Warm-mixing agent used for waste-rubber-powder-modified asphalt, and preparation method thereof

A technology of modified asphalt and warm mix agent, which is applied in the direction of climate change adaptation, etc., which can solve the problems of water bubbles, lower low-temperature performance, and dependence on network chain structure, etc., and achieve excellent viscosity reduction effect and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

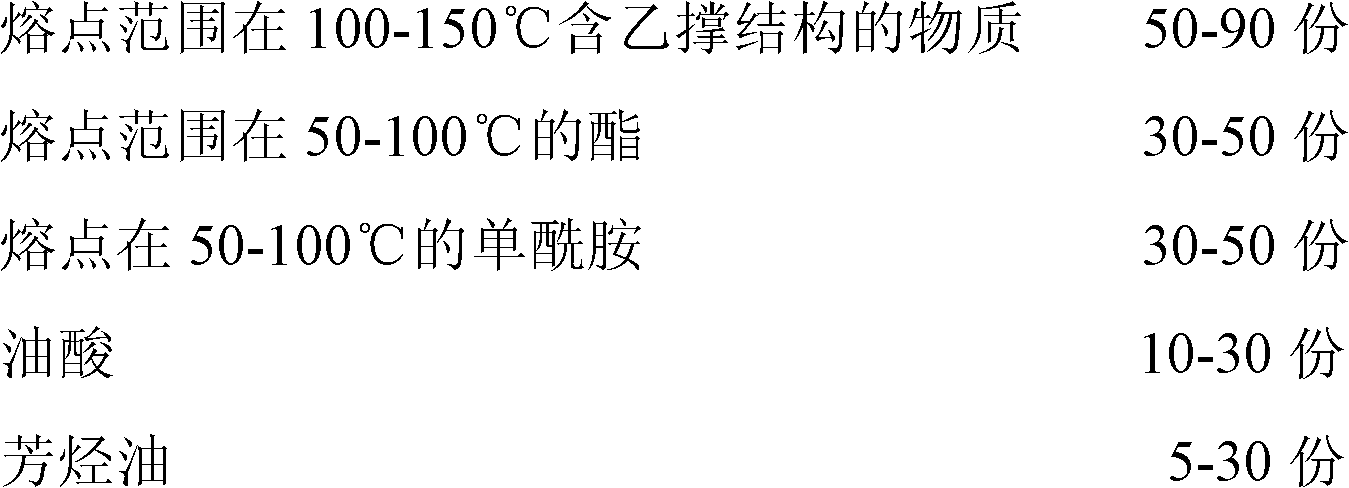

[0022] With 50 mass parts of ethylene bisoleic acid amide, 30 mass parts of diphenyl carbonate, 30 mass parts of oleic acid amide, 15 mass parts of oleic acid, aromatic oil (Zibo Taichang Lubricating Oil Co., Ltd., the following examples all adopt the same Aromatic oil) 5 parts by mass are preliminarily mixed to make it macroscopically uniform. Then, the primary mixture was put into a reactor (volume 5L, the same reactor was used in the following examples) for reaction and mixing, the stirring speed was 50r / min, and the treatment time was 15 minutes at 140°C, and cooled to room temperature. Get warm mix.

