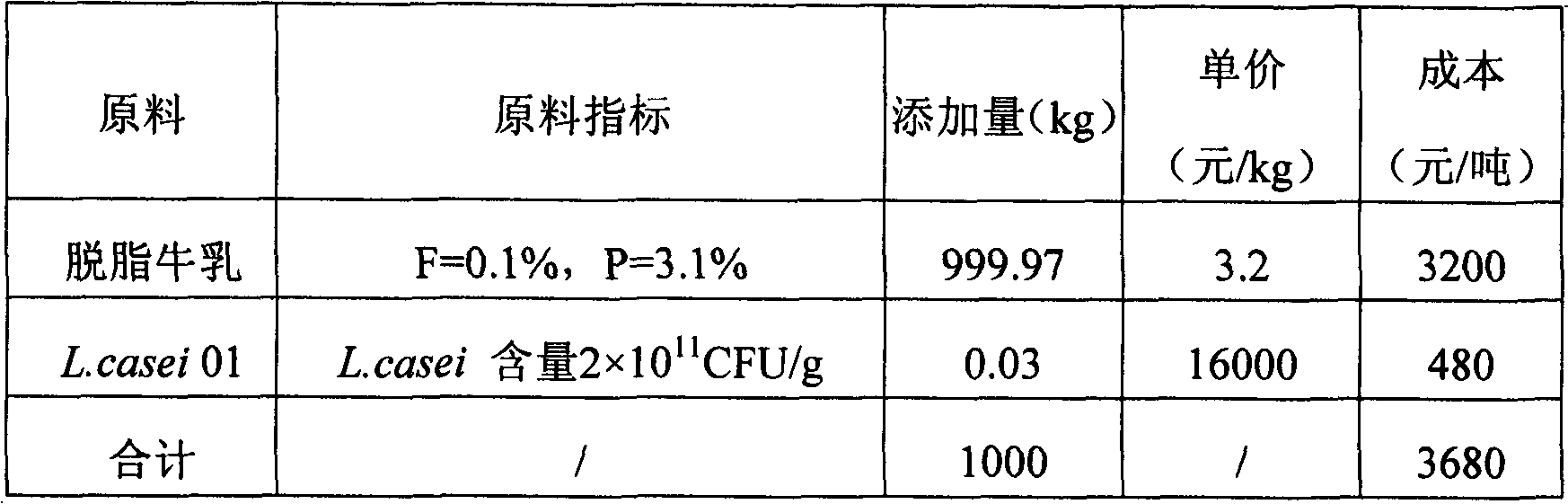

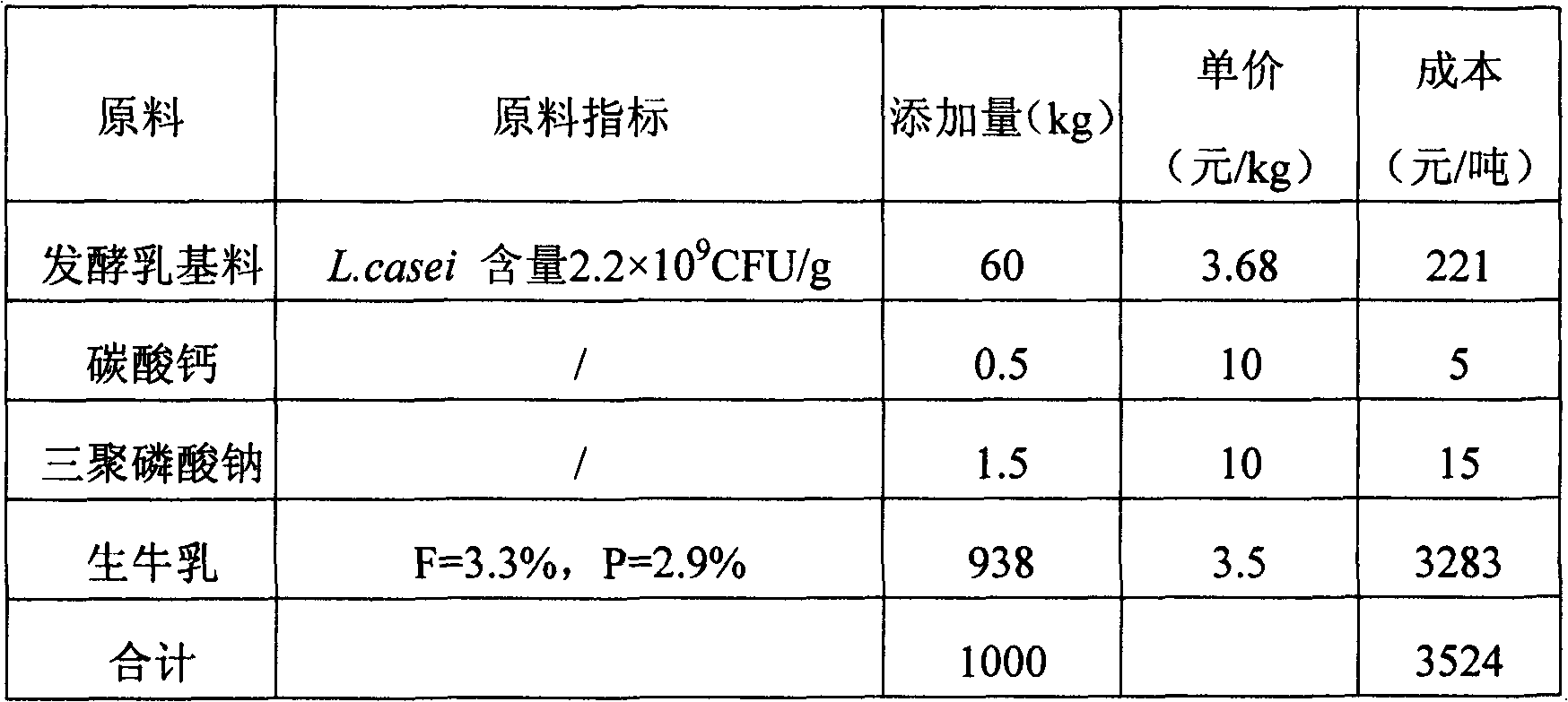

Embodiment 1

[0062] (1) Preparation of composition A:

[0063] Probiotic fermentation: 60 kg of skim milk that passed the antibiotic residue test was sterilized at 96°C for 90 minutes, cooled to 37°C, and then added with 1.8 grams of Lactobacillus casei 01 strain, kept and fermented to a titrated acidity of 240°T to obtain a fermented milk base;

[0064] Nutritional enhancer addition: mix 60 kg of fermented milk base material with 0.5 kg of food-grade sterilized calcium carbonate, and stir evenly to obtain composition A;

[0065] (2) Preparation of composition B:

[0066] Mix 938 kg of raw milk with 1.5 kg of sodium tripolyphosphate, homogenize at 65 °C and 20 MPa, pasteurize at 75 °C for 15 seconds, and cool to 5 °C to obtain composition B;

[0067] (3) mixing:

[0068] Mix and stir the composition A prepared in step (1) and the composition B prepared in step (2) until they are evenly mixed to obtain probiotic milk;

[0069] (4) Product filling and refrigeration:

[0070] Fill the pro...

Embodiment 2

[0080] (1) Preparation of composition A:

[0081] Probiotic fermentation: Mix skim milk powder and purified water according to the formula in Table 4 to prepare reconstituted skim milk, then mix with fructose syrup F42, sterilize at 97°C for 120 minutes, cool to 37°C, and insert L.casei LC2W bacteria Seed 2.5 grams, insulated and fermented to a titrated acidity of 160°T, to obtain a fermented milk base;

