Layer perforation of two-dimensional layer-shaped metal organic framework and application

A metal-organic framework, two-dimensional layered technology, applied in membrane technology, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of easy formation of pinholes or cracks, difficult to enlarge the membrane preparation process, etc., to achieve good gas separation. Performance, simple effect of open-layer method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Six-membered ring two-dimensional ZIF-7 material layer opening

[0036] The pre-synthesized six-membered ring two-dimensional ZIF-7 powder was dried in a vacuum oven at 150°C for 24 hours.

[0037] The layer-opening solution is configured as follows:

[0038] Layer-opening solution: 0.08 g of six-membered ring two-dimensional ZIF-7, 0.2 g of octadecylamine mixed with 40 ml of n-hexane;

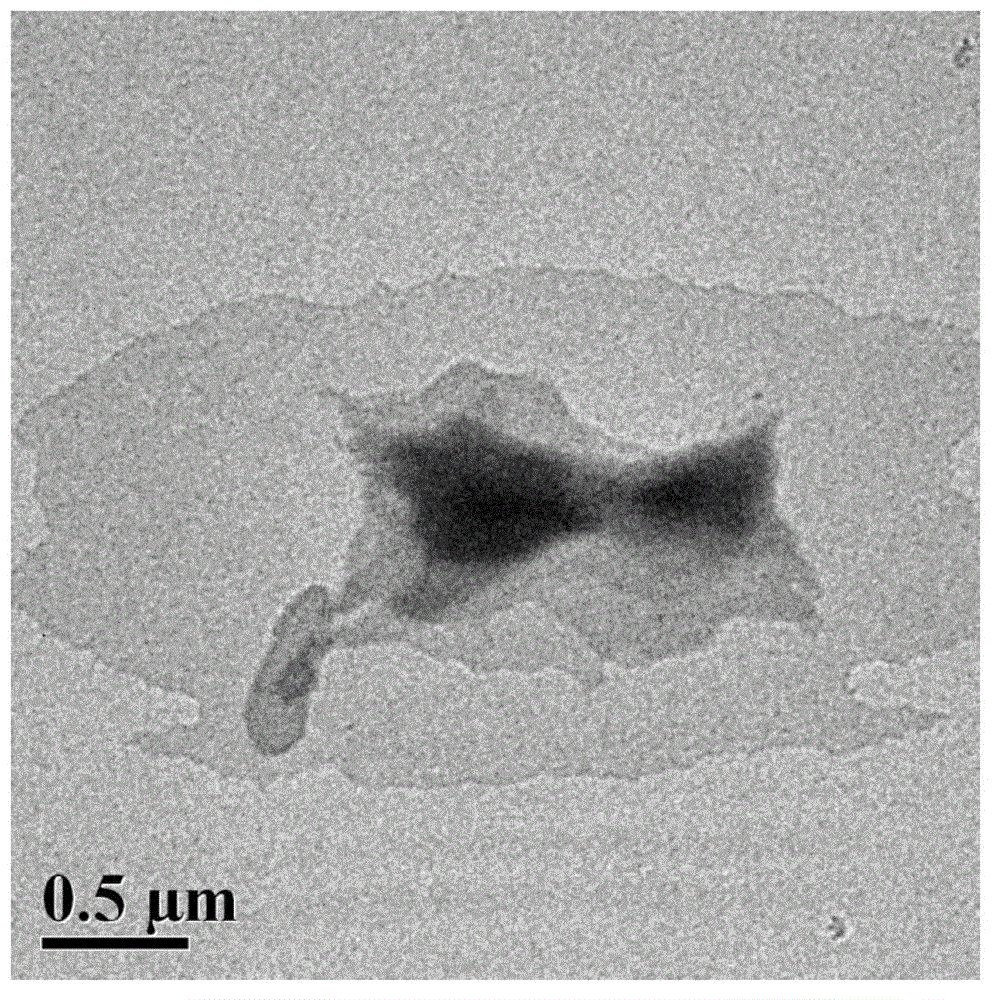

[0039] The prepared mixture was placed in a 600-watt ultrasonic instrument for ultrasonication in a water bath for 30 minutes, and stirred overnight; centrifuged at a speed of 12,000 rpm for 20 minutes; minutes; add 40 ml of n-hexane to the slurry, ultrasonicate at 60 watts for 15 minutes, and centrifuge at 500 rpm for 20 minutes. The resulting TEM image of the supernatant shows that it is a very thin sheet-like material (e.g. figure 1 shown). No obvious X-ray diffraction can be observed, indicating that the obtained ZIF-7 sheet material is very thin.

