C-grade modified bismaleimide glass fiber reinforced mould plastic

A technology of bismaleimide glass fiber and bismaleimide resin, which is applied in the field of molding compounds and can solve problems such as unsatisfactory heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

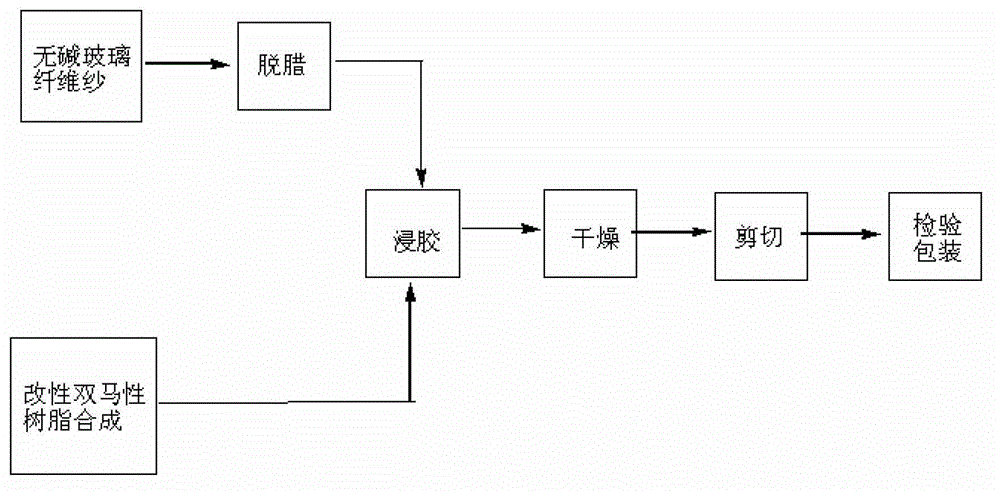

Method used

Image

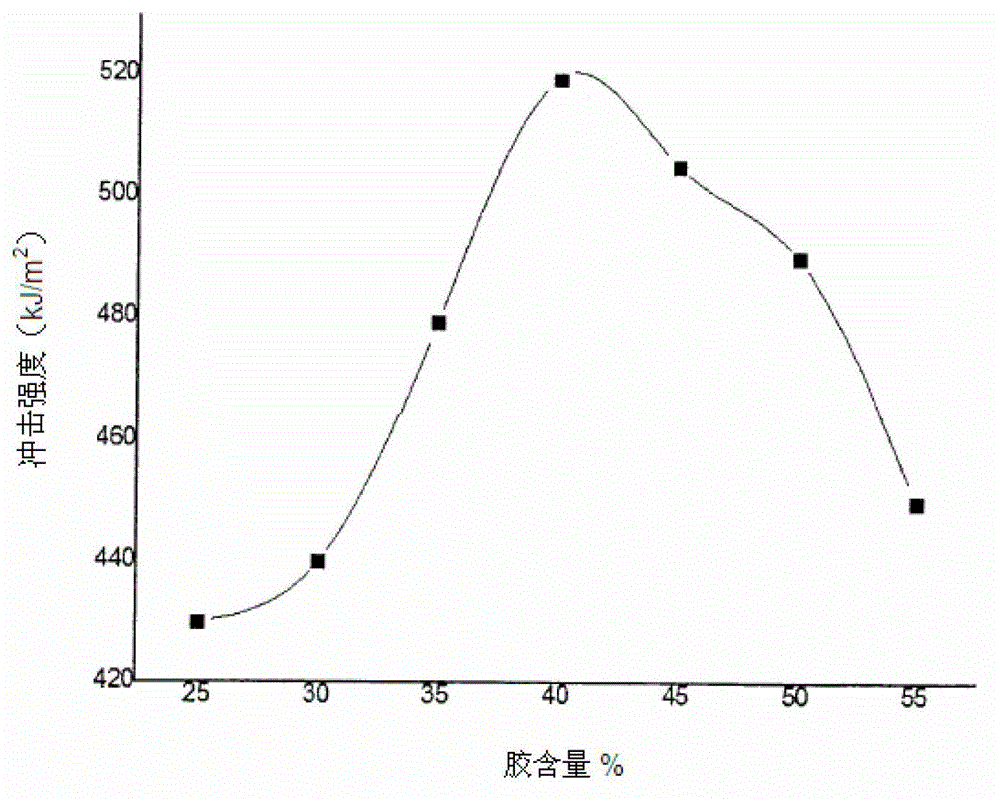

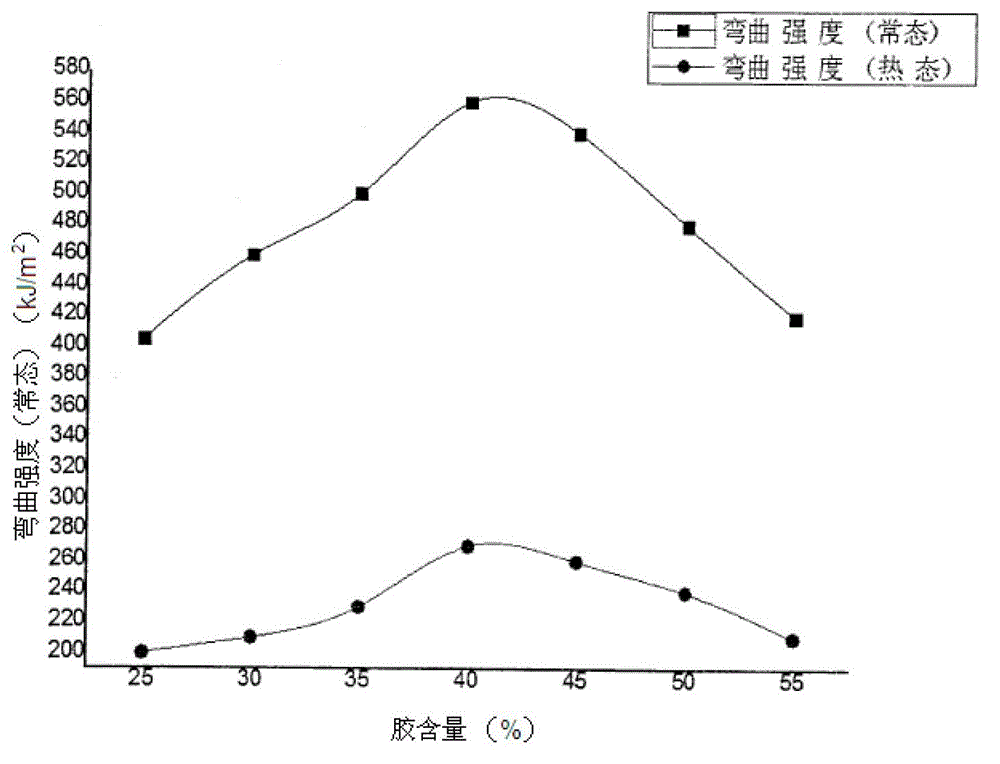

Examples

Embodiment

[0037] 1. The ratio of modified bismaleimide resin

[0038] Table 1 is the proportioning of modified bismaleimide resin

[0039] Table 1

[0040] components parts by mass Bismaleimide (BMI) 7.9 4,4’-Diphenylsulfonediamine (DDS) 4.6 Diaminodiphenyl ether (DDE) 4.6 Heat-resistant epoxy resin F-51 21 toluene 34.1 imidazole 0.6

[0041] The preparation method of this modified bismaleimide resin comprises the following steps:

[0042] (1) Add bismaleimide, 4,4'-diphenylsulfonediamine, and toluene into the reaction kettle in a certain order, heat up to 125°C, stir and reflux, keep warm for 1.5 hours, then cool down to 90°C ℃.

[0043] (2) Add the formula amount of diaminodiphenyl ether, and continue to heat up to? °C, stirred and refluxed for 1 h, distilled 1 / 2 mass ratio of toluene.

[0044] (3) Cool down to 100°C, add heat-resistant epoxy resin in the prescribed amount, keep warm at 90-100°C for 0.5h, cool down to 85°C, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com