[0082] Nutritional enhancer addition: mix the fermented milk base material with 1 kg of sterilized food-grade calcium carbonate, and stir evenly to obtain composition A;

[0083] (2) Preparation of composition B:

[0084] Mix 897.5 kg of raw milk with 1.5 kg of sodium citrate, homogenize at 65°C and 20 MPa, pasteurize at 75°C for 15 seconds, and cool to 5°C to obtain composition B;

[0085] (3) mixing:

[0086] Mix and stir the composition A prepared in step (1) and the composition B prepared in step (2) until they are evenly mixed to obtain probiotic milk;

[0087] (4) P...

Embodiment 3

[0098] (1) Preparation of composition A:

[0099] Probiotic fermentation: 120 kg of raw milk that passed the antibiotic residue test was homogenized at 65°C and 20 MPa, then sterilized at 95°C for 10 minutes, cooled to 39°C, and then added with 6 grams of Lactobacillus acidophilus NCFM starter, and kept for fermentation until Titration acidity 95°T;

[0100] Nutritional enhancer addition: mix the fermented milk base material with 0.5 kg of sterilized food-grade calcium carbonate, and stir evenly to obtain composition A;

[0101] (2) Preparation of composition B:

[0102] Mix 874.4 kg of raw milk, 0.5 kg of sodium tripolyphosphate, 3 kg of microcrystalline cellulose, 0.5 kg of glyceryl monostearate, 0.1 kg of aspartame and 1 kg of HBS749 milk essence, heat up to 60°C and stir to dissolve Thickener and emulsifier, homogenized at 65°C and 20MPa, pasteurized at 75°C for 15s, cooled to 5°C to obtain composition B;

[0103] (3) mixing:

[0104] Mix and stir the composition A pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com