Embodiment 2

[0040] Example 2 Four-membered ring two-dimensional ZIF-7 material layer opening

[0041] The layer-opening solution is configured as follows:

[0042] Layer-opening solution: 0.005 g of four-membered ring two-dimensional ZIF-7 mixed with 3.75 ml of n-hexane;

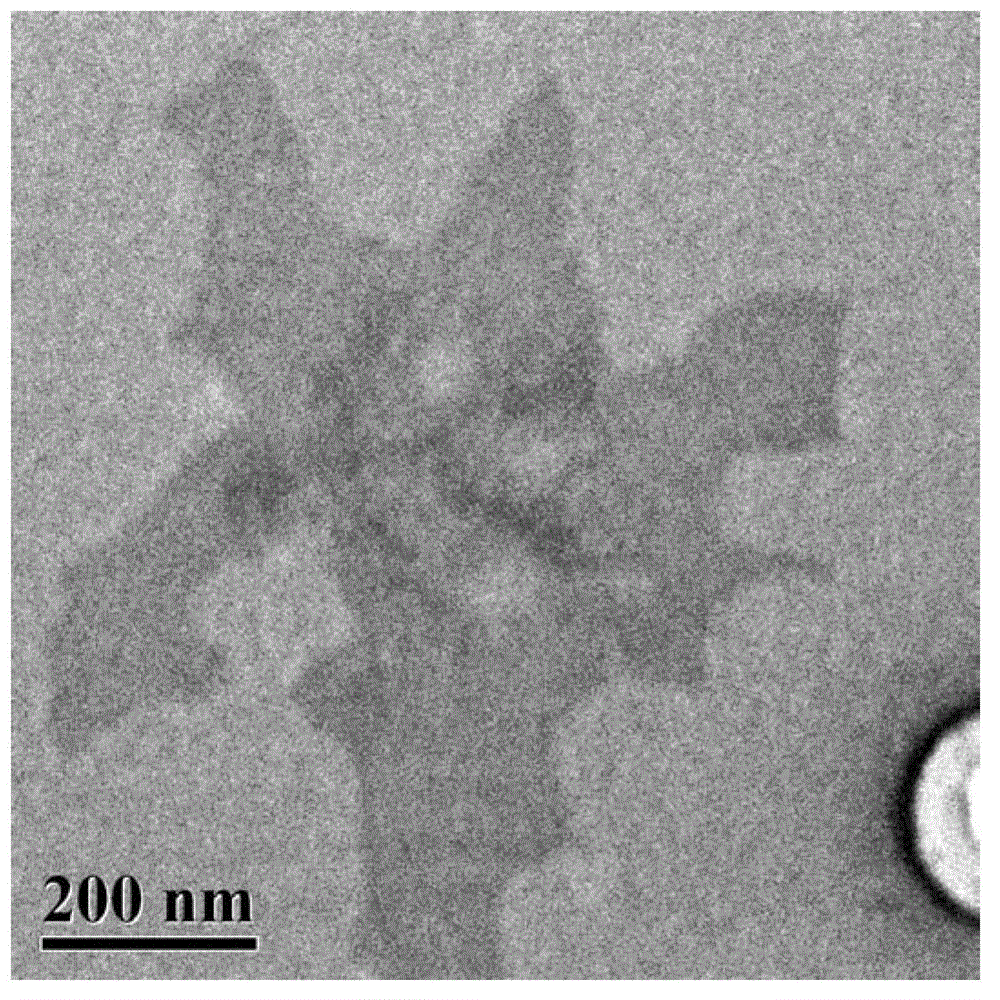

[0043] The prepared mixture was placed in a 600-watt ultrasonic instrument for ultrasonication in a water bath for 50 minutes; centrifuged at a speed of 500 per minute for 10 minutes to remove large particles; the transmission electron microscope image of the obtained supernatant showed that the layer was opened to obtain a very thin sheet material (such as figure 2 shown). No obvious X-ray diffraction can be observed, indicating that the obtained ZIF-7 sheet material is very thin.

