Technique for producing macroelement water-soluble fertilizer and coproducing slow-release fertilizer

A water-soluble fertilizer and a large amount of element technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problem of high production cost, achieve the effect of low production cost, less investment in equipment, and long-lasting fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

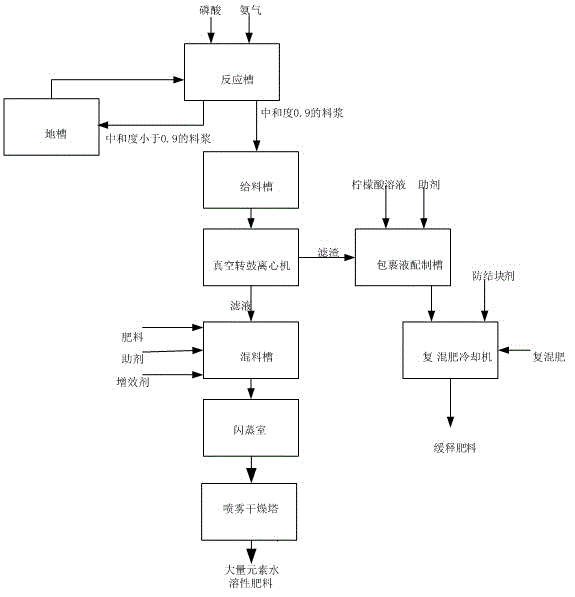

[0023] Example 1: The production process of slow-release fertilizer co-production of water-soluble fertilizer with a large number of elements

[0024] A. Start the phosphoric acid pump, put 6000L ω(P 2 o 5 ) 22% wet-process phosphoric acid into the reaction tank, and when the lower blade of the stirring paddle is submerged, start the stirring paddle.

[0025] B. Reduce the flow rate of phosphoric acid, slowly open the valve on the ammonia pipeline, and add ammonia to the reaction tank. The slurry with a neutralization degree of <0.9 is put into the ground tank, and after the production is normal, it is put into the reaction tank to continue neutralization. Measure the degree of neutralization every 5 minutes, adjust the flow rate of phosphoric acid and ammonia gas until the degree of neutralization reaches 0.9, and put the neutralized slurry into the feed tank.

[0026] C. Put the slurry in step B into a vacuum drum centrifuge with automatic discharge for separation, put th...

Embodiment 2

[0033] Example 2: The production process of slow-release fertilizer co-production of water-soluble fertilizer with a large number of elements

[0034] A. Start the phosphoric acid pump, put 6000L ω(P 2 o 5 ) 22% wet-process phosphoric acid into the reaction tank, and when the lower blade of the stirring paddle is submerged, start the stirring paddle.

[0035] B. Reduce the flow rate of phosphoric acid, slowly open the valve on the ammonia pipeline, and add ammonia to the reaction tank. The slurry with a neutralization degree of <0.9 is put into the ground tank, and after the production is normal, it is put into the reaction tank to continue neutralization. Measure the degree of neutralization every 5 minutes, adjust the flow rate of phosphoric acid and ammonia gas until the degree of neutralization reaches 0.9, and put the neutralized slurry into the feed tank.

[0036]C. Put the slurry in step B into a vacuum drum centrifuge with automatic discharge for separation, put the...

Embodiment 3

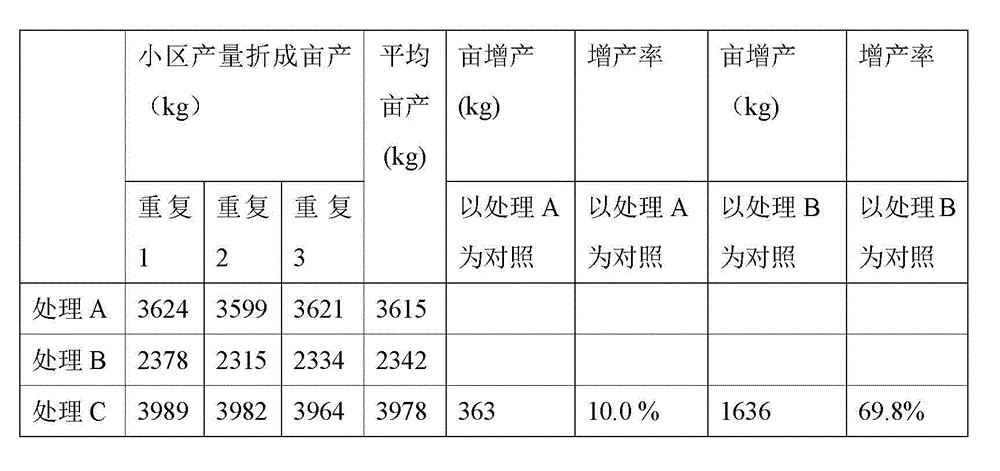

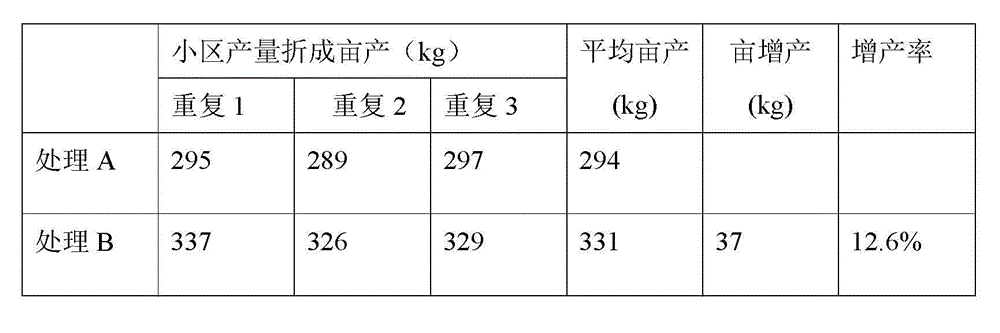

[0041] Embodiment 3: The water-soluble fertilizer produced by the production process of Embodiment 1 or 2 was carried out in field fertilizer effect test in Wuzhuang Village, Shanzuokou Township, Donghai County, Jiangsu Province

[0042] 1. Test material: a large amount of elemental water-soluble fertilizer produced by the production process of embodiment 1 or 2;

[0043] Potassium sulfate compound fertilizer (15-15-15).

[0044] 2. The tested crop: hot pepper

[0045] 3. Test soil: The soil of the test site is sandy loam with medium fertility.

[0046] 4. Test conditions:

[0047] Treatment A: 50kg of potassium sulfate compound fertilizer (15-15-15) was applied as base, 40% was sprinkled before soil preparation, and 60% was applied to the planting ditch.

[0048] Treatment B: no fertilization.

[0049] Treatment C: In addition to the fertilization of treatment A, water-soluble fertilizers with macroelements were sprayed once at the seedling stage, the initial flowering st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com