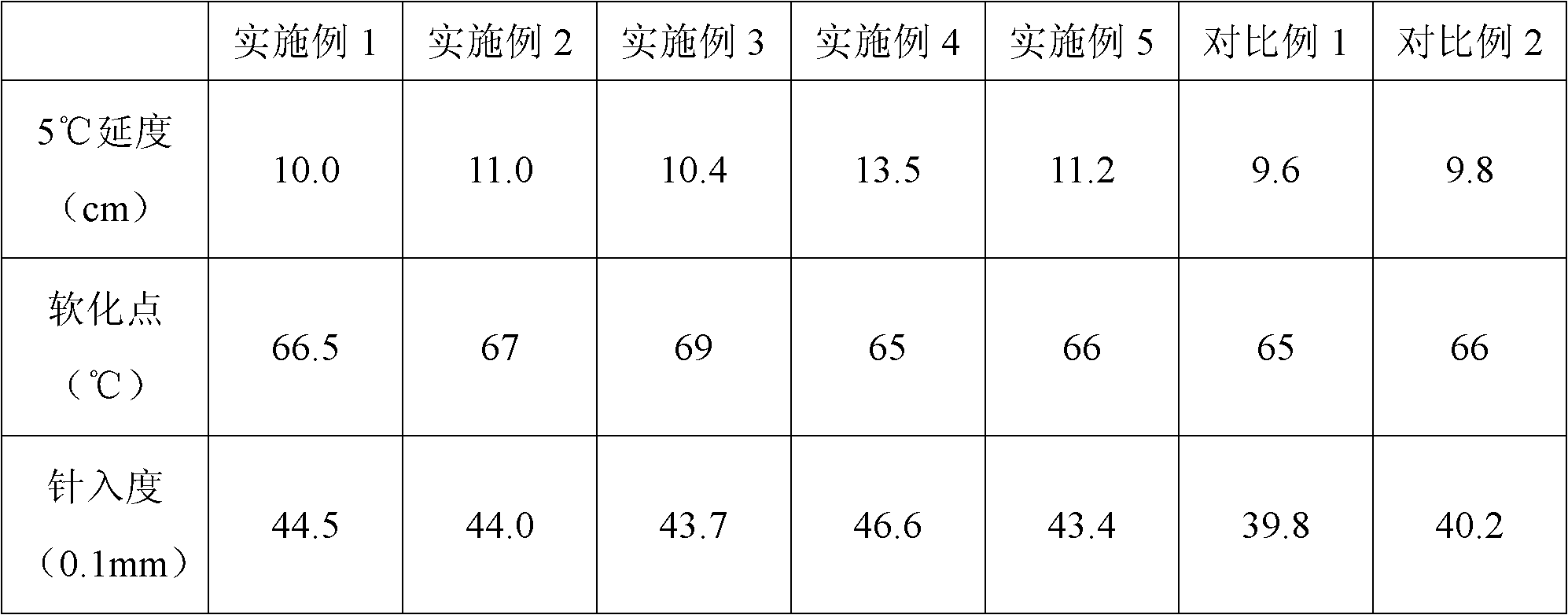

[0023] Add warm mix agent and modified asphalt to the modified asphalt prepared in Comparative Example 1 at a mass ratio of 1:50, and stir with a high-speed mixer at 160°C for 15 minutes at a stirring speed of 300r / min. The resulting viscosity is shown in Table 1, and other performance indicators are shown in Table 2.

Embodiment 2

[0025] 50 parts by mass of ethylene bis stearic acid amide, 30 parts by mass of glyceryl monostearate, 30 parts by mass of oleic acid amide, 15 parts by mass of oleic acid and 5 parts by mass of aromatic oil are preliminarily mixed to achieve macroscopic uniformity. Then, put the primary mixture into the reaction kettle for reaction and mixing, the stirring speed is 50r / min, the treatment time is 15 minutes at 140°C, and cooled to room temperature to prepare the warm mixing agent.

[0026] Add warm mix agent and modified asphalt to the modified asphalt prepared in Comparative Example 1 at a mass ratio of 1:50, and stir with a high-speed mixer at 160°C for 15 minutes at a stirring speed of 300r / min. The resulting viscosity is shown in Table 1, and other performance indicators are shown in Table 2.

Embodiment 3

[0028] Preliminarily mix 50 parts by mass of ethylene bisoleamide, 30 parts by mass of glyceryl behenate, 30 parts by mass of erucamide, 15 parts by mass of oleic acid, and 5 parts by mass of aromatic oil to achieve macroscopic uniformity. Then, put the primary mixture into the reaction kettle for reaction and mixing, the stirring speed is 50r / min, the treatment time is 15 minutes at 140°C, and cooled to room temperature to prepare the warm mixing agent.

[0029] Add warm mix agent and modified asphalt to the modified asphalt prepared in Comparative Example 1 at a mass ratio of 1:50, and stir with a high-speed mixer at 160°C for 15 minutes at a stirring speed of 300r / min. The resulting viscosity is shown in Table 1, and other performance indicators are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com