Special longitudinal seam inside welding machine for stainless steel and composite steel welded pipes and use and using method of special longitudinal seam inside welding machine

A technology of stainless steel and composite steel, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high labor intensity, low processing efficiency, and not less than 500 mm, and achieve simple control and processing accuracy The effect of high height and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

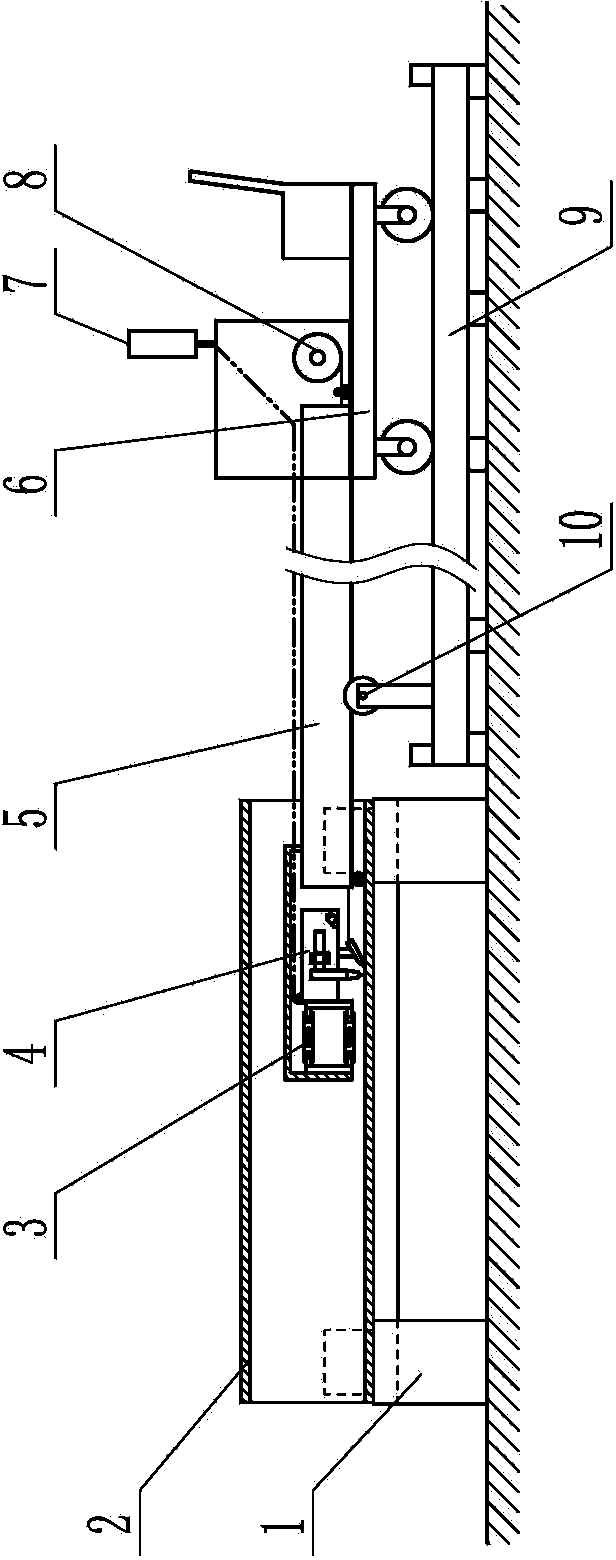

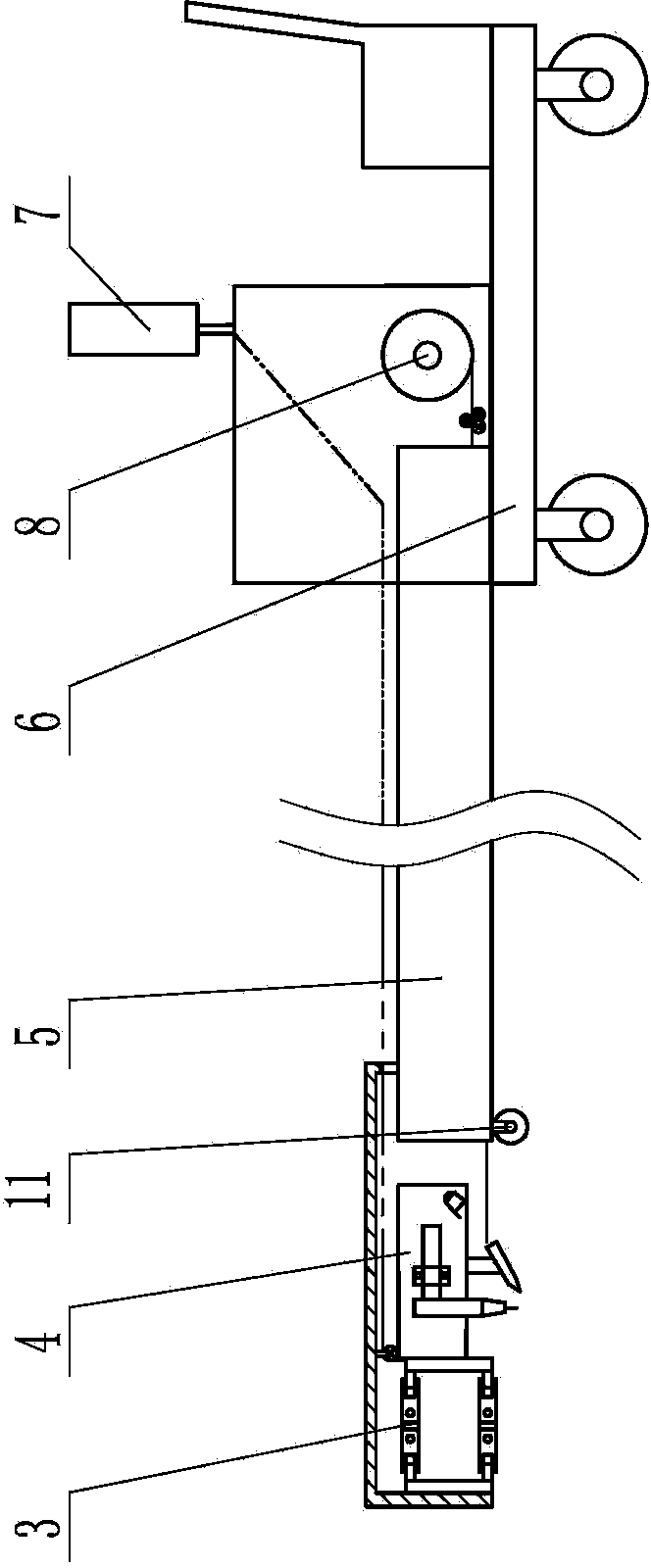

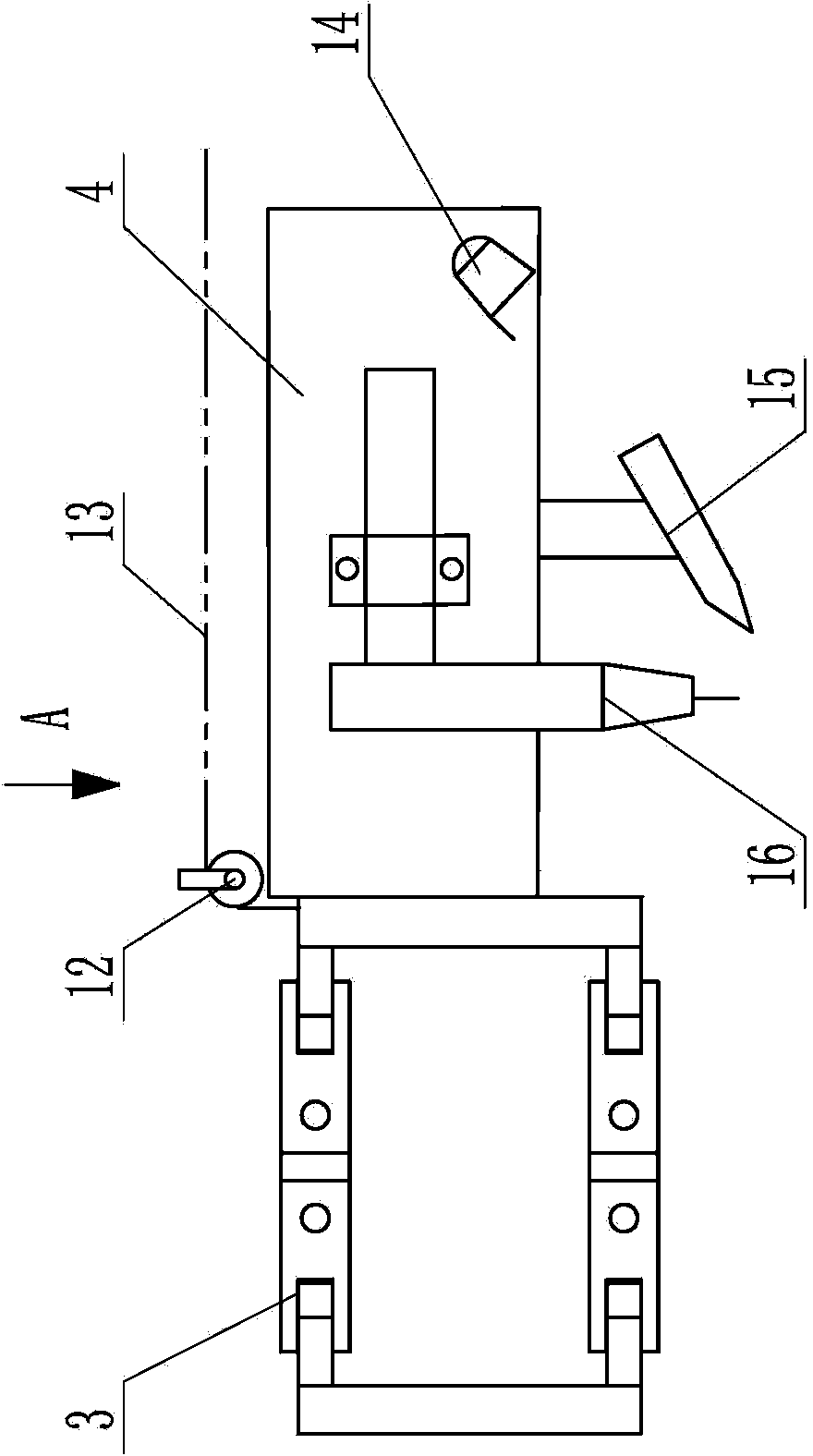

[0042] Such as figure 1 and 2 As shown, in the present invention, one end of the welding arm 5 is connected to the mounting plate 4 through the universal joint 3 , and the welding torch 16 and the wire feeding nozzle 15 are fixed on the mounting plate 4 . The other end of welding arm 5 is fixed on the mobile dolly 6. The controller 7 is also installed on the mobile trolley 6, and the controller 7 is connected to control the starting and closing operation of the welding machine and the wire feeder 8, the adjustment work of the welding torch fine-tuning device and the real-time monitoring situation of the welding task by the video monitoring device.

[0043]The upper fixed pulley 12 and the side fixed pulley 18 of the welding torch fine-tuning device are all installed on the welding arm 5 . The up-and-down movement of the welding tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com