Embodiment 3 2

[0044] Example 3 Two-dimensional covalent triazine framework material CTF-1 layer opening

[0045] Layer opening solution: mix 0.05 g of CTF-1 with 40 ml of n-hexane;

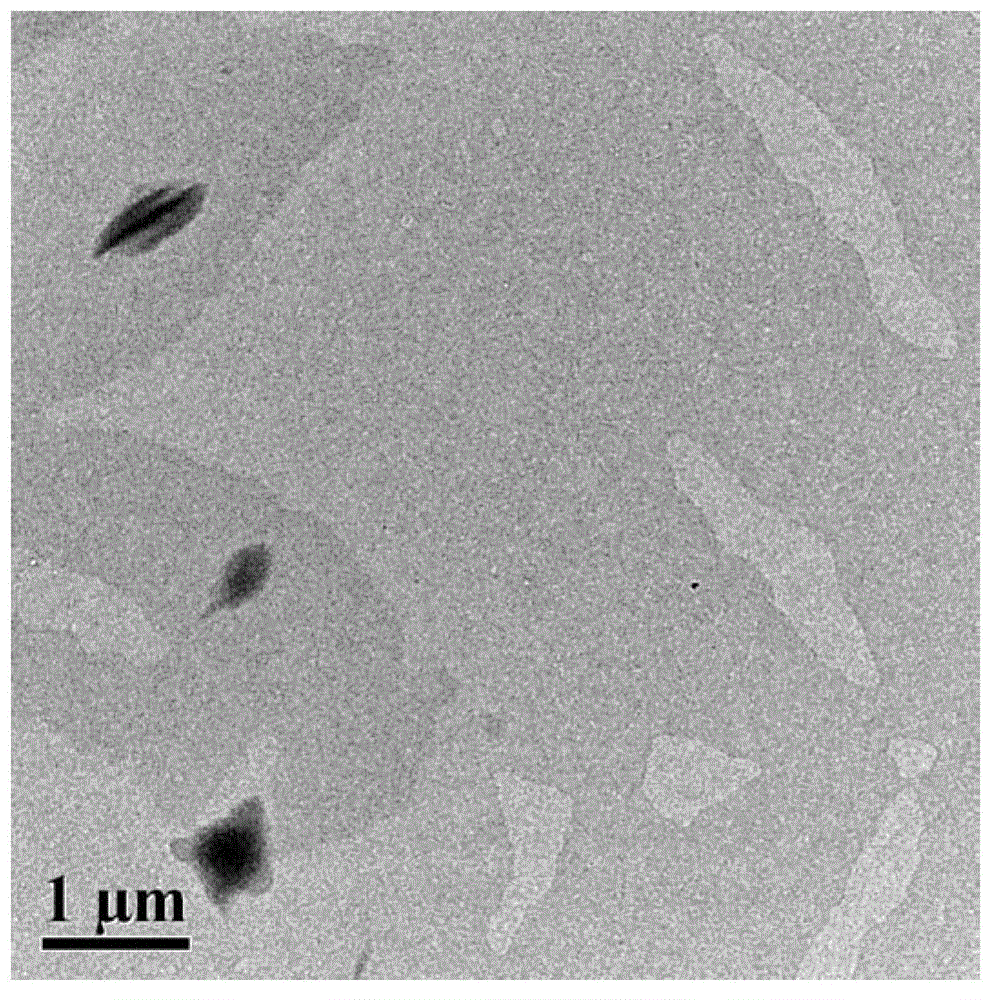

[0046] The prepared mixture was placed in a 600-watt sonicator in a water bath and sonicated for 50 minutes; after standing for 20 minutes, the supernatant was taken. The resulting transmission electron microscope image of the supernatant shows that the delamination yields extremely thin sheet-like materials (e.g. image 3 shown). No obvious X-ray diffraction can be observed, indicating that the obtained CTF-1 sheet material is very thin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com